System and method for preparing hydrogen-rich gas and calcium carbide from calcium carbide slag

A technology of calcium carbide slag and calcium carbide, applied in chemical instruments and methods, hydrogen/synthesis gas production, hydrogen, etc., can solve problems such as raw material demand and waste of pyrolysis gas, reduce raw material cost, increase reaction contact area, increase heat The effect of utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

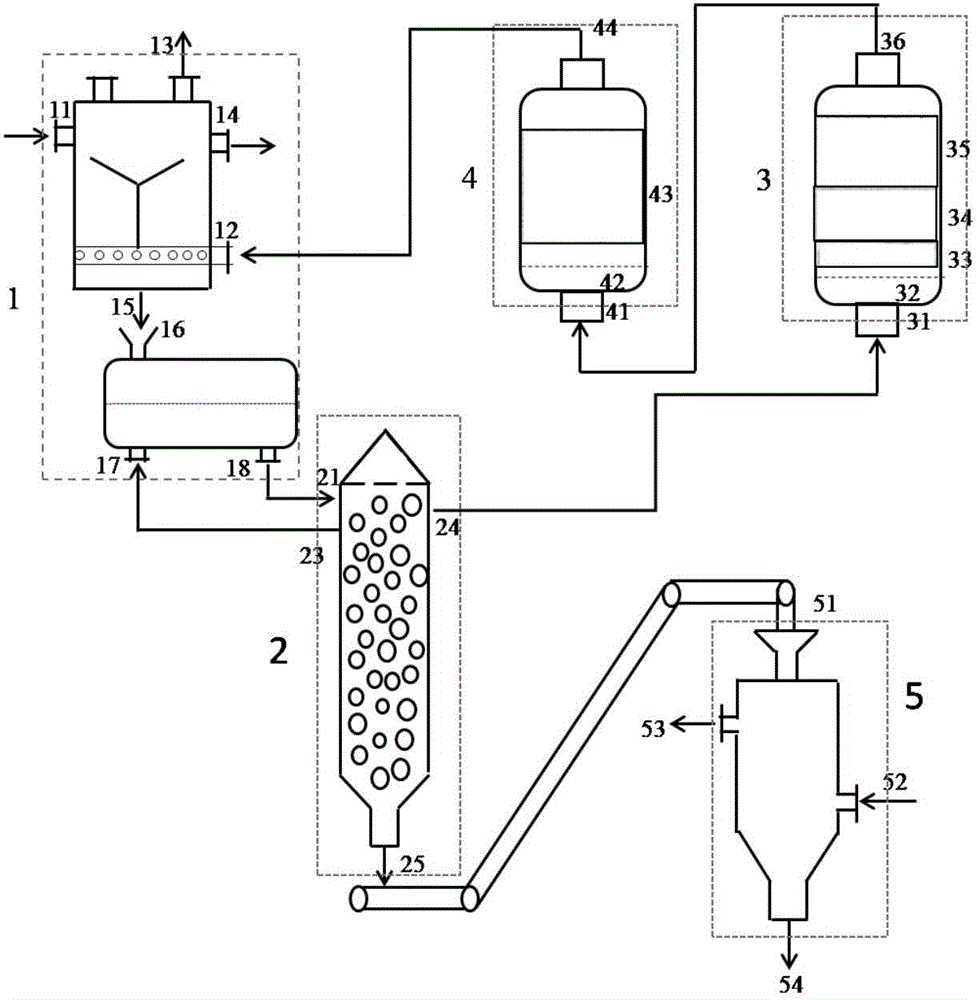

Image

Examples

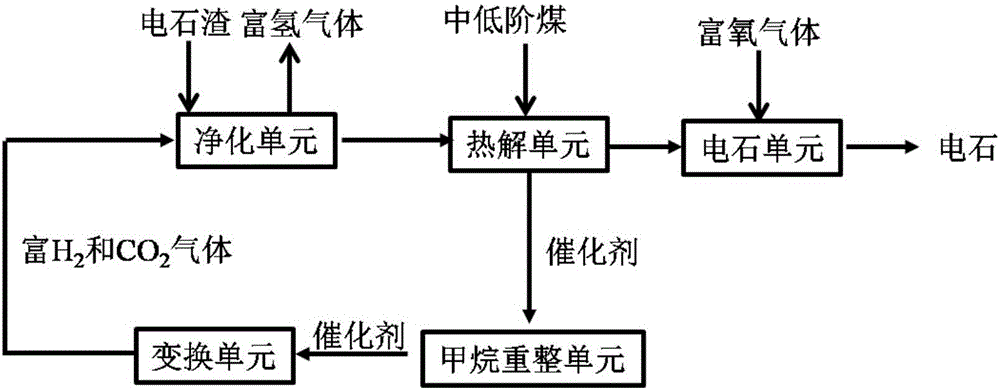

Embodiment 1

[0041] Using long-flame coal and calcium carbide slag as raw materials, the calcium carbide slurry is first added to the purification tank, and CO-enriched gas is introduced from the bottom of the purification tank while stirring continuously. 2 and H 2 Gas, adjust the pH of the calcium carbide slurry to 8-11. Calcium hydroxide, the main component in calcium carbide slag, is carbonized into calcium carbonate, while the impurity magnesium oxide is reacted into water-soluble magnesium bicarbonate. After the carbonized solid is preliminarily precipitated, it is sent to the drying device, and is subjected to heat exchange and drying with the countercurrent flue gas at 200°C to obtain the dried carbonized solid. Then the dried carbonized solid is sent to the pyrolysis unit, mixed with coal powder at a mass ratio of 1.2:1, and pyrolyzed at 900°C for 30 minutes to obtain raw coal gas and high-temperature mixed powder. The raw coal gas is directly transported to the catalytic reform...

Embodiment 2

[0043] Using long-flame coal and calcium carbide slag as raw materials, the calcium carbide slurry is first added to the purification tank, and CO-enriched gas is introduced from the bottom of the purification tank while stirring continuously. 2 and H 2 Gas, adjust the pH of the calcium carbide slurry to 8-11. Calcium hydroxide, the main component in calcium carbide slag, is carbonized into calcium carbonate, while the impurity magnesium oxide is reacted into water-soluble magnesium bicarbonate. After the carbonized solid is preliminarily precipitated, it is sent to the drying device, and is subjected to heat exchange and drying with the countercurrent flue gas at 200°C to obtain the dried carbonized solid. Then the dried carbonized solid is sent to the pyrolysis unit, mixed with coal powder at a mass ratio of 1.8:1, and pyrolyzed at 900°C for 30 minutes to obtain raw coal gas and high-temperature mixed powder. The raw coal gas is directly transported to the catalytic reform...

Embodiment 3

[0045] Using long-flame coal and calcium carbide slag as raw materials, the calcium carbide slurry is first added to the purification tank, and CO-enriched gas is introduced from the bottom of the purification tank while stirring continuously. 2 and H 2 Gas, adjust the pH of the calcium carbide slurry to 8-11. Calcium hydroxide, the main component in calcium carbide slag, is carbonized into calcium carbonate, while the impurity magnesium oxide is reacted into water-soluble magnesium bicarbonate. After the carbonized solid is preliminarily precipitated, it is sent to the drying device, and is subjected to heat exchange and drying with the countercurrent flue gas at 200°C to obtain the dried carbonized solid. Then the dried carbonized solid is sent to the pyrolysis unit, mixed with coal powder at a mass ratio of 1.5:1, and pyrolyzed at 900°C for 30 minutes to obtain raw coal gas and high-temperature mixed powder. The raw coal gas is directly transported to the catalytic reform...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com