Horizontal flow precipitation separation device

A technology of sedimentation separation and horizontal flow, applied in the sedimentation tank and other directions, can solve the problems of complex structure of sedimentation separation device, easy to produce disturbance, easy to block the sludge discharge port, etc., to achieve fast and effective sedimentation effect, avoid disturbance effect, and ensure sedimentation speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

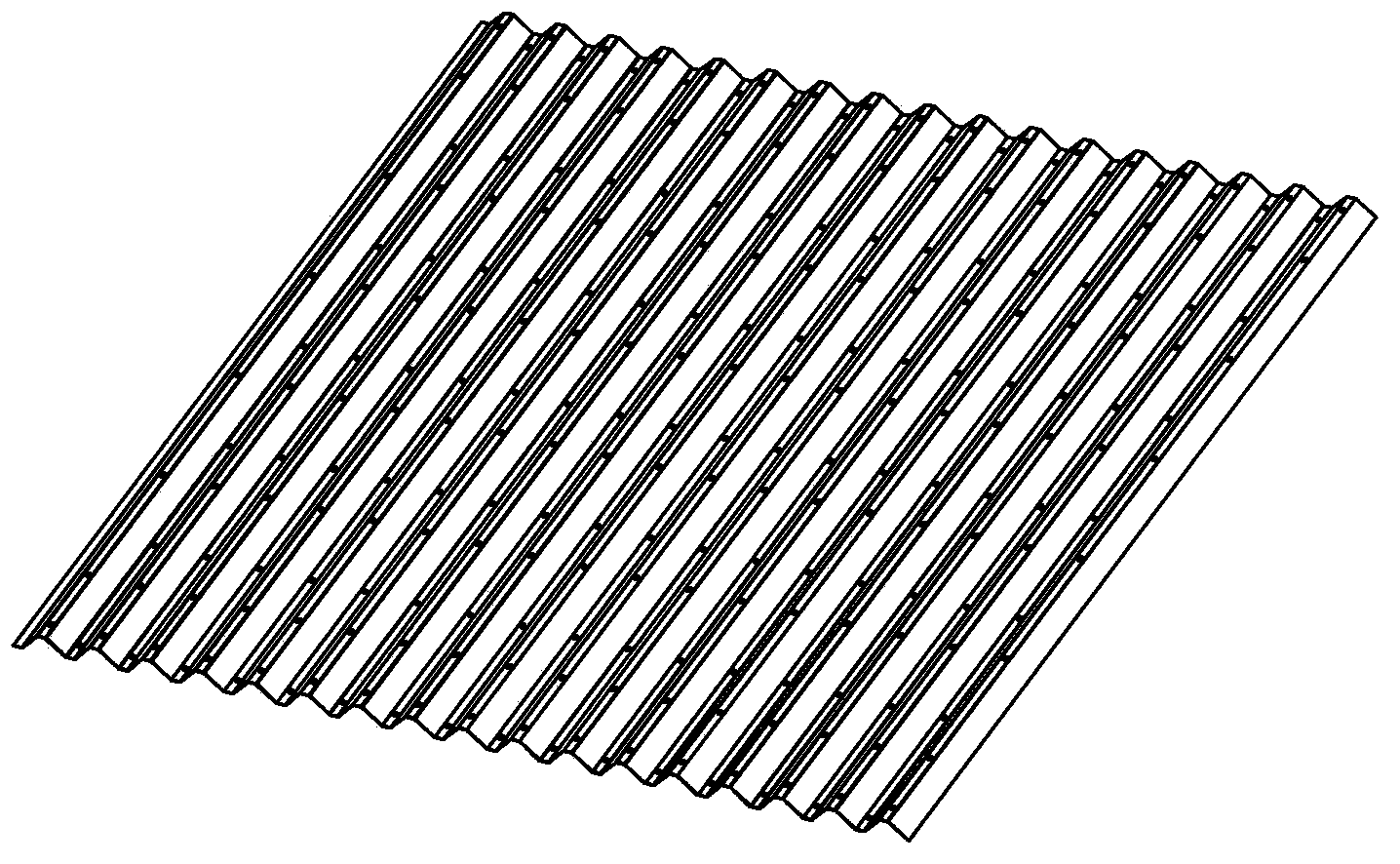

[0028] like Figure 1 to Figure 5 As shown, the horizontal flow sedimentation separation device is installed in the sedimentation tank 12, which includes:

