Iron and steel complex comprehensive wastewater treatment device and process

A technology for comprehensive wastewater and combined enterprises, which is applied in the field of treatment devices and comprehensive wastewater treatment devices for iron and steel complexes, can solve the problems of increased equipment and operating costs, complex components, and failure to meet the economic requirements of wastewater treatment, and achieves energy consumption and operation. Low cost, simplified treatment process, high volume load effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073] A comprehensive wastewater treatment device for an iron and steel complex, the device includes a coagulation unit, a denitrification biofilter, a nitrification biofilter, a filter unit and an ozone catalytic oxidation unit connected in sequence; the coagulation unit is a mixing-flocculation- Sedimentation tank, the filter material in the denitrification biofilter is volcanic rock, the filter material in the nitrification biofilter is modified ceramsite and coke, the filter unit is an atmospheric filter, and the atmospheric filter The filter medium in the pool is quartz sand, the ozone catalytic oxidation unit is an ozone reactor and an ozone generator supplying ozone to the ozone reactor, and a catalyst is placed in the ozone reactor.

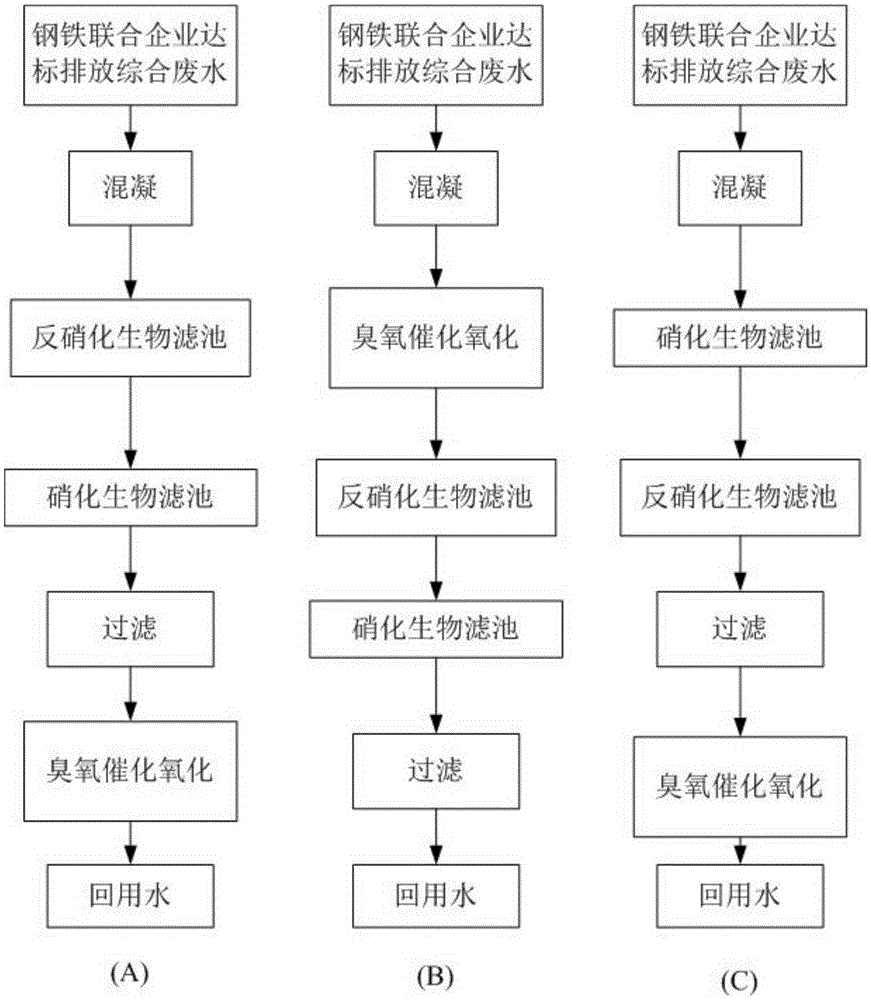

[0074] The process of using the above-mentioned device to treat wastewater such as figure 1 As shown in (A), the process includes the following steps: the wastewater to be treated first enters the coagulation unit, and coagulation agents...

Embodiment 2

[0080] A comprehensive wastewater treatment device for an iron and steel complex, the device includes a coagulation unit, an ozone catalytic oxidation unit, a denitrification biofilter, a nitrification biofilter and a filter unit connected in sequence; the coagulation unit is a high-density sedimentation tank , the filter material in the denitrification biofilter is volcanic rock and coke, the filter material in the nitrification biofilter is volcanic rock, modified ceramsite and coke, the filter unit is a multimedia filter, and the poly The filter medium in the medium filter is a combination of pebbles, quartz sand and anthracite, and the ozone catalytic oxidation unit is an ozone reactor and an ozone generator that supplies ozone to the ozone reactor, and a catalyst is placed in the ozone reactor.

[0081] Utilize the second process to treat wastewater, such as figure 1 As shown in (B), the process includes the following steps: the waste water to be treated first enters the ...

Embodiment 3

[0087] A comprehensive wastewater treatment device for an iron and steel complex, the device includes a coagulation unit, a nitrification biological filter, a denitrification biological filter, a filter unit and an ozone catalytic oxidation unit connected in sequence; the coagulation unit is a mechanically stirred clarifier , the filter material in the denitrification biofilter is modified ceramsite, the filter material in the nitrification biofilter is coke, the filter unit is an atmospheric filter, and the filter in the atmospheric filter The medium is a combination of pebbles, quartz sand and anthracite, and the ozone catalytic oxidation unit is an ozone reactor and an ozone generator that supplies ozone to the ozone reactor, and a catalyst is placed in the ozone reactor.

[0088] The process of using the above-mentioned device to treat wastewater such as figure 1 As shown in (C), the process includes the following steps: the waste water to be treated first enters the coagu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com