Composition for controlling organic pollutant sedimentation during pulping and papermaking production and papermaking method

An organic pollutant, pulping and papermaking technology, applied in the field of pulping and papermaking, can solve the problems of large composition changes, unsatisfactory effects, limited effectiveness, etc., and achieve the effects of reducing viscosity, eliminating deposition problems, and reducing negative effects and hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

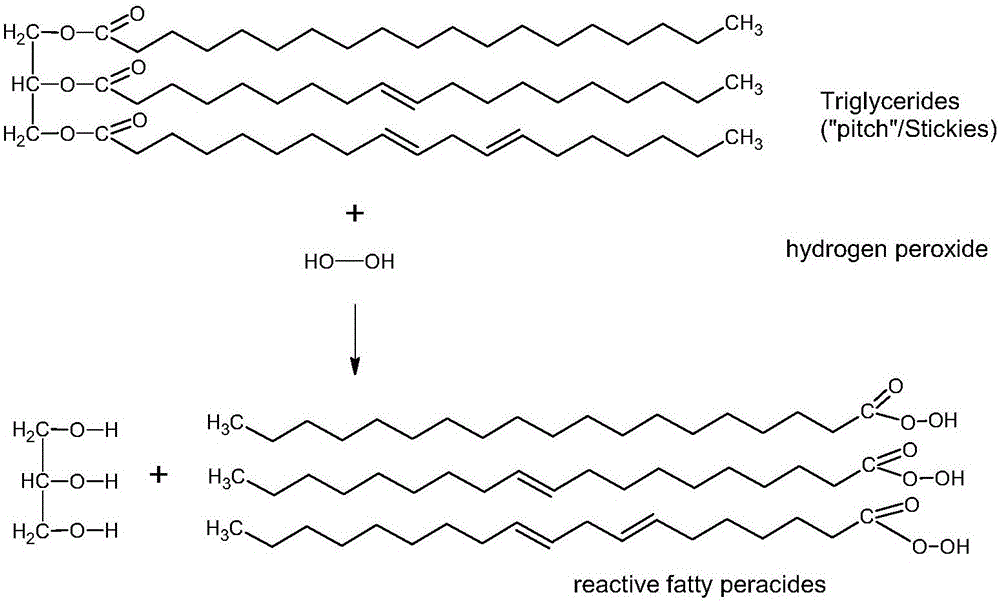

[0100] A papermaking method for controlling the deposition of organic pollutants in pulp and papermaking production, the method is mainly used for the control of organic pollutants (ie, the following stickies) in the process of producing newsprint by recycling waste newspapers.

[0101] 1. Materials

[0102] The pulp of deinked old newspaper pulp (ONP) was obtained from a newsprint paper mill in Guangdong. The conventional sticky matter control agent adopts the registered trademark product of Ashland Company of the United States For reference comparison. Except for the comparative StickyAway (polyvinyl acohol acetate-esterase) which was provided by Novozymes in the United States, biological enzyme products such as perhydrolase and other oxidases and hydrolases were all provided by Ruichenxing Biotechnology (Guangzhou) Provided by Co., Ltd., the number behind is the internal enzyme code of the company. Hydrogen peroxide (30% W / V concentration) and peracetic acid were provid...

