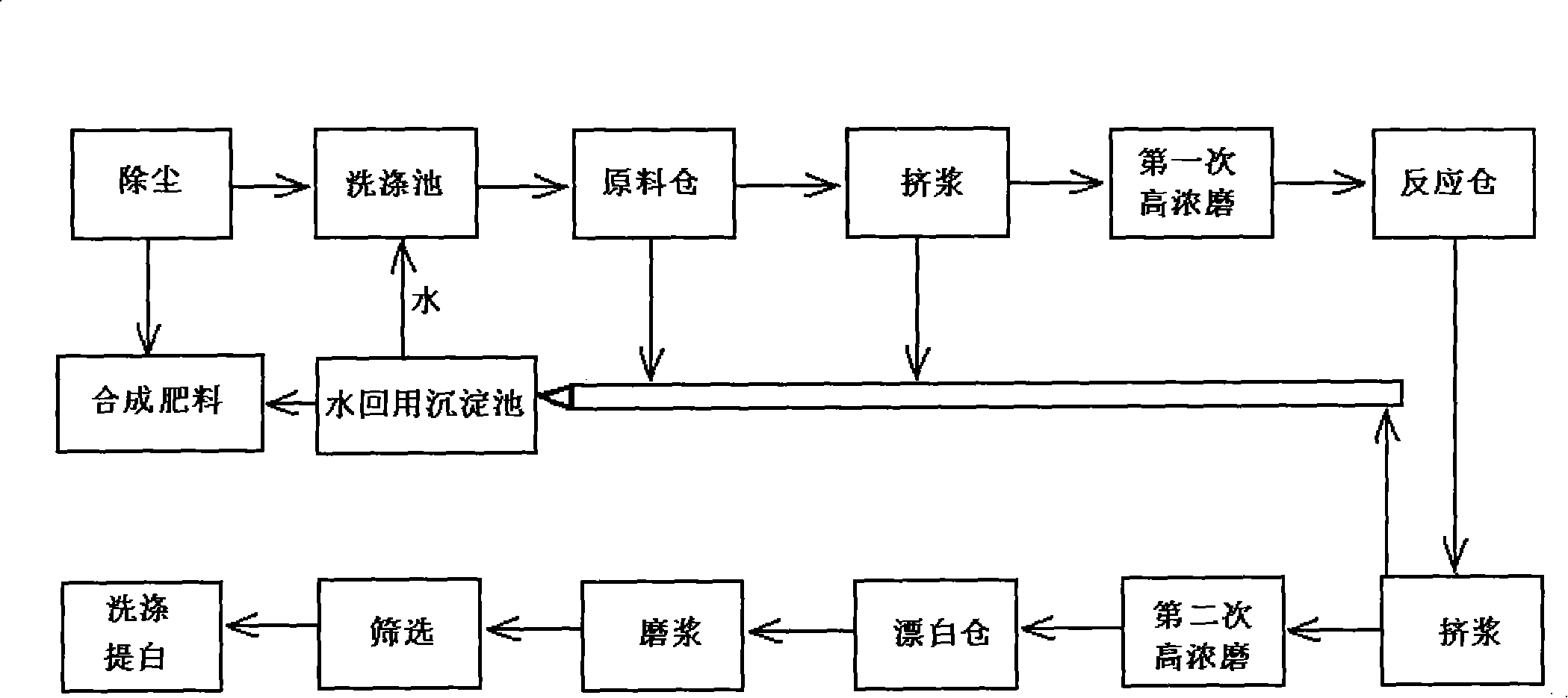

Clean pulping process

A clean pulping and process technology, applied in the continuous pulping process, pulping with inorganic alkali, pulp bleaching and other directions, can solve the problems of wheat straw waste, economic loss, pollution, etc. Simple effect of pulp process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0031] Embodiment: Taking cotton stalk pulping as an example:

[0032] (1) Cutting grass or crushing dust removal: remove dust from cotton stalk raw material impurities; use special crushing and dedusting equipment for cotton stalks, after crushing, the dust removal rate is high, which is beneficial to pulping production;

[0033] (2) Flying knife washing pool: Send the crushed and dedusted cotton stalks into the washing pool with a beater through a transmission belt, and soften the cotton stalk raw materials at room temperature; the flying knife washing pool is an oval pool A propeller is installed at one end of the pool to push the water in the pool to rotate, and a flying knife beating device is installed in the middle of the pool. The flying knife beating and washing is to soften the cotton stalk raw material, so that the cotton stalk raw material can be used in a short period of time. Saturated with water, remove surface impurities, and dissolve part of the pigment. The w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com