Extraction agent composition, application thereof and method for recycling active component in solution

An active component and extractant technology, which is applied in the field of extractant composition and its application and recovery of active components in solution, can solve the problems of complex process, narrow application range, inconsistent vanadium state, etc., and achieves simple equipment and process, Wide application range and high adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

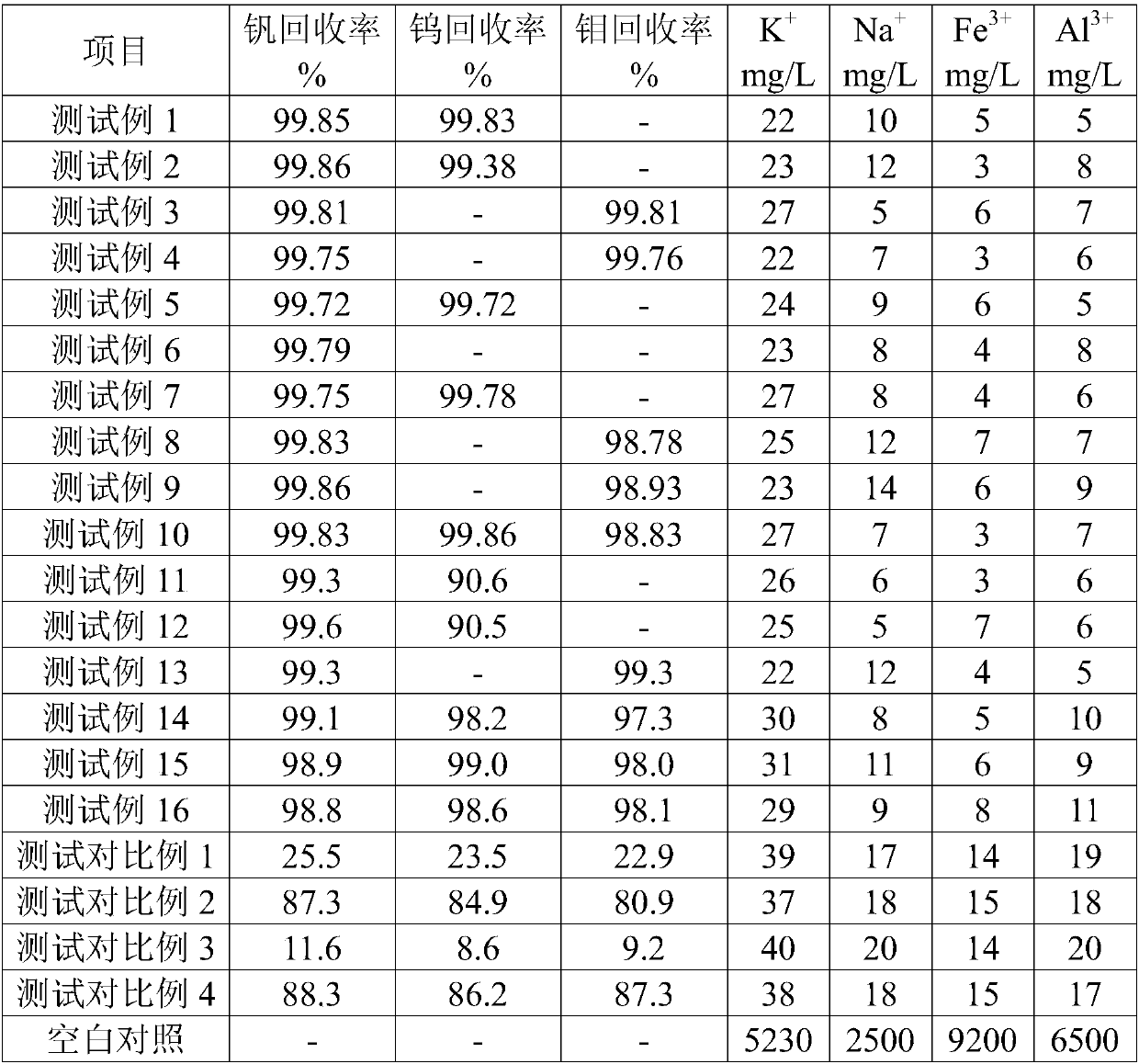

Embodiment 1

[0039] This embodiment is used to illustrate that the present invention provides extractant and the method for active component in recovery solution

[0040] The denitrification catalyst deactivation active supplement liquid that certain regeneration plant provides, its main component is 0.7% by weight ammonium metavanadate (in V 2 o 5 In terms of), 1.3% by weight of ammonium metatungstate (in terms of WO 3 meter), the pH is 8.5.

[0041] ① Discharge the exhausted active supplement solution into the sedimentation tank for natural settlement for 12 hours;

[0042] ②Filter the supernatant of the naturally settled active replenishing liquid and discharge it into the extraction and separation tank with high-pressure air stirring function, and add dilute sulfuric acid to adjust the pH to 4.5;

[0043] 3. Add extractant in the separation tank, the extractant composition is 5% by weight of N1923, 5% by weight of tributyl phosphate (TBP), 5% by weight of 2-octanol and 85% by weight...

Embodiment 2

[0049] This embodiment is used to illustrate that the present invention provides extractant and the method for active component in recovery solution

[0050] The denitrification catalyst deactivation active supplement liquid that certain regeneration plant provides, its main component is 1.2% by weight ammonium metavanadate (in V 2 o 5 In terms of), 2.1% by weight of ammonium metatungstate (in terms of WO 3 meter), the pH is 8.5.

[0051] ②The exhausted active replenishment solution is discharged into the sedimentation tank for natural settlement for 10 hours;

[0052] ②Filtrate the supernatant of the naturally settled active replenishing liquid and discharge it into the extraction and separation tank with high-pressure air stirring function, and add dilute hydrochloric acid to adjust the pH to 4.0;

[0053] 3. Add extractant in the separation tank, the extractant composition is 10% by weight N1923, 10% by weight tributyl phosphate (TBP), 10% by weight 2-octanol and 70% by ...

Embodiment 3

[0059] This embodiment is used to illustrate that the present invention provides extractant and the method for active component in recovery solution

[0060] The denitrification catalyst failure active supplement liquid that certain regenerating plant provides, its main component is 0.8% by weight ammonium metavanadate (in V 2 o 5 ), 1.0% by weight ammonium heptamolybdate (as MoO 3 meter), the pH is 8.3.

[0061] ① Discharge the exhausted active supplement solution into the sedimentation tank for natural settlement for 8 hours;

[0062] ②Filtrate the supernatant liquid of the naturally settled active replenishing liquid and discharge it into the extraction and separation tank with high-pressure air stirring function, and add dilute sulfuric acid to adjust the pH to 3.5;

[0063] 3. Add extractant in the separation tank, the extractant composition is 10% by weight N1923, 10% by weight tributyl phosphate (TBP), 10% by weight 2-octanol and 70% by weight sulfonated kerosene, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com