Comprehensive straw utilization method

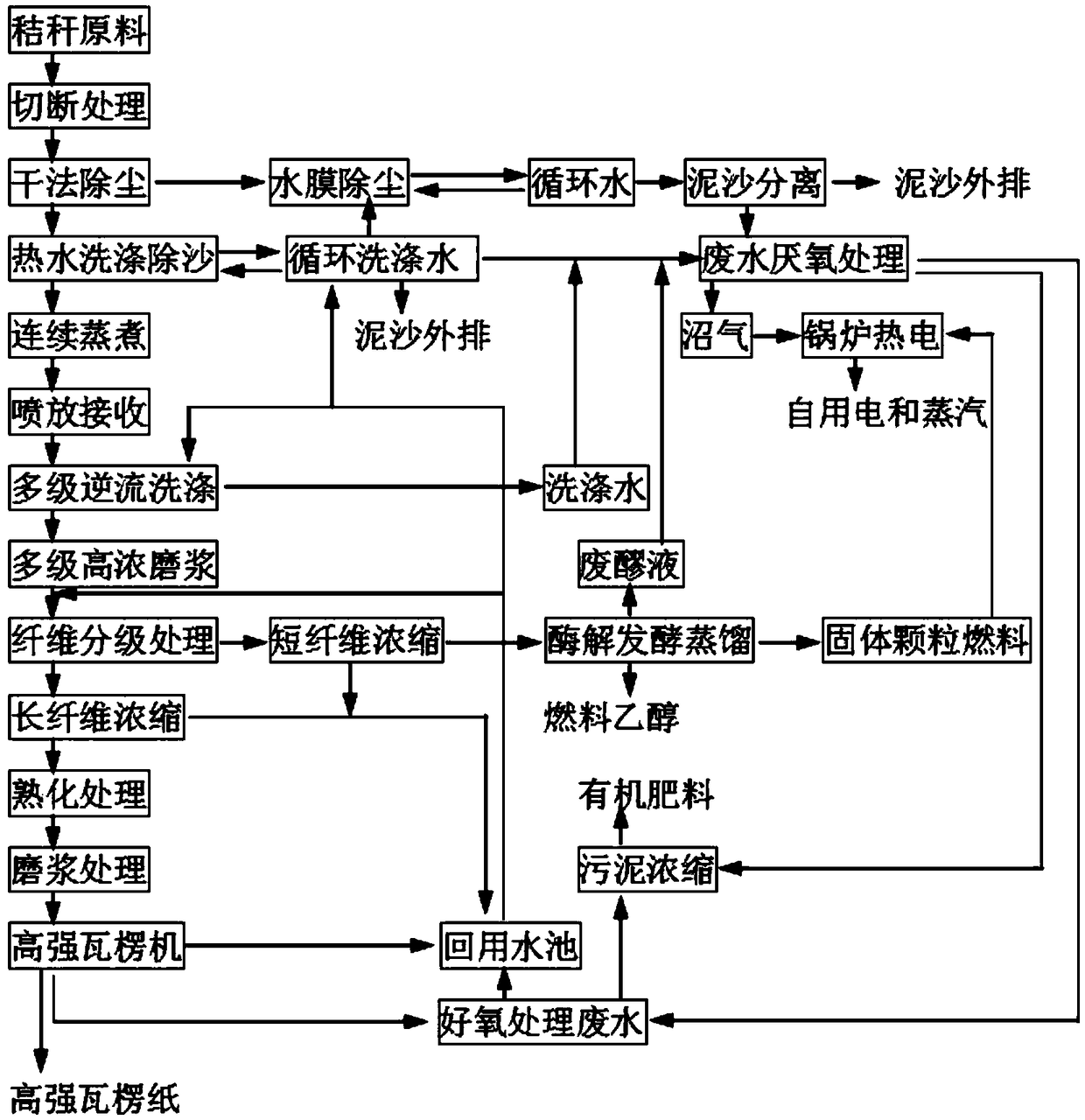

A straw and dry dust removal technology, applied in the direction of biochemical equipment and methods, pulp beating/refining method, bioreactor/fermenter combination, etc., can solve the problem of increasing washing water, increasing the amount of chemical additives, not having pulp etc., to achieve the effects of reducing steam and power consumption, protecting fiber length, and improving water filtration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071]The straw material is continuously sent to the straw cutting machine through the belt conveyor, the straw material is cut off, and then sent to the dust collector through the belt conveyor; the straw material is loosely turned in the roller dust collector, and the silt adhered to the material is screened out. Then it is sent to the washing and sand removal device through the belt conveyor. The cut length of the straw material is 30-50mm, and the qualified rate is 85%. The raised dust and debris are sucked into the water film dust removal system by the induced draft fan. Under the action of spray water at a temperature of 60°C, the sediment settles and is discharged, and the liquid part is filtered out to remove debris and recycled until the COD reaches 50mg / L, and the water is sent for anaerobic biogas production.

[0072] The dust-removed material is sent to the washing and desanding device, the washing time is 20min, the washing water temperature is 80°C, the washing ma...

Embodiment 2

[0081] The straw material is continuously sent to the straw cutting machine through the belt conveyor, the straw material is cut off, and then sent to the dust collector through the belt conveyor; the straw material is loosely turned in the roller dust collector, and the silt adhered to the material is screened out. Then it is sent to the washing and sand removal device through the belt conveyor. The cut length of the straw material is 30-50mm, and the qualified rate is 90%. The raised dust and debris are sucked into the water film dust removal system by the induced draft fan. Under the action of spraying water at a temperature of 65°C, the sediment settles and is discharged, and the liquid part is filtered out to remove debris and recycled until the COD reaches 55mg / L, and the water is sent for anaerobic biogas production.

[0082] The dust-removed material is sent to the washing and desanding device, the washing time is 15min, the washing water temperature is 80°C, the washin...

Embodiment 3

[0091] The straw material is continuously sent to the straw cutting machine through the belt conveyor, the straw material is cut off, and then sent to the dust collector through the belt conveyor; the straw material is loosely turned in the roller dust collector, and the silt adhered to the material is screened out. Then it is sent to the washing and sand removal device through the belt conveyor. The cut length of the straw material is 30-50mm, and the qualified rate is 88%. The raised dust and debris are sucked into the water film dust removal system by the induced draft fan. Under the action of spraying water at a temperature of 55°C, the sediment settles and is discharged, and the liquid part is filtered out to remove debris and recycled until the COD reaches 53mg / L, and the water is sent for anaerobic biogas production.

[0092] The dust-removed material is sent to the washing and desanding device, the washing time is 10min, the washing water temperature is 80°C, the washin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com