Embodiment 2

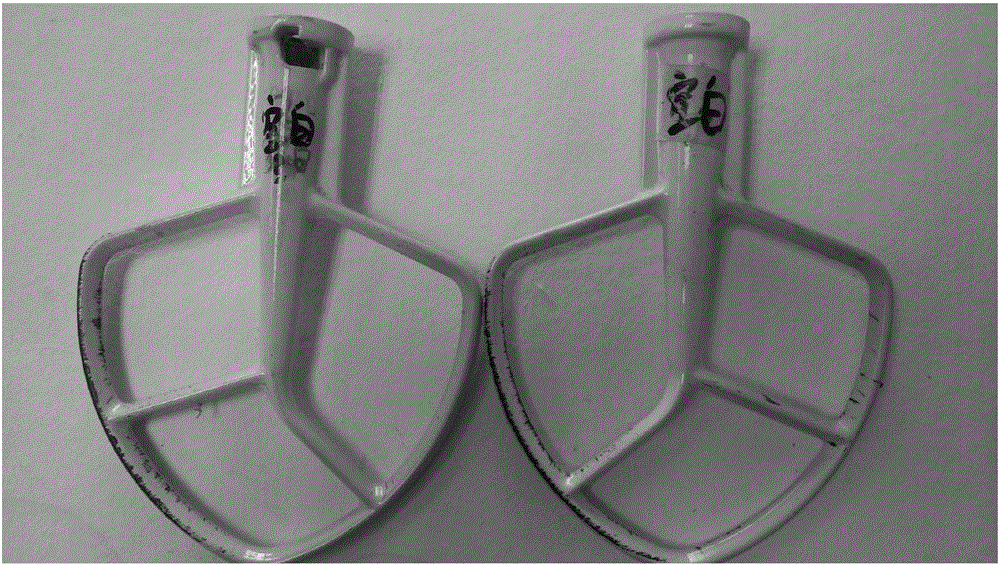

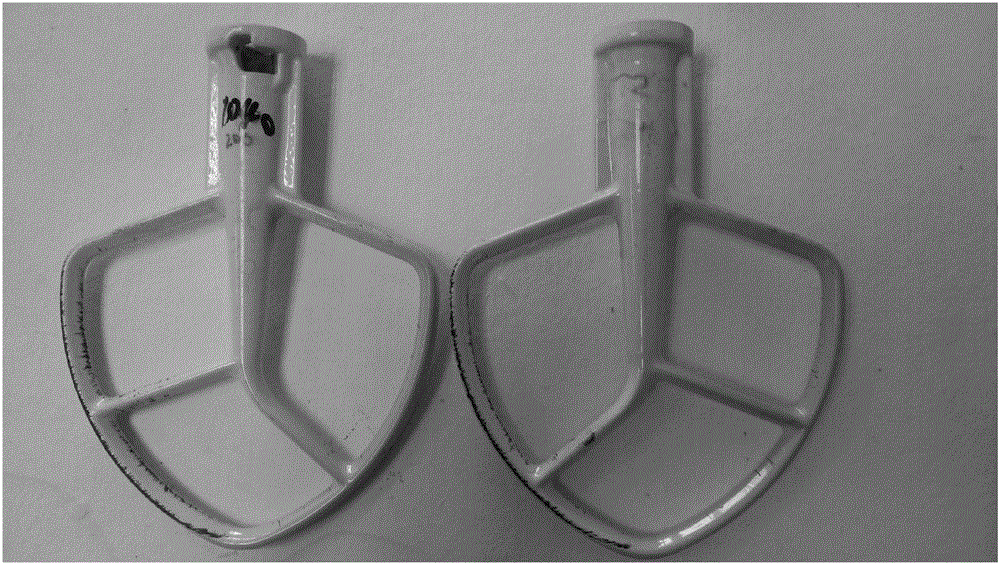

[0116] A large packaging paper manufacturer in East China produces corrugated paper and containerboard. In recent years, the stickiness of recycling OCC waste paper has become increasingly serious. The company had tried a variety of sticky control products without satisfactory results. According to the raw material produced by this paper mill, the sticky matter composition and process conditions, the composition formula of multiple perhydrolase has been tested in the laboratory, and finally an optimal composition is selected (experimental group 4 in embodiment 1, the cleansing enzymes described below TM ) machine test, and carried out a period of nearly two months of direct comparison with sticky substance control enzymes based on StickyAway products (U.S. Buckman products, trade name Maxizyme). The results are shown in Table 2 and Figure 7-8 shown.

[0117] The results in Table 2 show that at the same cost of use, the clean enzyme based on perhydrolase TM Much better th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com