Rotating disc type dynamic membrane separating assembly

A technology of separation components and dynamic membranes, applied in semi-permeable membrane separation, membrane technology, chemical instruments and methods, etc., can solve the problem of affecting membrane permeation flux and mass transfer process, strict requirements for material and liquid pretreatment, and difficult flow paths. Cleaning and other issues to achieve the effect of extending the cleaning and maintenance cycle, reducing membrane pollution, and reducing requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

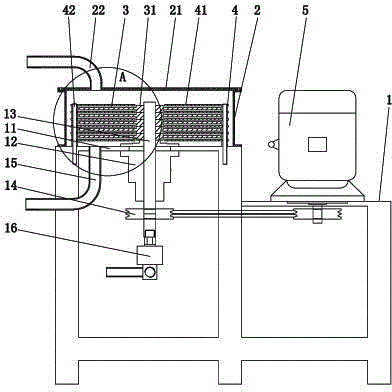

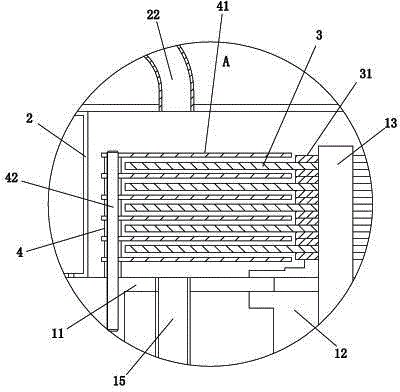

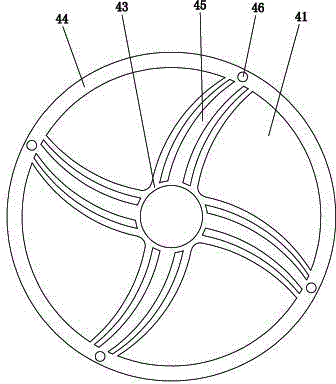

[0046] as attached Figure 1 As shown, the rotating disc dynamic membrane separation module of the present invention includes a frame, a filter disc, a rotating hollow shaft, a motor, a bearing seat, a motor bottom plate, a rotating flow baffle, a dynamic sealing device, an outer cylinder, a cover plate, a rotary joint, etc. composition. The filter disc is installed in a closed cylinder, which has a feed port (material) and a discharge port (concentrate), a 0.08μm filter membrane is installed on the filter disc, and 5 The disc filter disc rotates at a certain speed, and the permeate is discharged from the rotating hollow shaft through the rotary joint. The material is commercially available soybeans. Soybeans are soaked for 17 hours and crushed with a special soymilk machine for restaurants, and filtered through a 100-mesh filter (the soymilk machine comes with it) to obtain the filtered raw material. The raw material obtained after filtration contains soybean starch, fiber...

Embodiment 2

[0048] The structure of the rotary disc dynamic membrane separation module is the same as that of Example 1, and a 0.1 μm microfiltration membrane is installed on the filter disc. The material is wine foot mud from a certain vat, which has a relatively large solid content and viscosity. The permeate is clear and meets the owner's requirements for finished wine. No pre-filtering. During the nearly 7 hours of membrane separation, the permeate flow rate was always kept near Q=X L / ㎡*h. The pressure in the experiment was provided by a centrifugal pump to circulate the material back. The experiment ended because the centrifugal pump was having a hard time pushing the material back through the cycle. The concentration at the end of the experiment was not measured due to limited experimental conditions. The maximum temperature of the material rises by 3°C. There is no difference in the data measured by the two sets of prototypes.

Embodiment 3

[0050] The structure of the rotary disc dynamic membrane separation module is the same as that of Example 1, and a 0.1 μm microfiltration membrane is installed on the filter disc. The material is river water (river water is extracted directly from a river). 0.1μm microfiltration membrane direct filtration. The permeate is very clear, and a bamboo basket is set at the water inlet of the centrifugal pump to block large particles without flocculants. During the nearly 6 hours of membrane separation, the flow rate of permeate was always kept near Q=X L / ㎡*h. The pressure in the experiment was provided by a centrifugal pump. There is no reflux of the material and no change in the temperature of the material. The concentrated water is retained by the microfiltration membrane and discharged directly. Only one set of prototypes was used in this experiment.

[0051] Through this experiment we can get the following conclusions:

[0052] 1. The experiments in the above examples show...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com