Photo-Fenton catalyst and preparation method thereof and application thereof in water treatment

A catalyst and solvent technology, which is applied in the direction of light water/sewage treatment, oxidized water/sewage treatment, water/sewage treatment, etc., can solve the problems of reducing the degradation efficiency of organic matter, reducing surface active sites, and prone to agglomeration, etc., to achieve improved catalysis performance, improved photogenerated charge separation and transport, and faster conversion effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] (1) Add 30g of urea to the crucible, add the crucible cover, and heat at 2.5°C min -1 Heating at a rate of 550°C for 4h, adding the resulting product back into the crucible without the crucible lid, and then heating at 2°C min -1 The rate is heated to 500°C for 2h to obtain g-C 3 N 4 Nanosheets;

[0042] (2) the g-C obtained in step (1) 3 N 4 The nanosheets were added to the ethanol solution at a concentration of 2.0 g L -1 , sonicate until the dispersion is uniform, add ferric nitrate and ammonium bicarbonate to the dispersion in turn, so that the concentrations are 1.0 and 3.0mol L -1 , stirred for 10 h, separated by filtration, washed with deionized water and dried, and the dried product was heated at 2°C min -1 The rate is heated to 350 ° C for 2 h to obtain g-C 3 N 4 / Fe 2 o 3 Complex.

[0043] Characterization tests:

