A method for controlling the deposition of stickies in pulping and papermaking processes

A sticky matter, pulping technology, applied in textiles and papermaking, preventing corrosion/sediment formation of pulping equipment, pulping with organic compounds, etc., can solve problems such as limited types

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] Example 1 - "Mill A"

[0057] Mill A is an integrated paper machine for the production of printing grade paper using recycled grade paper as furnish.

[0058] Deinked pulp (DIP) for newsprint is produced using a common dual loop RCF (Regenerated Fiber) unit.

[0059] Raw materials consisted of standard household quality ONP and OMG (old newsprint and magazine grade, respectively). The treatment temperature is 40-50°C, the water hardness is 10-30odH, and the pH is 7-9.

[0060] In the DIP unit, use NaOH (caustic soda), water glass (silicate) and H 2 o 2(peroxide) for ink detachment and to prevent ink redeposition and yellowing. In addition, sodium soap is added in the pre-flotation circuit and post-flotation circuit for ink removal. Due to the hardness of the water, the soap is at least partially converted to calcium soap. Soap was incorporated in an amount of 2-3 kg / ton (calculated as fatty acid per ton dry discharge from pulper / drum).

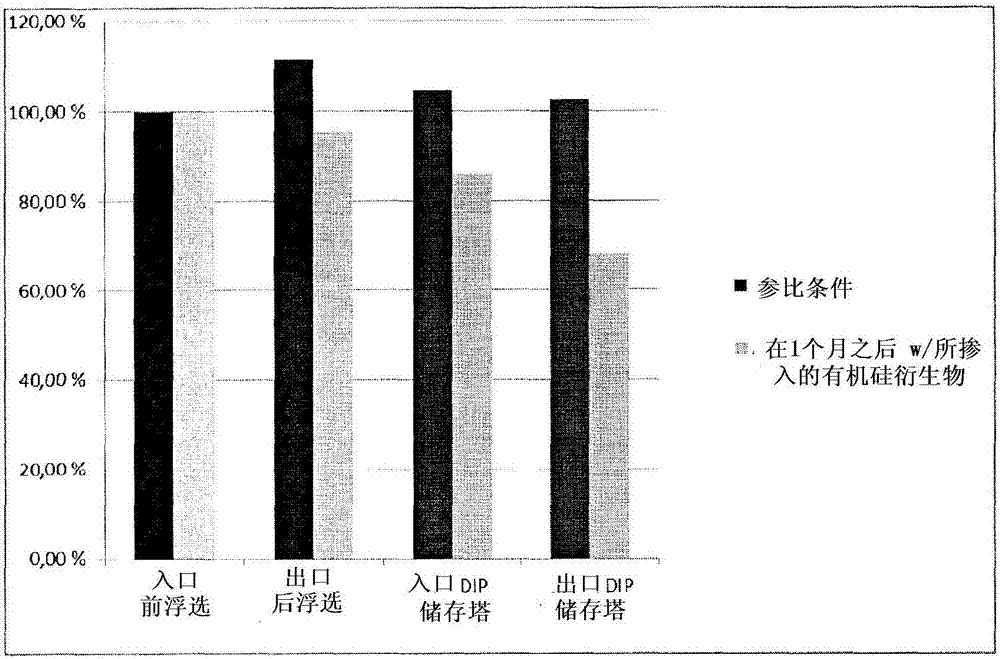

[0061] The amount of hy...

Embodiment 2

[0069] Example 2 - "Mill B"

[0070] Mill B is a dual loop RCF unit to produce DIP for newsprint production. The composition of ingredients included standard household quality ONP and OMG.

[0071] Again the same chemical mixture containing caustic, silicate and peroxide is used for ink stripping and to prevent ink redeposition and yellowing.

[0072] Again, in addition to this chemical mixture, sodium soaps that convert to calcium soaps due to water hardness are added for ink removal in the pre and post flotation circuits.

[0073] The treatment temperature is 45-50°C, the water hardness is 10-30odH, and the pH value is 7-9.

