Spatial arrangement structure for ore removal level of ore body

A spatial layout and horizontal technology, which is applied in ground mining, underground mining, special mining, etc., can solve the problem that the horizontal spatial layout structure of the mine needs to be improved, and achieve the effect of expanding the mining range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

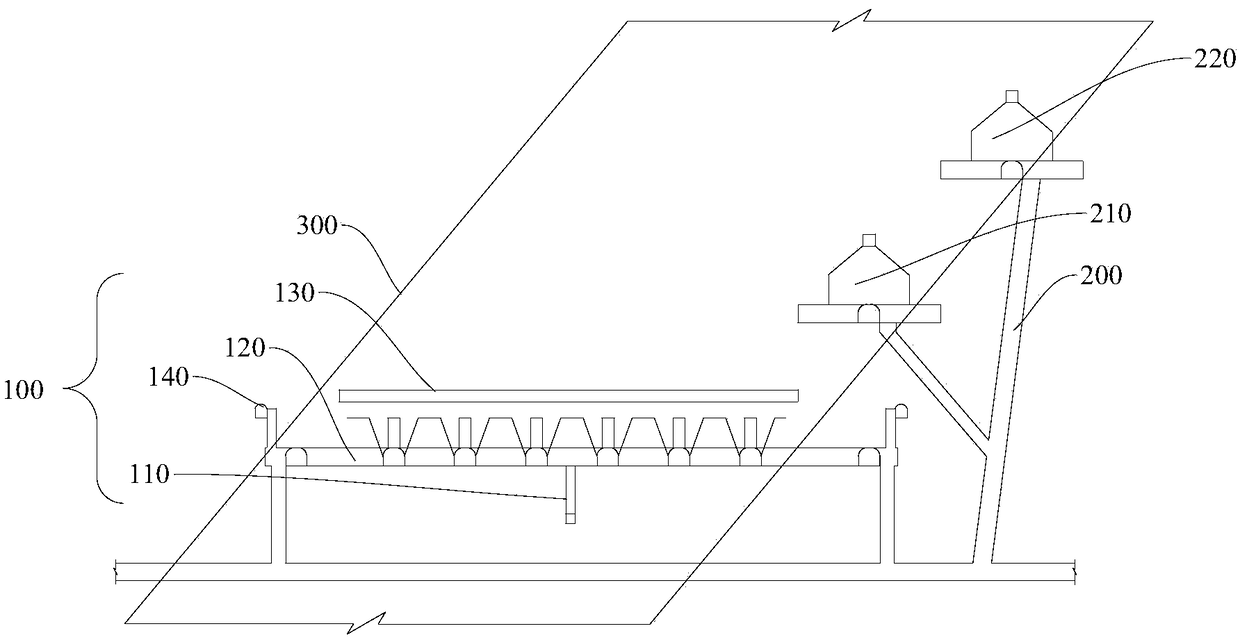

[0036] The 4# and 5# ore bodies of a certain copper deposit are huge lenticular on the plane, and plate-like along the inclination, tending to the northwest, and the inclination angle is 40°~60°. Natural caving method is adopted to recover the inclined ore bodies in foreign mines. did not appear. Because the inclination angle of the ore body is relatively slow, in order to improve the mining recovery rate and reduce the production cost, the spatial arrangement structure of the ore discharge level of the ore body in the embodiment of the present invention is used to arrange the space of the ore discharge level of the footwall of the ore body. The layout structure is as follows figure 1 As shown, two sub-layers of 584m and 614m are set in the footwall of the 4# ore body, and two sub-layers of 583m and 603m are set in the footwall of the 5# ore body. The main layer and the sub-layer are arranged in a stepped manner. That is to say, the ore level of the main layer is arranged at a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com