Aldehyde and ketone inhibitor for alkaline washing tower of ethylene unit

An ethylene device and inhibitor technology, applied in the fields of hydrocarbons, chemical instruments and methods, organic chemistry, etc., can solve the limitations of the rapid dispersion effect of butter polymers, and do not mention the dispersion of polymers, etc., to achieve inhibition Scale generation, reduce equipment blockage, and prolong the effect of operating cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A kind of aldehyde and ketone inhibitor is prepared by the method comprising the following steps:

[0040] Add 180g of N-phenyl-α-naphthylamine, 200g of 2-mercaptothiadiazole, 150g of diethylaminoethanol, 180g of polysuccinimide, and 290g of deionized water into the container, and heat up while stirring. Stir at constant temperature after reaching 40°C, mix evenly, and filter to obtain the inhibitor product.

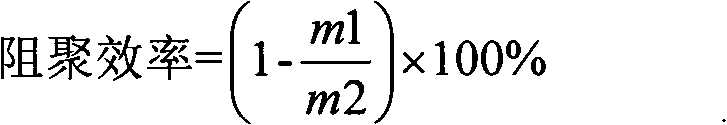

[0041] The aldehyde and ketone inhibitor in Example 1 is applied to the ethylene alkali washing tower simulation device, the cracking raw material is naphtha, the total yield of ethylene, propylene, and butadiene in the cracking gas is slightly 48.7%, and the sodium hydroxide in the alkali washing tower The concentration of the inhibitor is 7.65%, and the inhibitor is added to the circulating lye at one time, and the addition amount is 50ppm. The device runs continuously for 2 hours, calculates the weight of butter in the lye, and compares it with the amount of bu...

Embodiment 2

[0047] A kind of aldehyde and ketone inhibitor is prepared by the method comprising the following steps:

[0048] Add 100g 2,6-di-tert-butyl-p-cresol, 100g N,N-dialkylaminomethylenebenzenetriazole, 150g ethyleneamine, 100g monosuccinimide, and 550g deionized water to In the container, the temperature was raised while stirring, and the temperature was raised to 40° C., then stirred at a constant temperature, and after mixing evenly, the product was obtained by filtration.

[0049] Others are with embodiment 1.

Embodiment 3

[0051] A kind of aldehyde and ketone inhibitor is prepared by the method comprising the following steps:

[0052] 250g 2,6-di-tert-butylphenol, 200g 2-mercaptothiadiazole, 200g diethanolamine, 200g macromolecular succinimide, 150g deionized water are added to the container, and the temperature is raised while stirring, and the temperature is raised to Stir at a constant temperature after 40°C, mix evenly, and filter to obtain the product.

[0053] Others are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com