Lignin slow-release water-soluble fertilizer and preparation method thereof

A technology of lignin, water-soluble fertilizer, applied in the preparation of organic fertilizer, sewage/sludge fertilizer, organic fertilizer, etc. problem, to achieve the effect of easy operation, maintaining high activity and low noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

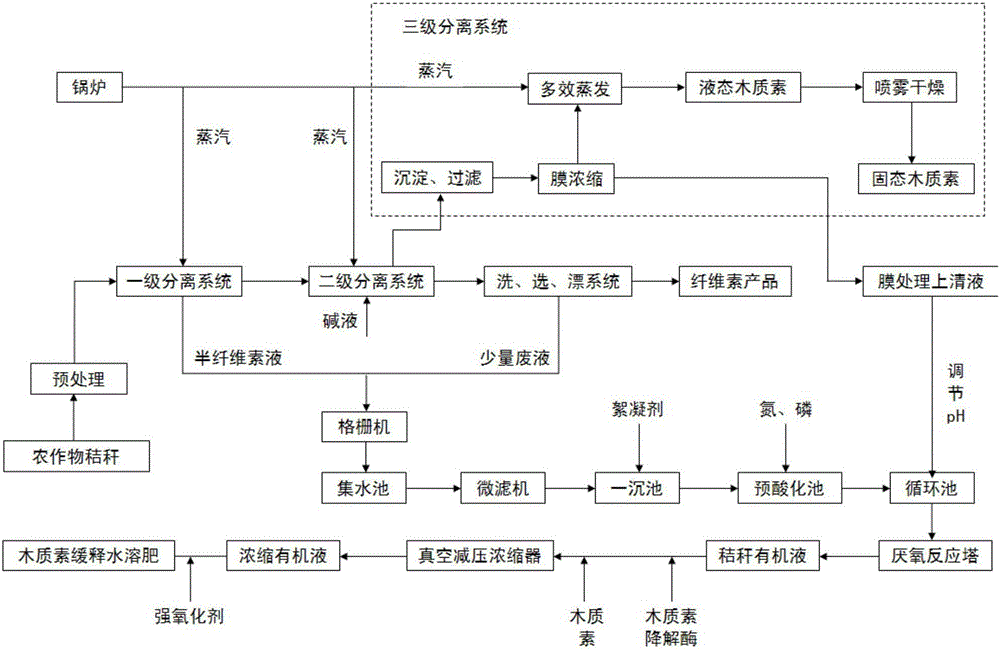

Method used

Image

Examples

Embodiment 1

[0056] (1) Add straw organic liquid, solid lignin and lignin degrading enzyme into the reactor according to the mass ratio of 60:10:1.

[0057] (2) Seal the reaction kettle after feeding, control the temperature at 40°C, mix and stir for 4 hours to obtain a mixed solution;

[0058] (3) Transfer the mixed liquid obtained in step (2) to a vacuum decompression concentrator for concentration to obtain a concentrated organic liquid with a water content of 80% and an organic matter content of 5%.

[0059] (4) Adding a strong activator to the concentrated organic liquid obtained in step (3), activating it while oxidizing it, and preparing a lignin slow-release water-soluble fertilizer.

[0060] The lignin degrading enzyme used is manganese peroxidase, which is a commercially available product.

[0061] The strong activator used is sodium hypochlorite, which is a commercially available product, and the addition amount is 2% relative to the quality of the concentrated organic liquid. ...

Embodiment 2

[0065] (1) Add straw organic liquid, solid lignin and lignin degrading enzyme into the reactor according to the mass ratio of 75:25:2.

[0066] (2) Seal the reaction kettle after feeding, control the temperature at 40°C, mix and stir for 4 hours to obtain a mixed solution;

[0067] (3) Transfer the mixed liquid obtained in step (2) to a vacuum decompression concentrator for concentration to obtain a concentrated organic liquid with a water content of 80% and an organic matter content of 5%.

[0068] (4) Adding a strong activator to the concentrated organic liquid obtained in step (3), activating it while oxidizing it, and preparing a lignin slow-release water-soluble fertilizer.

[0069] The lignin degrading enzyme used is lignin peroxidase, a commercially available product.

[0070] The strong activator used is calcium hypochlorite, a commercially available product, and the addition amount is 4% relative to the mass of the concentrated organic liquid.

[0071] The solid lig...

Embodiment 3

[0074] (1) Add straw organic liquid, solid lignin and lignin degrading enzyme into the reactor according to the mass ratio of 60:10:1.

[0075] (2) Seal the reaction kettle after feeding, control the temperature at 40°C, mix and stir for 4 hours to obtain a mixed solution;

[0076] (3) Transfer the mixed liquid obtained in step (2) to a vacuum decompression concentrator for concentration to obtain a concentrated organic liquid with a water content of 80% and an organic matter content of 5%.

[0077] (4) Adding a strong activator to the concentrated organic liquid obtained in step (3), activating it while oxidizing it, and preparing a lignin slow-release water-soluble fertilizer.

[0078] The lignin degrading enzyme used is a mixture of manganese peroxidase and laccase, the mass ratio of which is 1:1, and the manganese peroxidase and laccase are commercially available products.

[0079] The strong activator used is ethyl hypochlorite, a commercially available product, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com