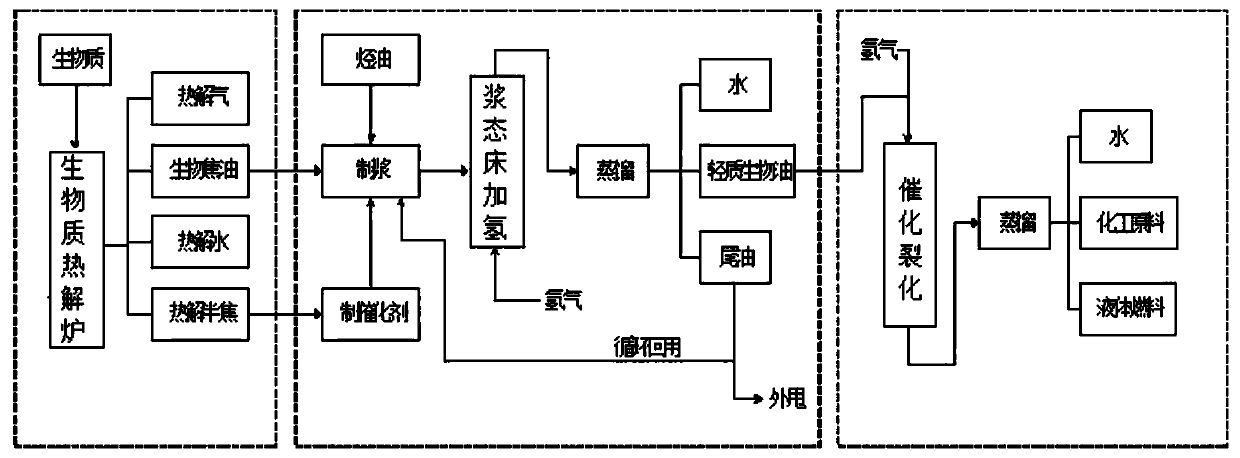

Method for preparing chemical raw materials and liquid fuels from biomass

A chemical raw material and liquid fuel technology, which is applied in the preparation of liquid hydrocarbon mixtures, petroleum industry, hydrogenation process, etc., can solve the problems of difficult separation, easy oxidative deterioration and polycondensation, poor stability of bio-pyrolysis tar, etc., to achieve The effect of good catalytic activity, high conversion rate and simple biomass pulping process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