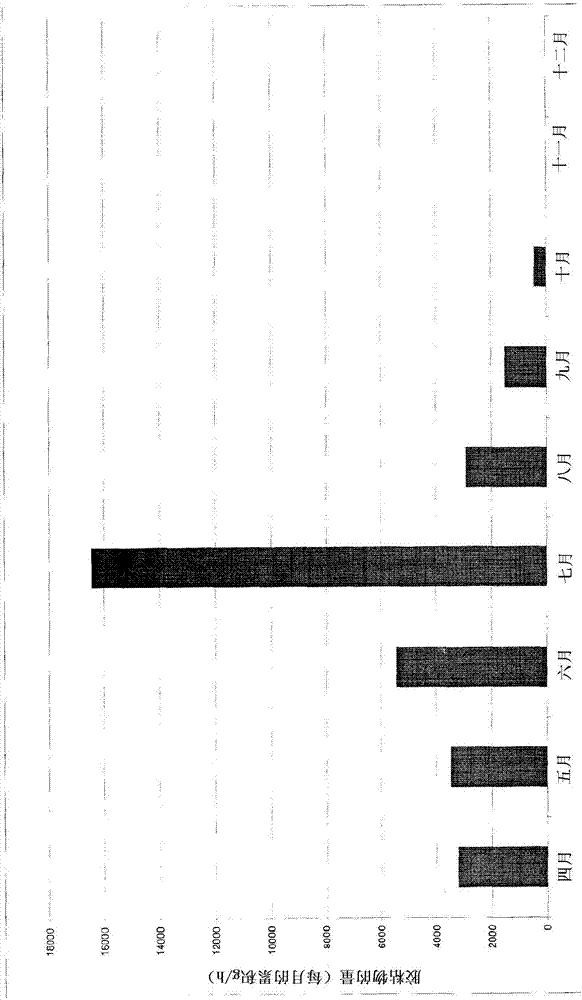

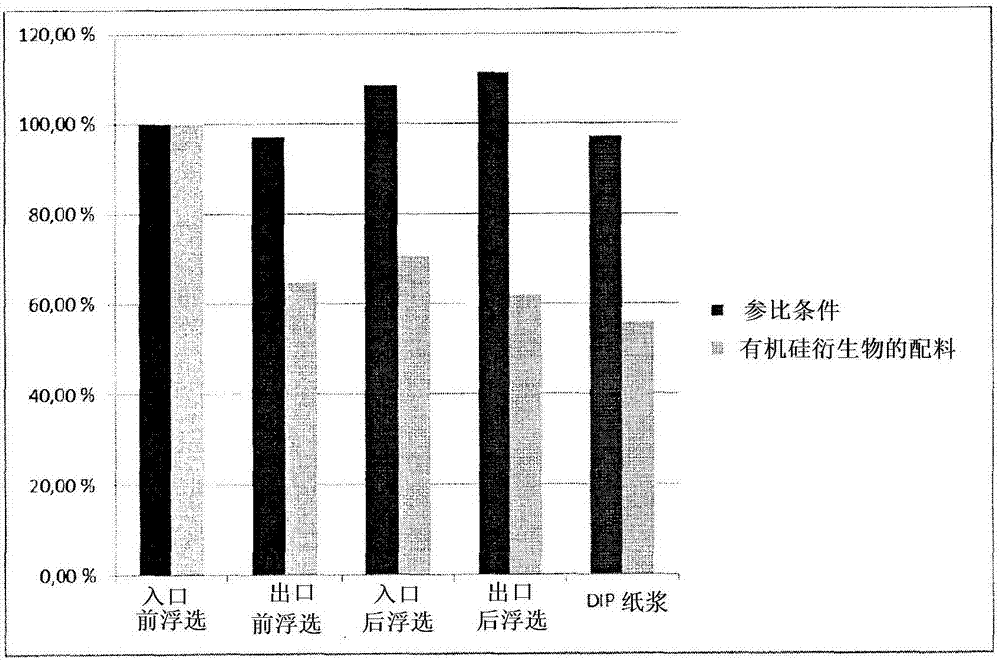

[0074] To assess the presence of sticky-forming deposits on surfaces in processing systems by studying the amount of hydrophobic micro-stickies present in RCF units and at various locations in the wet end of a paper machine by flow cytometry possibility.

[0075] During the reference period, 1.5 kg sodium soap / ton (as fatty acid) was added to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com