Green mud organic biological compound fertilizer and its preparation method

A compound fertilizer and green mud technology, applied in the direction of organic fertilizers, fertilizer forms, fertilization devices, etc., can solve the problems of non-direct utilization, secondary pollution of toxic and harmful substances, etc., and achieve low cost, wide application and obvious effect of increasing production Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

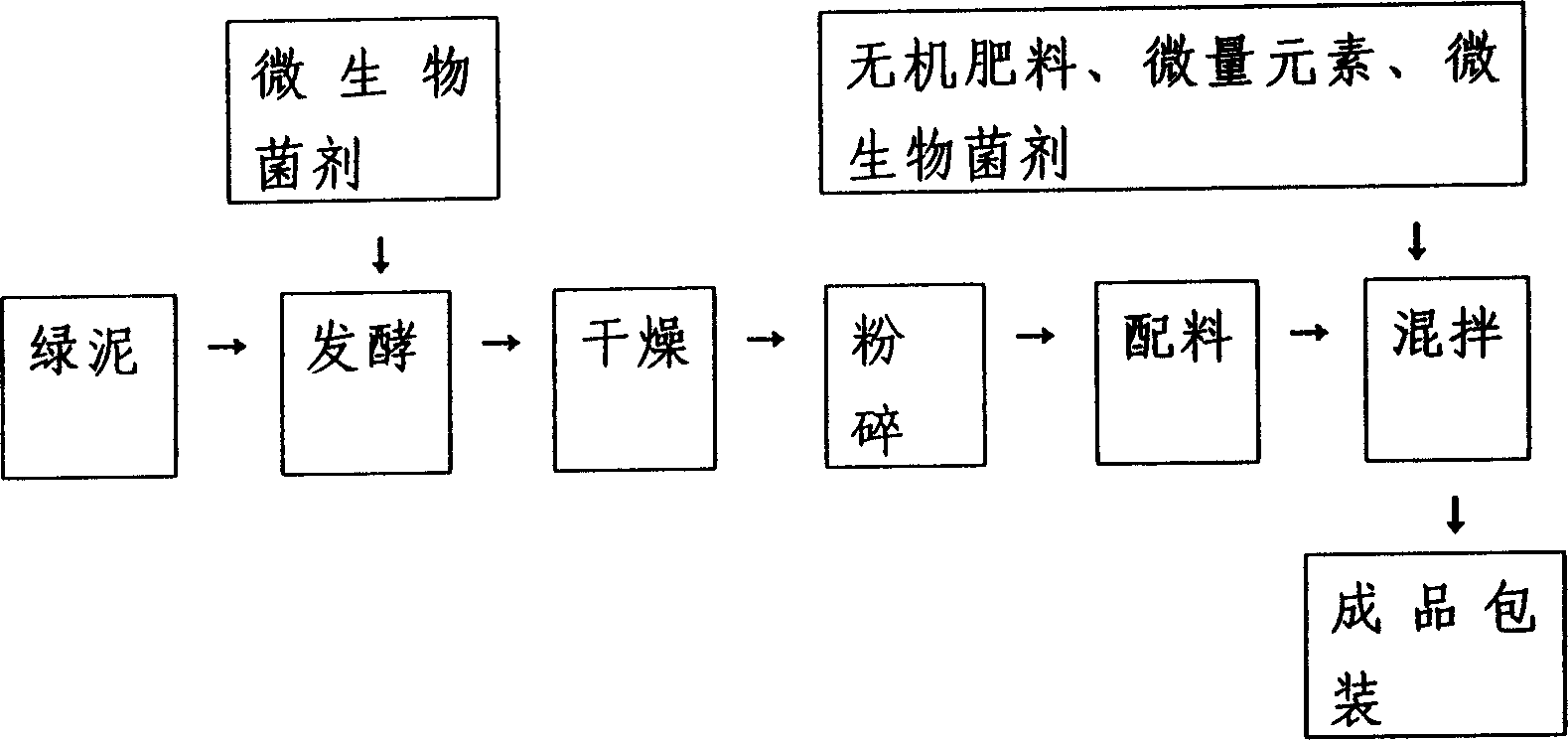

Embodiment 1

[0027] First spread the green mud on the leveled land, with a thickness of 60cm, spray the microbial agent based on enzyme bacteria on the green mud, ferment and dry it; when the water content is 33%, detect its nutrient content , calculated as dry matter: nitrogen 6-7%, phosphorus 1-2%, potassium 1-2%, protein 1517%, fat 10-15%, sugar 8-10%.

[0028] By 55% green mud after fermentation, 39.9% of chemical fertilizers, 5% of trace elements, 0.1% ratio of microbial bacterial agent, wherein in the bacterial agent, enzyme bacteria: nitrogen-fixing bacteria: phosphorus-solubilizing and potassium-decomposing bacteria weight ratio is 5 : 3.0: 6.5; put the above-mentioned raw materials together into a mixer and mix evenly; make powdery green clay bio-organic-inorganic compound fertilizer.

