Method for loading fibers contained in a pulp suspension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

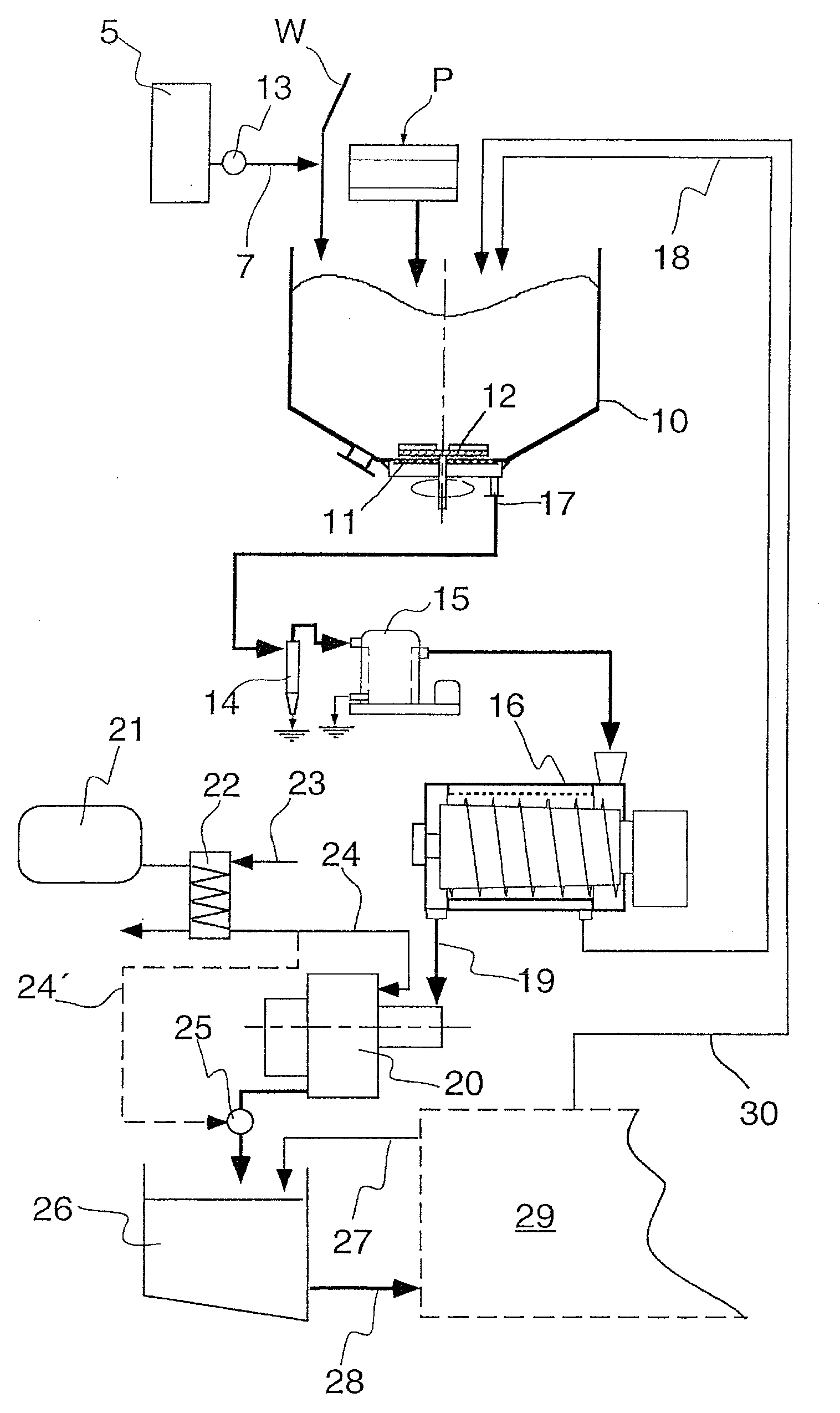

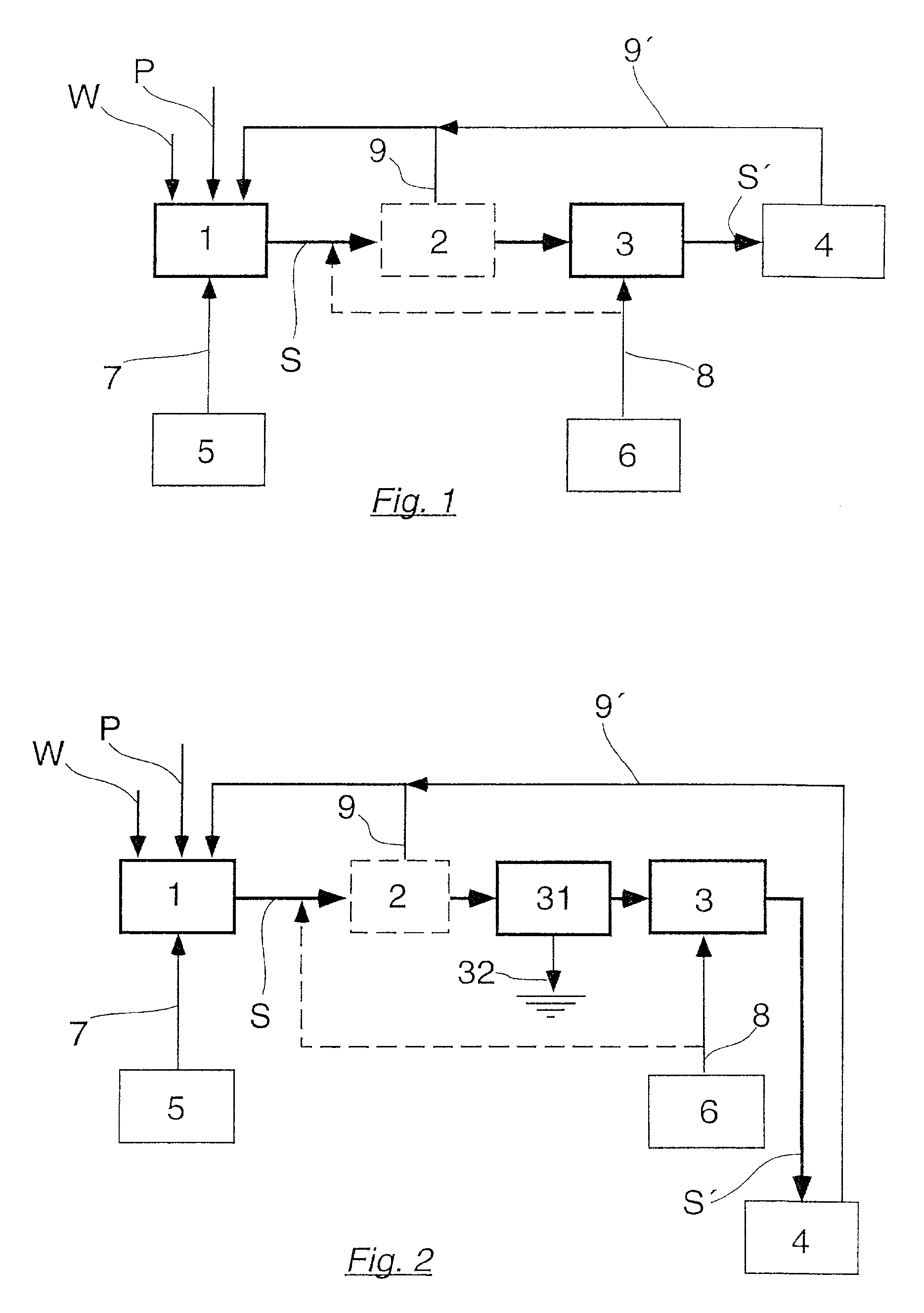

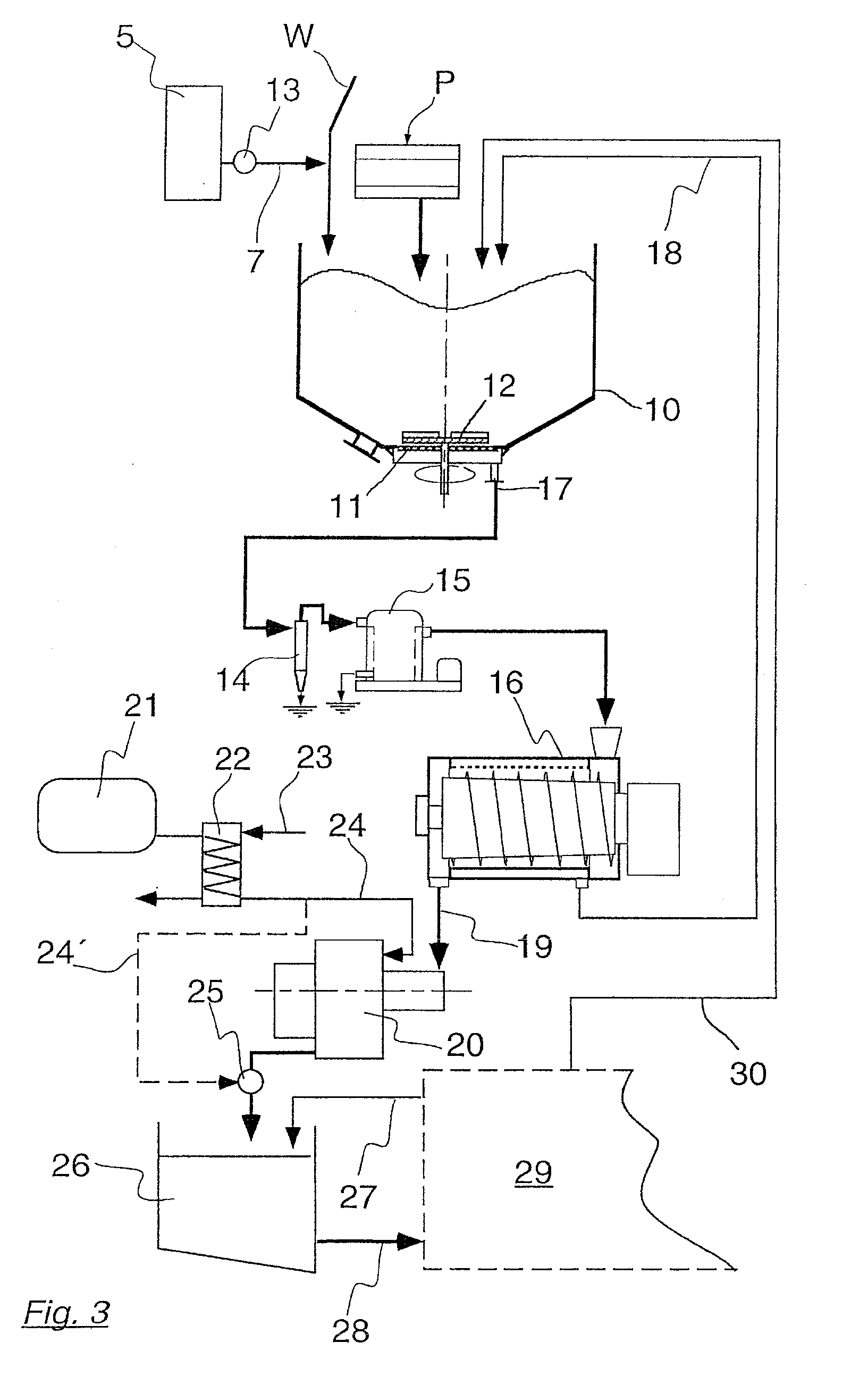

[0024]Referring now to the drawings, and more particularly to FIG. 1, which illustrates an embodiment of the present invention, the pulp P, which may be waste paper or alternatively, fresh chemical pulp, is processed in pulping operation 1. Therein, a pulp suspension S is produced by admixing water W with the aid of a mechanical working. The calcium hydroxide in this example is added as milk of lime 7 during the pulping operation, and is provided by slaking lime in the milk-of-lime production stage 5. Optionally, the pulp suspension S may be passed through a cleaning system, not shown here, in which heavy particles and plastics or other trash are removed. Whether this is necessary will depend predominantly on the quality of the raw material. A thickening operation 2 may then take place, but is not always necessary and, therefore, is shown in broken lines. Filtrate 9 from thickening operation 2 is used for pulping operation 1. The precipitation 3 of fine matter, in particular calcium...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com