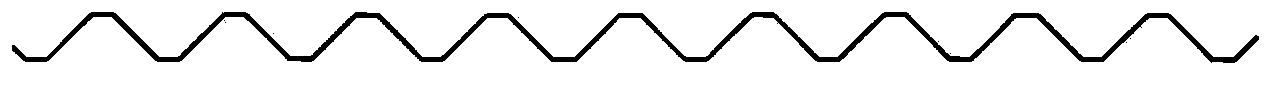

[0029] There are multiple corrugated plates 1, and these corrugated plates are arranged vertically relative to the horizontal plane, and the cross-section of the corrugated plates has a trapezoidal wave structure. The trapezoidal wave in this embodiment is an isosceles trapezoid, and the included angle α between the two waists and the corresponding valley bottom is 45°, and the width of the valley bottom is 1 cm. The width of the valley bottom can also select other sizes according to needs, usually Between 0.5 and 2 cm. The length of the two waists is 3 centimeters; the length of the waist can also be selected for other sizes as required, such as 2 to 3.5 centimeters.

[0030] In this embodiment, the surface of each corrugated pipe has a hydrophobic layer, thereby effectively reducing the resistance of the surface of the...

Embodiment 2

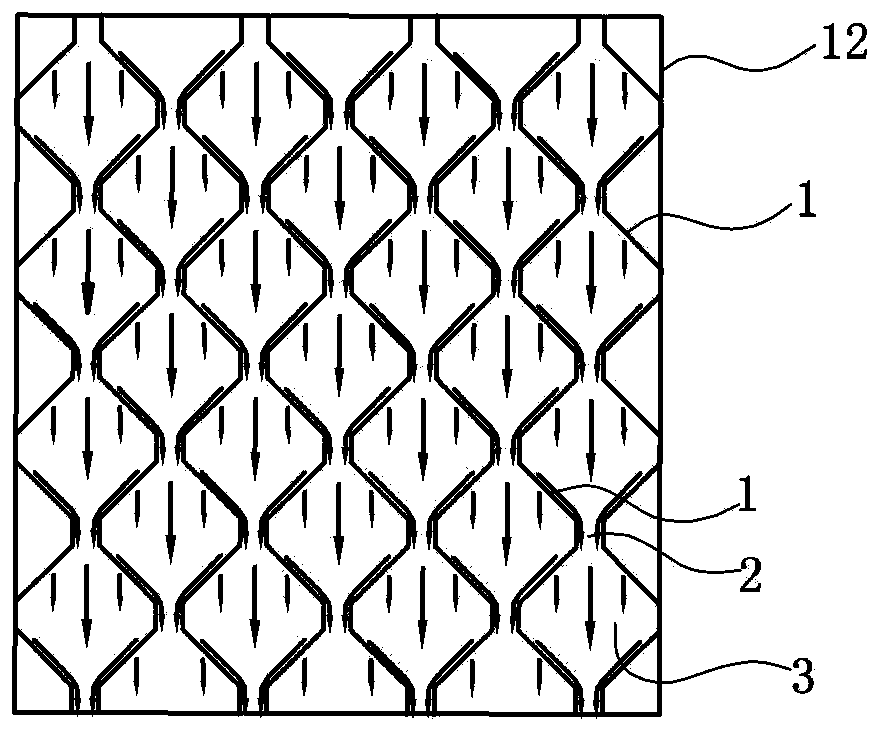

[0037] like Figure 6 to Figure 8 As shown, the horizontal flow sedimentation separation device includes:

[0038] There are multiple corrugated plates 1, and these corrugated plates are arranged vertically relative to the horizontal plane, and the cross-section of the corrugated plates has a trapezoidal wave structure. The trapezoidal wave in this embodiment is an isosceles trapezoid, and the included angle α between the two waists and the corresponding valley bottom is 45°, and the width of the valley bottom is 1 cm. The width of the valley bottom can also select other sizes according to needs, usually Between 0.5 and 2 cm. The length of the two waists is 3 centimeters; the length of the waist can also be selected for other sizes as required, such as 2 to 3.5 centimeters.

[0039] In this embodiment, the surface of each corrugated pipe has a hydrophobic layer, thereby effectively reducing the resistance of the surface of the corrugated plate to the sediment, and speeding u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com