Ozone bleaching device

An ozone and central pipe technology is applied in pulp bleaching, preventing corrosion/sediment formation of pulping equipment, and papermaking. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

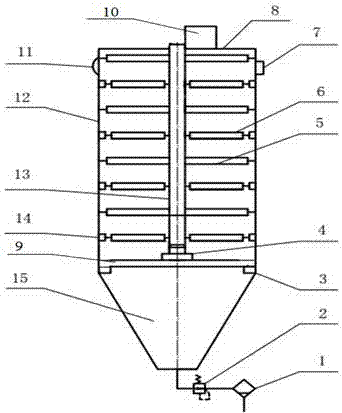

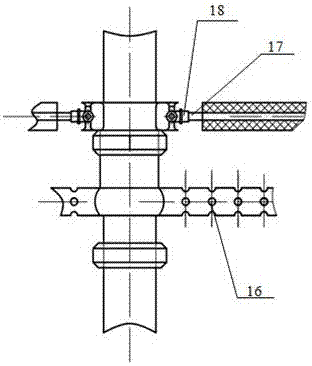

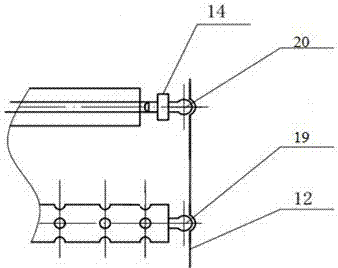

[0029] Embodiment 1: as Figure 1-5As shown, the ozone bleaching device of the present invention includes a slurry discharger 1, a pressure regulating valve 2, an annular bearing platform 3, a motor I4, a central pipe branch 5, a pulp-hanging omentum 6, a liquid level sensor 7, a constant pressure pump 10, an infrared moisture Instrument 11, box body 12, center pipe 13, motor II 14, slurry conical pool 15, universal coupling 18; the box body 12 includes a sealed box cover 8, a box bottom 9, and the box bottom 9 is provided with a leak hole. The diameter of the hole is 4 mm, and the annular bearing platform 3 is installed under the box bottom 9, and the slurry accumulation conical pool 15 is installed under the annular bearing platform 3. Regulating valve 2, motor I4 is installed above the box bottom 9, one end of the central tube 13 is connected to the output shaft of the motor I4, the motor I4 drives the central tube 13 to rotate, the other end of the central tube 13 protrude...

Embodiment 2

[0030] Embodiment 2: The device structure of this embodiment is the same as that of Embodiment 1. The difference is that the diameter of the 9 leakage holes at the bottom of the box is 2mm, and there are 6 layers of slurry-coating layers on the central tube 13, and each layer has 8 slurry-coating omentums, which have 6 layers. There are 16 central pipe branching layers in each layer. The diameter of the holes on the central pipe branching pipes 5 is 3cm, and the interval along the axis is 10cm. The diameter of lubricating ball I19 and lubricating ball II20 is 5cm. The vertical distance between the plasma omentum 6 is 15 / 24 of the 6 arc lengths of the slurry omentum.

Embodiment 3

[0031] Embodiment 3: The device structure of this embodiment is the same as that of Embodiment 1. The difference is that the diameter of the 9 leakage holes at the bottom of the box is 5mm, and there are 8 layers of slurry-coating layers on the central tube 13, and each layer has 12 slurry-coating omentums, which have 8 layers. The central tube is divided into layers, and each layer has 18 central tubes 5. The diameter of the holes on the central tube 5 is 2cm, and the distance along the axis is 8cm. The diameter of the lubricating ball I19 and the lubricating ball II20 is 4.5cm.

[0032] The slurry is pumped into the center pipe 13 with a certain pressure through the constant pressure pump 10, and discharged through the center pipe branch pipe 5. Because the pressure is constant, the pressure value of each center pipe branch pipe 5 can be made the same, and the slurry passes through the central pipe branch pipe 5. The hole 16 is discharged, evenly sprinkled on the slurry oment...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com