Method for pulping and paper-making

A technology of pulping and papermaking, process, applied in the direction of papermaking, textile and papermaking, continuous pulping process, etc., can solve the problems of narrow application range, decline of soil fertility, and reduction of organic matter, so as to reduce transportation costs, low raw material costs, and reduce The effect of moisture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

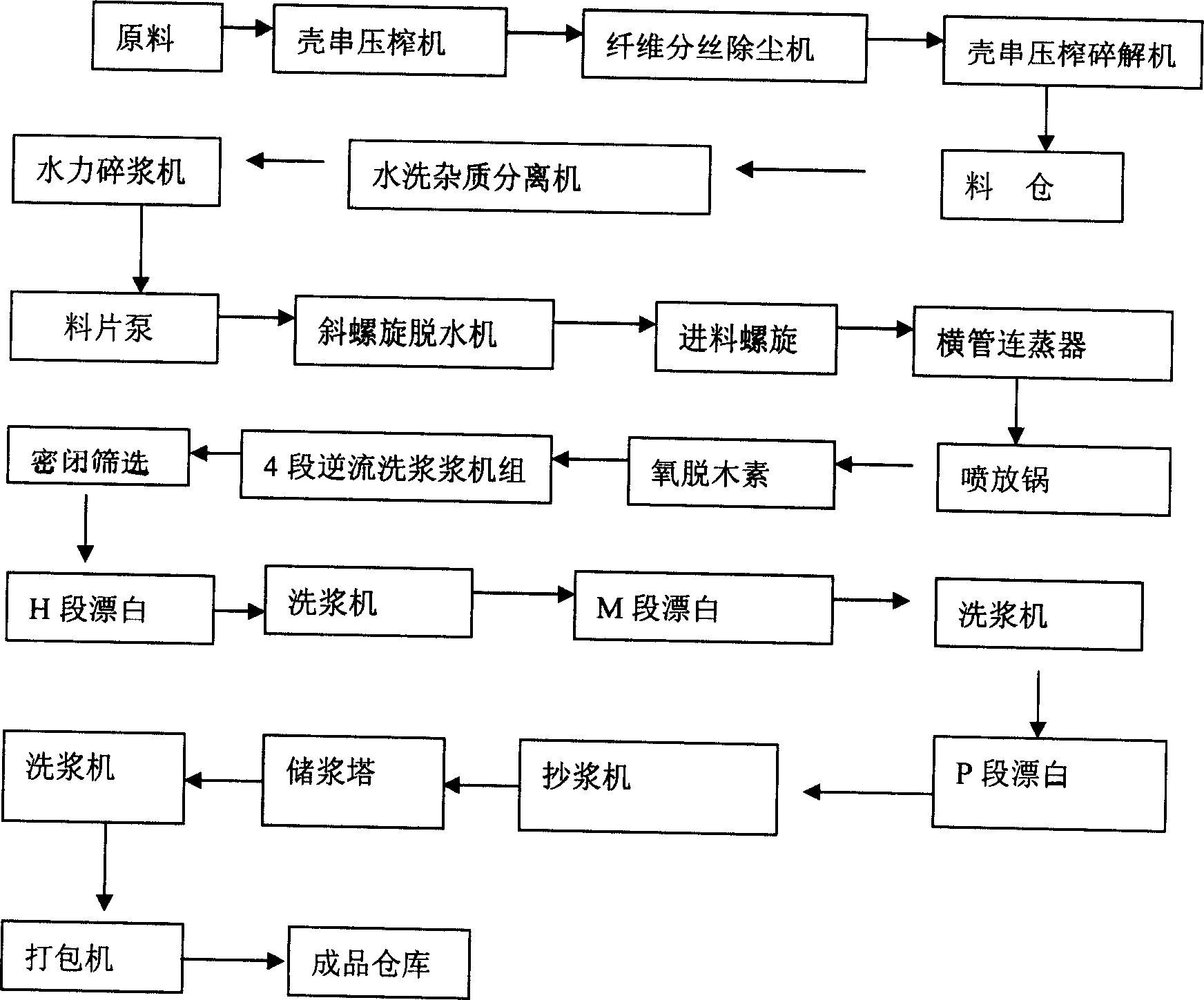

Image

Examples

Embodiment 1

[0018] The raw material that present embodiment just uses is: the withered leaf stem of coconut tree, palm tree, areca palm, banana tree and pineapple tree, the outer wrapping of tree stem, the stem that connects trunk and fruit, shell string and coconut tree and the husk of the fruit of the betel nut tree totaling 500 kg.

[0019] The above-mentioned raw materials are cut into sections, cleaned, and then transported to the raw material yard, and then the above-mentioned raw materials are analyzed in batches.

[0020] The following part of the present embodiment describes the preparation process of the present invention:

[0021] The raw materials after batch analysis are transported to the material preparation section of the pulping workshop by a belt conveyor. The raw materials are crushed and crushed by the shell string crushing machine, fiber separation and dedusting, and then crushed by the shell string crushing machine. Then it is washed and removed by the impurity sepa...

Embodiment 2

[0027] The raw material that present embodiment just uses is: the withered leaf stem of coconut tree, palm tree, areca palm, banana tree and pineapple tree, the outer wrapping of tree stem, the stem that connects trunk and fruit, shell string and coconut tree 1,000 kilograms in total and the shell of the fruit of the betel nut tree.

[0028] The above-mentioned raw materials are cut into sections, cleaned, and then transported to the raw material yard, and then the above-mentioned raw materials are analyzed in batches.

[0029] The following part of the present embodiment describes the preparation process of the present invention:

[0030] The raw materials after batch analysis are transported to the material preparation section of the pulping workshop by a belt conveyor. The raw materials are crushed and crushed by the shell string crushing machine, fiber separation and dedusting, and then crushed by the shell string crushing machine. Then it is washed and removed by the imp...

Embodiment 3

[0036] The raw material that present embodiment just uses is: the withered leaf stem of coconut tree, palm tree, areca palm, banana tree and pineapple tree, the outer wrapping of tree stem, the stem that connects trunk and fruit, shell string and coconut tree 1,000 kilograms in total and the shell of the fruit of the betel nut tree.

[0037] The above-mentioned raw materials are cut into sections, cleaned, and then transported to the raw material yard, and then the above-mentioned raw materials are analyzed in batches.

[0038] The following part of the present embodiment describes the preparation process of the present invention:

[0039] The raw materials after batch analysis are transported to the material preparation section of the pulping workshop by a belt conveyor. The raw materials are crushed and crushed by the shell string crushing machine, fiber separation and dedusting, and then crushed by the shell string crushing machine. Then it is washed and removed by the imp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com