Method for mining underground sodium sulfate decahydrate by drilling hot water dissolving

A technology of mirabilite ore and hot water, which is applied in the direction of mining fluid, earthwork drilling, borehole/well components, etc., which can solve the problems of high mining cost, low brine concentration, and low mining rate, so as to improve the utilization rate of ore deposits and improve The effect of brine concentration and heat balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

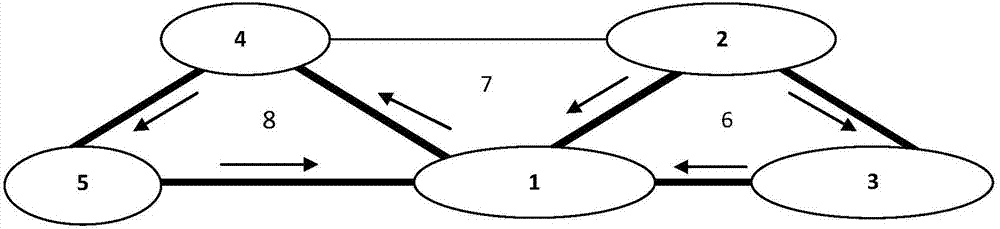

[0019] The present invention will be further described below in conjunction with accompanying drawing.

[0020] The invention collects the condensed hot water from the second to fourth effects of the four-effect vacuum evaporation in a closed pressure storage tank, and communicates with the hot water circulation tank of the tail gas circulation of the final effect, and the mixed hot water is pumped to the triangular connection of the drilling three wells through the pipeline by a high-pressure hot water pump. One horizontal well enters the well, and the vertical well and the other horizontal well go through triangular heating to dissolve the underground decaglauberite ore to dissolve the qualified sodium sulfate-containing brine. The water outlet pipe end of the horizontal well is equipped with a water outlet rotating device to form a water outlet rotation, in order to increase the speed and strength of ore dissolution. Increase brine concentration.

[0021] Due to the solubil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com