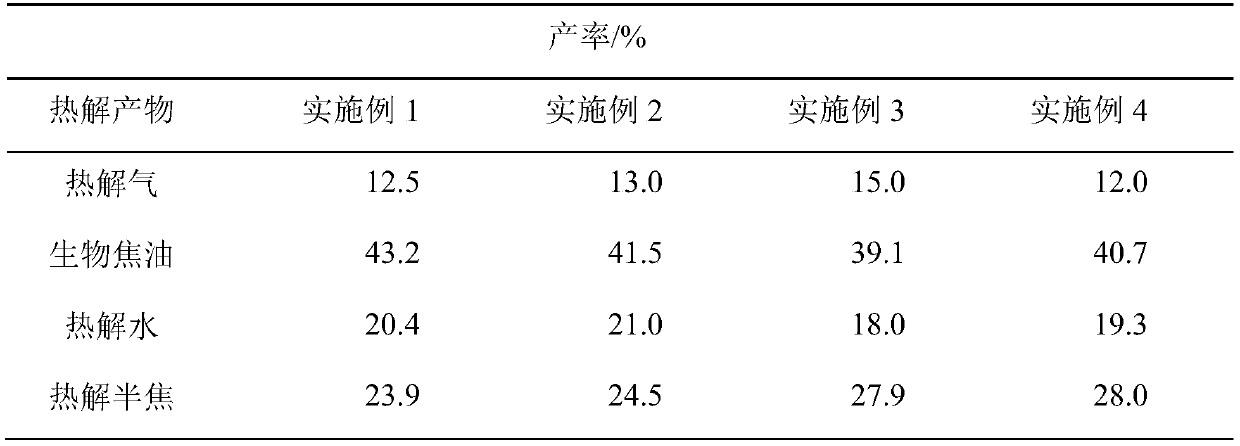

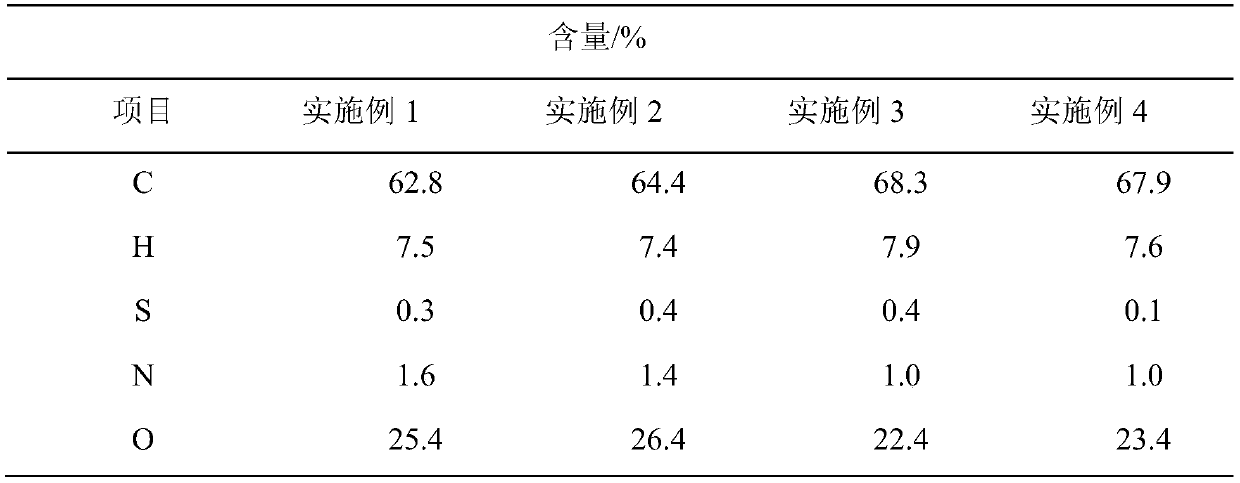

[0030] Step 1. Use straw as biomass raw material. After pre-drying and crushing the straw, enter the rotary cone pyrolysis reactor for pyrolysis reaction. The operating temperature of biomass pyrolysis is 500°C, and the heating rate is 500°C / min. Pyrolysis products including pyrolysis gas, bio-tar, pyrolysis water and pyrolysis semi-coke were obtained; the distribution of the obtained pyrolysis products is shown in Table 1. Among them, the elemental analysis of biotar is shown in Table 2.

[0031] Step 2. The pyrolysis semi-coke obtained in step 1 is used as a carrier to prepare the first catalyst, the pyrolysis semi-coke is pre-ground to 40-200 mesh, and iron oxyhydroxide is used as an active component to prepare a slurry bed hydrogenation catalyst. Wherein, the ratio of active components and pyrolysis semi-coke is 0.5:1, and it is ready for use;

[0032] Step 3, the biotar obtained in step 1, the first catalyst obtained in step 2, and the hydrocarbon oil are made into a slu...

Embodiment 2

[0036] Step 1. Use the waste wood residue as biomass raw material. After pre-drying and crushing the waste wood residue, enter the rotary kiln pyrolysis reactor for pyrolysis reaction. The operating temperature of biomass pyrolysis is 300°C, and the heating rate is 100 °C / min to obtain pyrolysis products including pyrolysis gas, bio-tar, pyrolysis water and pyrolysis semi-coke. The distribution of the pyrolysis products obtained is shown in Table 1. Among them, the elemental analysis of biotar is shown in Table 2.

[0037] Step 2. The pyrolysis semi-coke obtained in step 1 is used as a carrier to prepare the first catalyst, the pyrolysis semi-coke is pre-ground to 40-200 mesh, and iron oxyhydroxide is used as an active component to prepare a slurry bed hydrogenation catalyst. Wherein, the ratio of active components and pyrolysis semi-coke is 0.6:1, and it is ready for use;

[0038] Step 3, the biotar obtained in step 1, the first catalyst obtained in step 2, and the hydrocar...

Embodiment 3

[0042] Step 1. Use municipal waste as biomass raw material. After sorting the municipal waste, take the recyclable waste for pre-drying and crushing, and then enter the fluidized bed pyrolysis reactor for pyrolysis reaction. The operating temperature of biomass pyrolysis is 600 °C, the heating rate is 600 °C / min, and pyrolysis products including pyrolysis gas, bio-tar, pyrolysis water and pyrolysis semi-coke are obtained. The distribution of the pyrolysis products obtained is shown in Table 1. Among them, the elemental analysis of biotar is shown in Table 2.

[0043] Step 2. The pyrolysis semi-coke obtained in step 1 is used as a carrier to prepare the first catalyst, the pyrolysis semi-coke is pre-ground to 40-200 mesh, and iron oxyhydroxide is used as an active component to prepare a slurry bed hydrogenation catalyst. Wherein, the ratio of active components and pyrolysis semi-coke is 0.6:1, and it is ready for use;

[0044] Step 3, the biotar obtained in step 1, the first ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com