A method for multi-gas co-production and production capacity replacement in coal-measure strata

A technology of coal-measure strata and coal seam, which is applied in the field of multi-gas co-production and production capacity replacement in coal-measure strata, can solve the problems of large water production of coalbed methane, damage to low-pressure reservoirs, and pressure mismatch, etc., to prolong the stable production time and prolong gas wells The effect of service life and reduction of production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

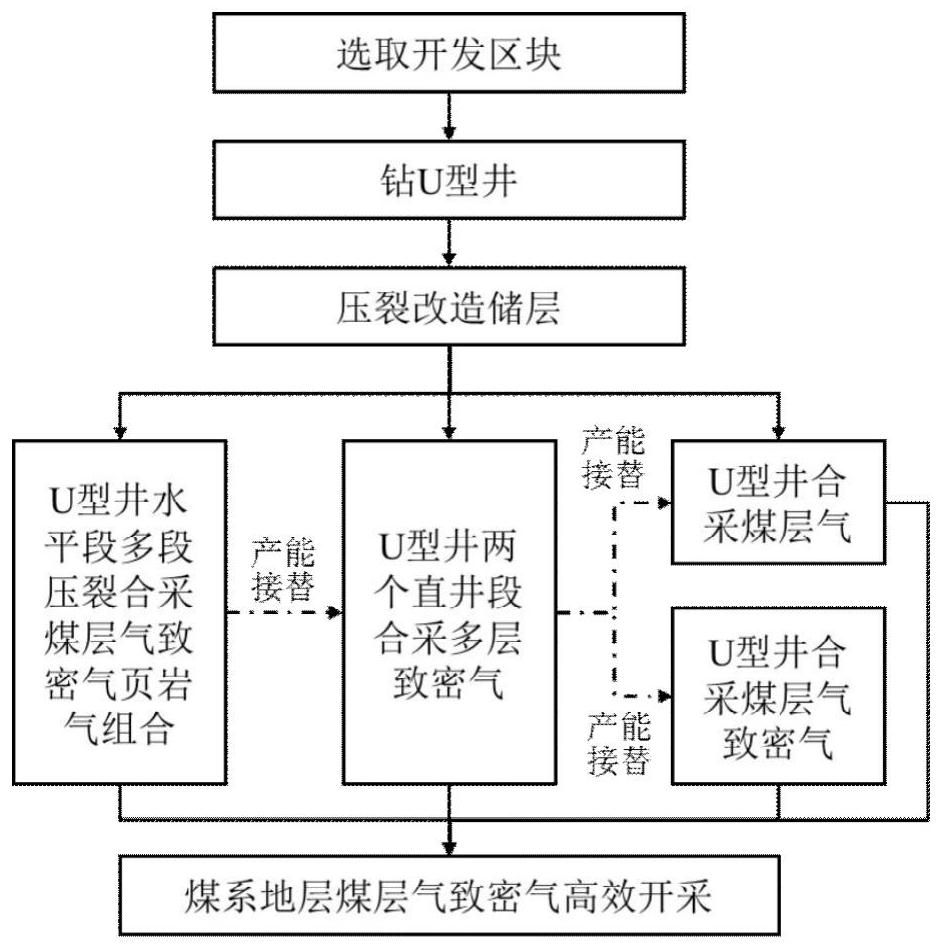

[0035] refer to Figure 1-5 , a coal-measure formation multi-gas combined production and productivity replacement method, comprising the following steps:

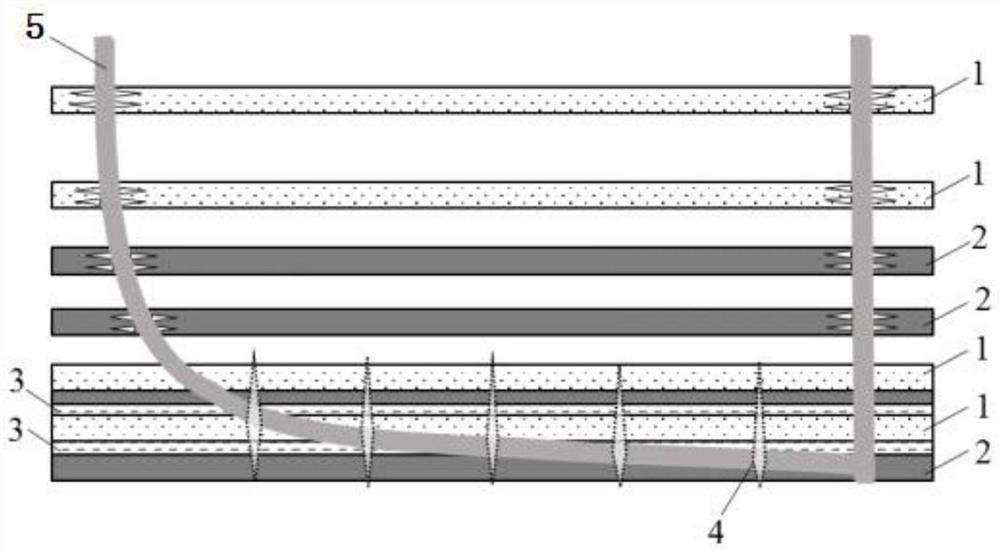

[0036] Step 1, in this block, the lower layer is the coal seam 2, the tight sandstone layer 1 and the shale layer 3 which are stacked and distributed at close distances, and the upper layer is distributed with the distant disconnected coal seam 2 and the tight sandstone layer 1. The U-shaped well 6 was drilled in the block. The horizontal well section of the U-shaped well 6 was inclined, and at the same time, the horizontal well section was drilled through the coal seam 2, the tight sandstone layer 1 and the mud shale layer 3 distributed in a short distance. The two vertical sections of the well are drilled vertically upward through multiple coal seams 2 or tight sandstone layers 1;

[0037] Step 2: After the completion of U-shaped well 1, the horizontal well section of U-shaped well 1 is fracturing by means of multi-stage...

Embodiment 2

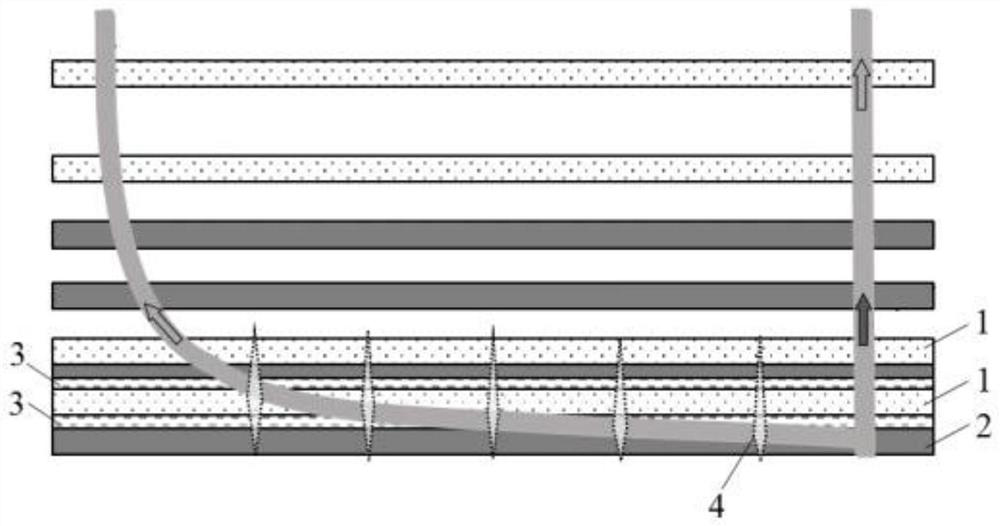

[0042] Refer to the attached Figure 1-3 , 6-8, Steps 1-3 are the same as Example 1, the only difference is Step 4: When the coal seam 2 in the upper part of the formation is located below the tight sandstone layer 1, a seal can be set between the coal seam 2 and the tight sandstone layer 1 Device 6, the specific setting method is as follows: the vertical well section with high structural level is set with full isolation, and the vertical well section with low structural level is set with annular isolation 61. At this time, the vertical well section with low structural level is used for gas production and drainage. When the dynamic liquid level of the coal seam is lower than the upper sandstone layer, all packers are taken out and the overall commingled production is carried out. Among them, the vertical well section at the low structural level is drained by the pumping unit 9 arranged in the oil production pipe 7 , and the gas is produced by using the annulus between the well...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com