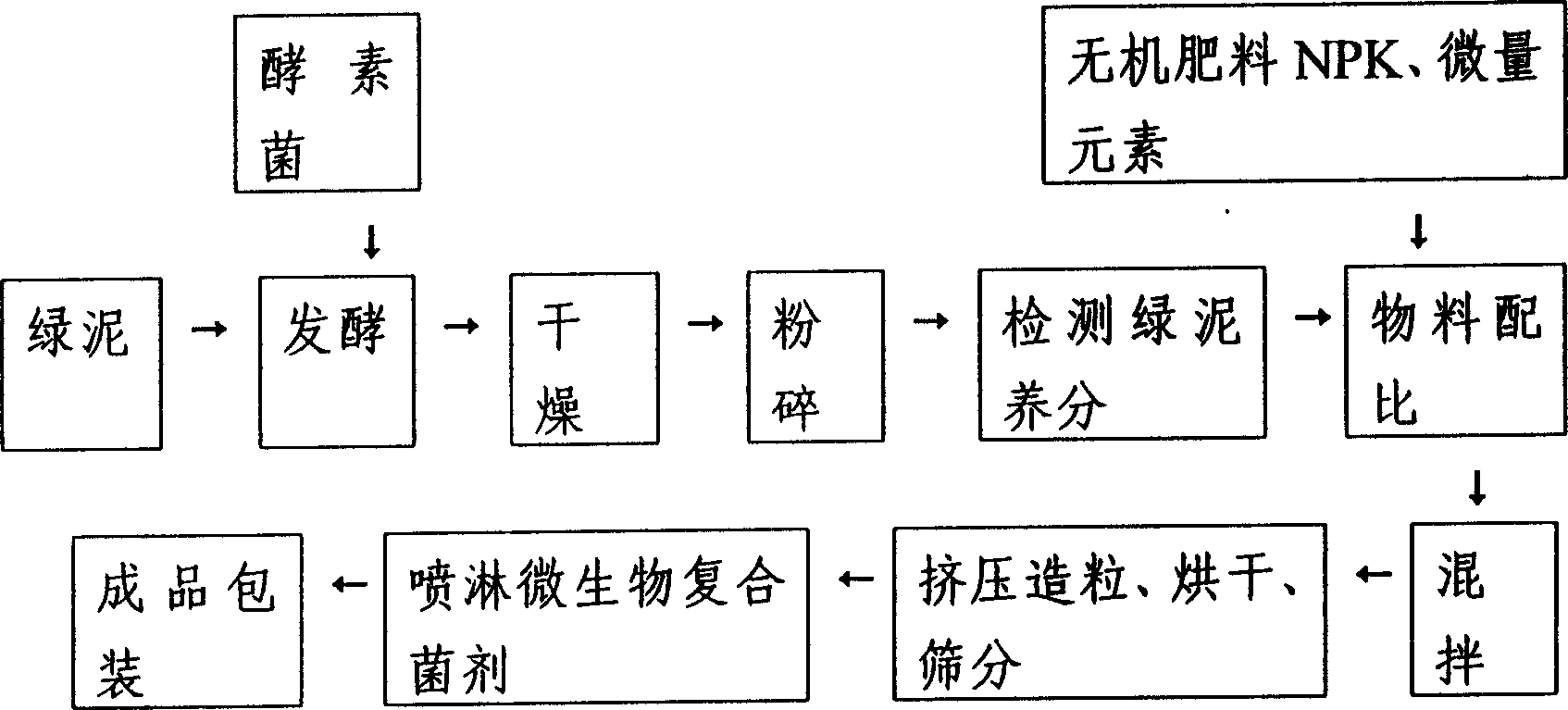

Embodiment 2

[0030] Spread the green mud on the leveled land with a thickness of 90cm, spray the microbial agent based on enzyme bacteria on the green mud, ferment and dry. When the water content is 40%, detect its nutrient content, calculated by dry matter: 5-6% nitrogen, 0.6-1.5% phosphorus, 0.6-1.5% potassium, 12-15% protein, and 8-10% fat 12%, containing 5-6.5% sugar.

[0031] According to the ratio of 65% of fermented green mud, 33.5% of chemical fertilizer, and 1% of trace elements, the above raw materials are put into a mixer and mixed evenly. Through extrusion granulation and drying, the aqueous solution of microbial flora is sprayed on the granular fertilizer by spraying method at the discharge port. The amount of microbial bacterial agent is 0.5% of the total weight of the fertilizer. The weight ratio of bacteria: nitrogen-fixing bacteria: phosphorous and potassium-solubilizing bacteria is 7:1.5:4.5; the granular green mud bio-organic-inorganic compound fertilizer is made.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com