Swing arm and swing arm supporting structure of thin seam short-span coal mining machine

A supporting structure and swing arm technology, which is applied in the direction of slitting machinery, cutting machinery, earthwork drilling and mining, etc., can solve the problems of long suspension section of the fuselage, large influence of force on the whole machine, lengthening of the fuselage, etc. Achieve the effects of stable and reliable power transmission, compact dimensions in the left and right directions, and improved stress stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

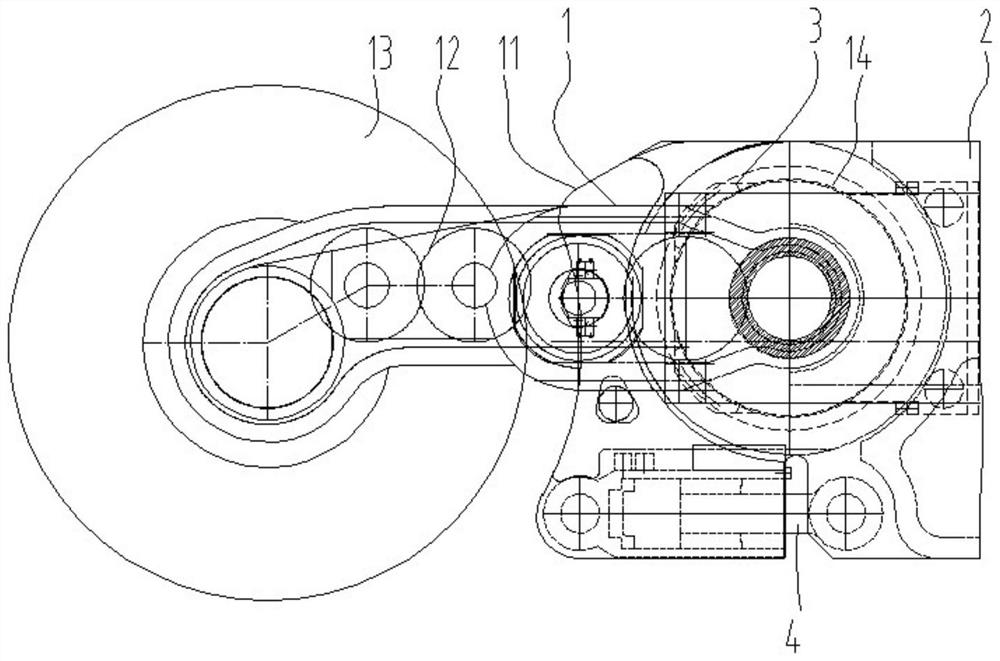

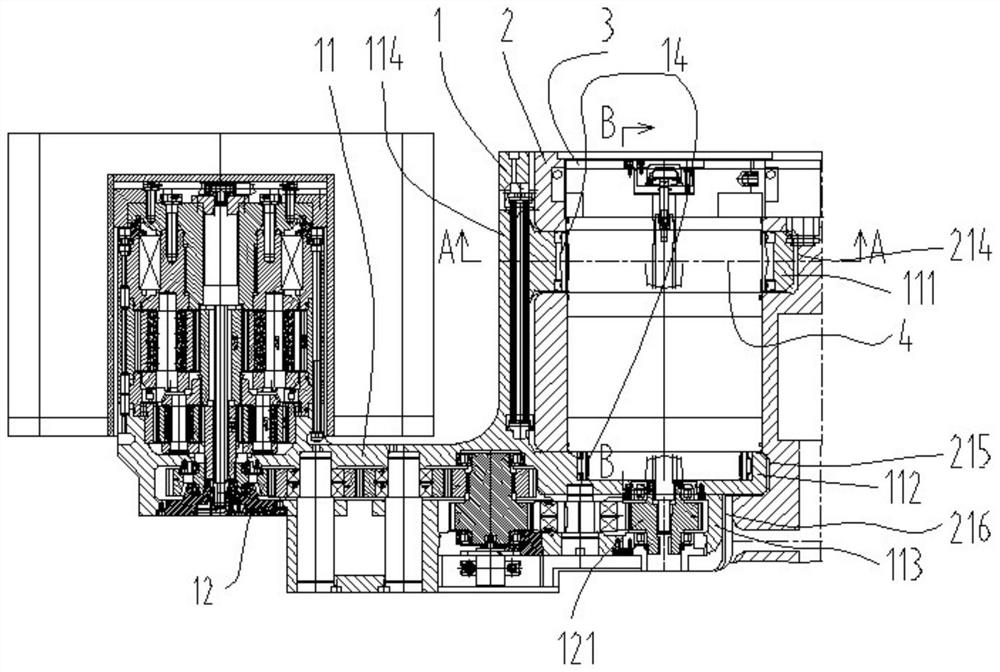

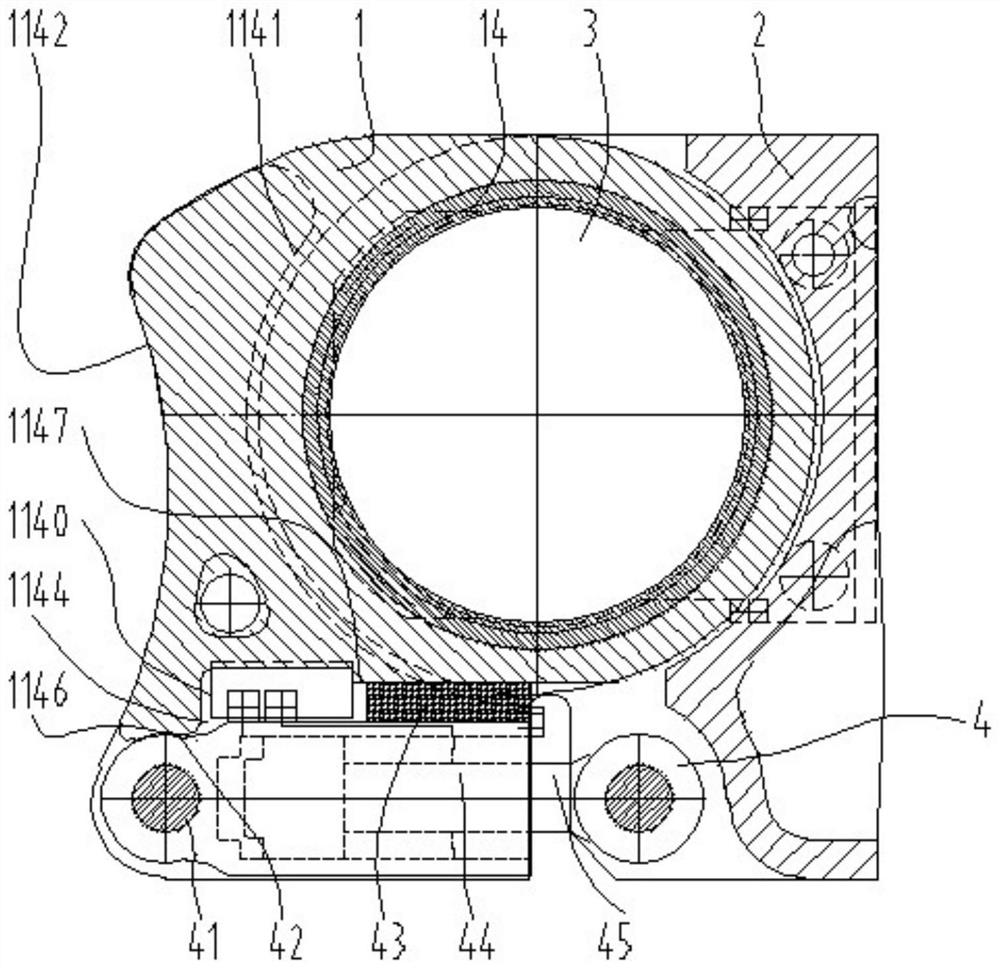

[0036] The invention discloses a thin coal seam short-span shearer swing arm 1 (which can be referred to simply as the swing arm), as Figure 1-6As shown, a swing arm housing 11 is included, the main body of the swing arm housing is an arm frame extending left and right, and a cutting transmission mechanism 12 is installed in the arm frame. The cutting transmission mechanism adopts the fixed shaft gear transmission mechanism. In order to easily distinguish the two ends of the boom, this paper regards the input end gear 121 (also the high-speed end gear) and the output end gear (also the low-speed end gear) of the cutting transmission mechanism as the high-speed end and the low-speed end of the boom respectively. The middle part of the boom frame is provided with a connecting arm 114 that cantilever forward from the boom frame, and the connecting arm is provided with a forearm 111 that cantilever left or right from the connecting arm. The connecting arm is cantilevered to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com