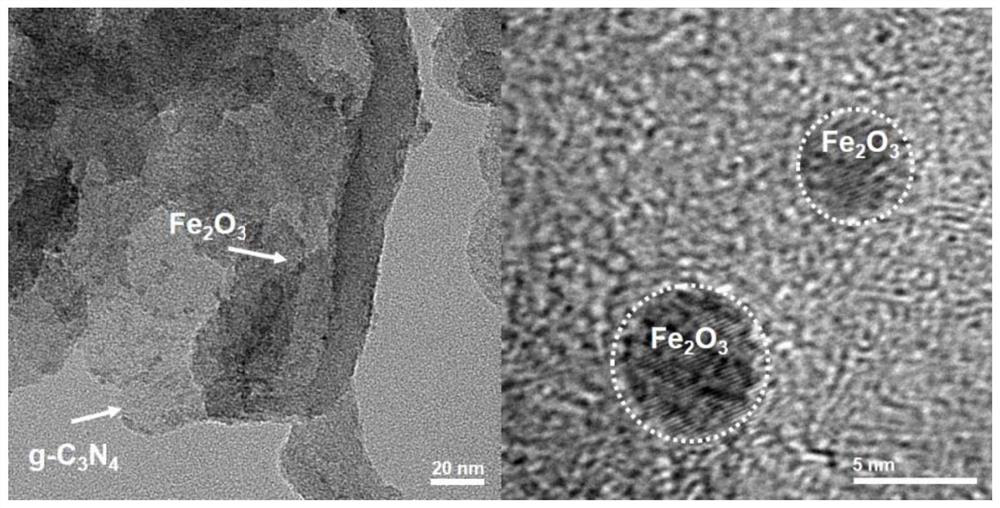

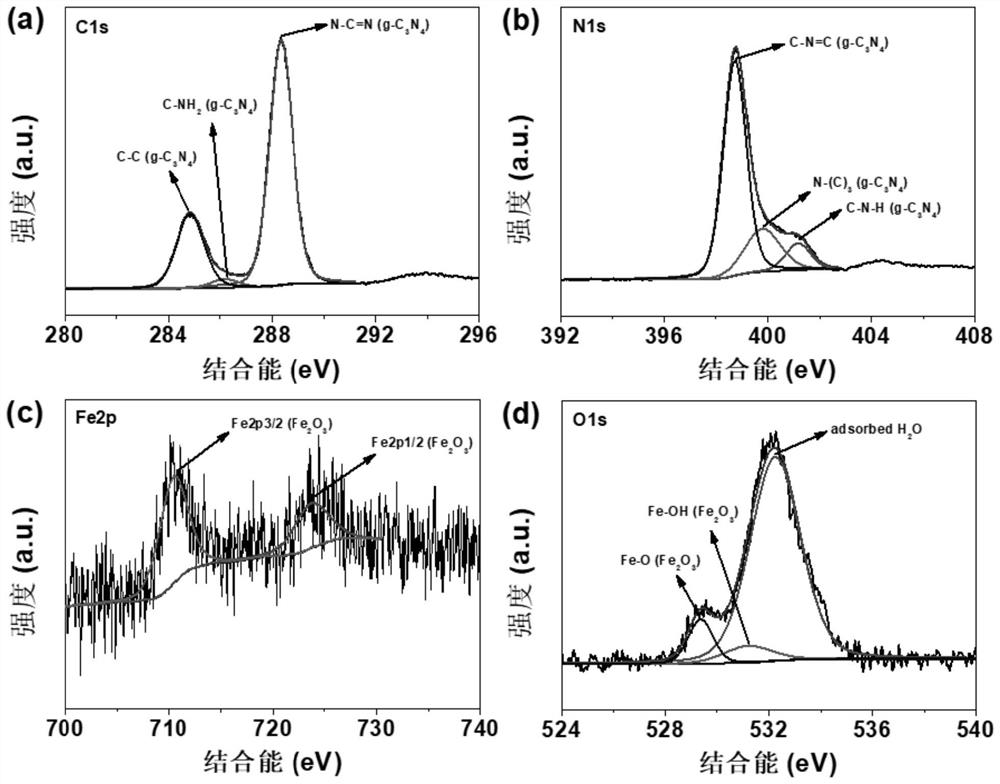

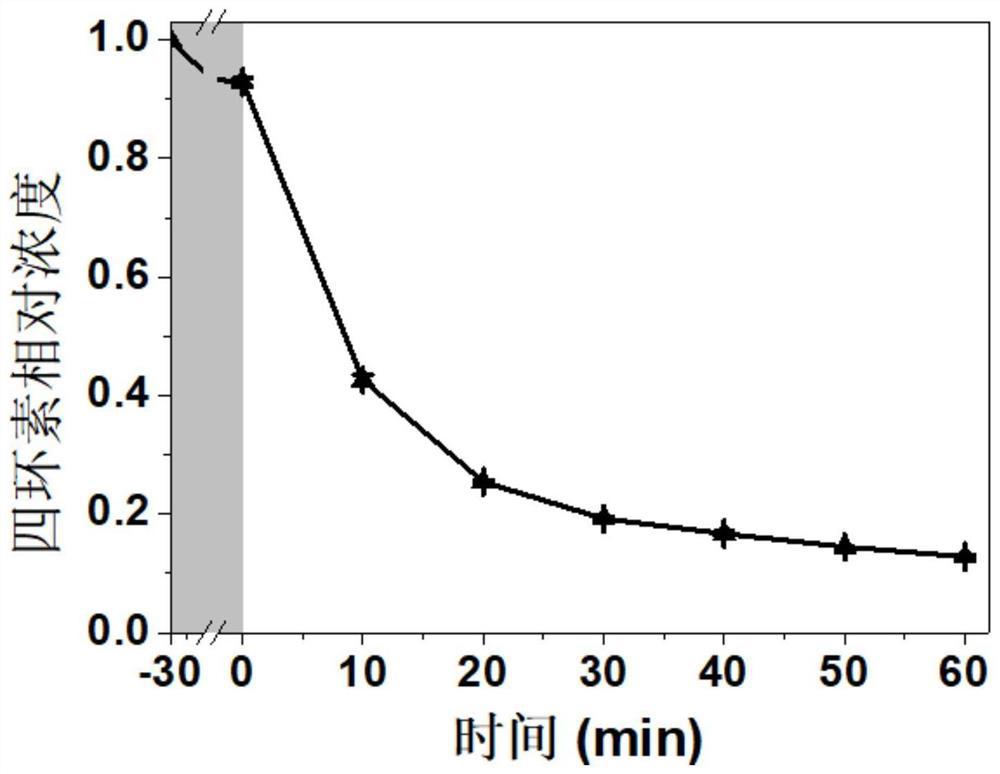

[0044] 1. The light-Fenton catalyst g-C prepared for this embodiment 3 N 4 / Fe 2 o 3 Take a transmission electron microscope, figu...

Embodiment 2

[0047] (1) Add 30g of urea to the crucible, add the crucible cover, and heat at 1.0°C min -1 The rate was heated to 550°C for 2h, and the resulting product was re-added to the crucible without the crucible lid, and then heated at 1.0°C min -1 The rate is heated to 500°C for 2h to obtain g-C 3 N 4 Nanosheets;

[0048] (2) the g-C obtained in step (1) 3 N 4 The nanosheets were added to the ethanol solution at a concentration of 4.0 g L -1 , Ultrasonic dispersion, add iron nitrate and ammonium bicarbonate to the dispersion in turn, the concentration is 1.0 and 3.0mol L -1 , stirred for 10h, separated by filtration, washed with deionized water and dried, and the dried product was heated at 1.0°C min -1 The rate is heated to 300 ° C for 2 h to obtain g-C 3 N 4 / Fe 2 o 3 Complex.

Embodiment 3

[0050] (1) Add 60g of urea to the crucible, add the crucible cover, and heat at 5.0°C min -1 Heating at a rate of 550°C for 4h, adding the resulting product back into the crucible without the crucible lid, and then heating at 5.0°C min -1 The rate is heated to 500 ° C for 4 h to obtain g-C 3 N 4 Nanosheets;

[0051] (2) The g-C obtained in step (1) will be 3 N 4 The nanosheets were added to the ethanol solution at a concentration of 10.0 g L -1 , ultrasonically disperse, add ferric nitrate and ammonium bicarbonate to the dispersion in turn, the concentrations are 10.0 and 30.0mol L -1 , stirred for 10h, separated by filtration, washed with deionized water and dried, and the dried product was heated at 5.0°C min -1 The rate is heated to 400 ° C for 4 h to obtain g-C 3 N 4 / Fe 2 o 3 Complex.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com