A layered mining pipe column for rock salt mine and a layered mining method for rock salt mine

A technology for layered mining and rock salt mines, applied in the fields of mining fluids, earthwork drilling, wellbore/well components, etc., can solve the problems of low mining speed and efficiency, complex downhole pipe strings, etc., to avoid interlayer interference, improve The effect of mining efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The invention will be further described below in conjunction with the accompanying drawings.

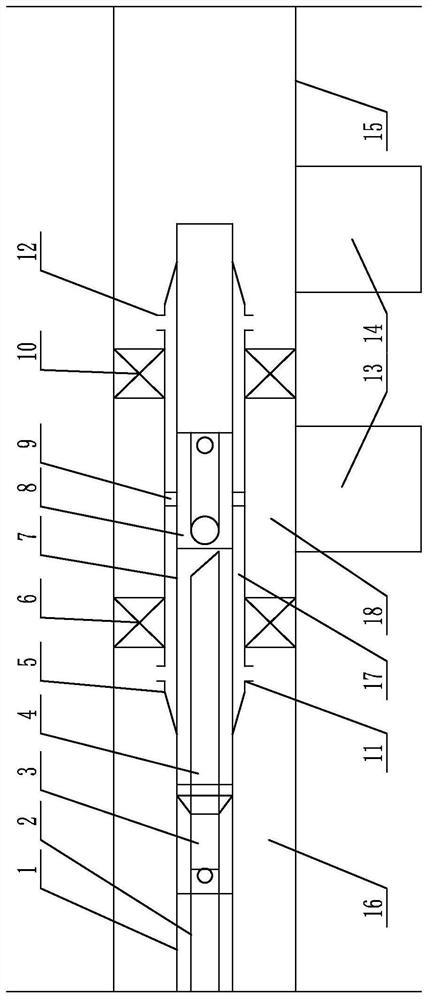

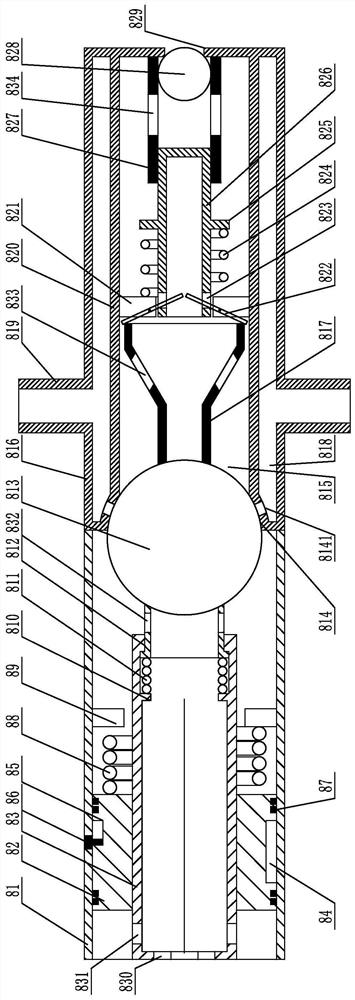

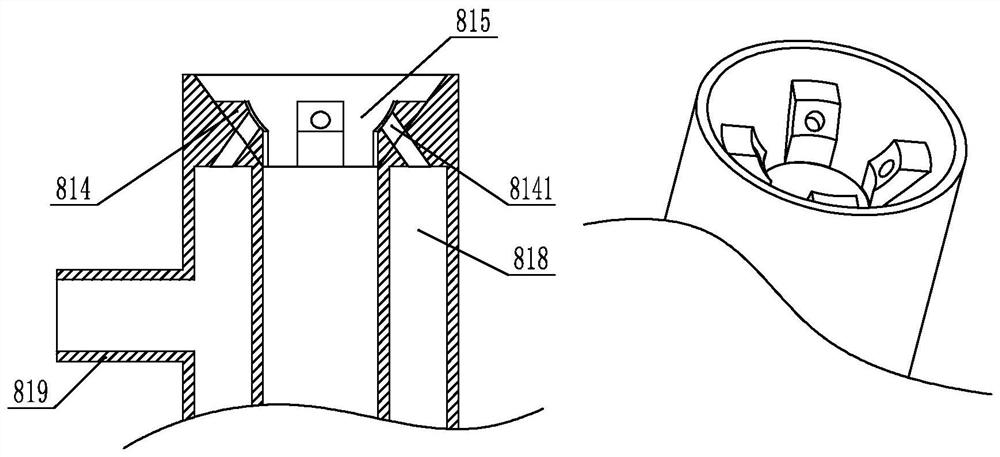

[0029]A pipe string for layered mining of rock salt mines, mainly including oil pipe 1, hollow rod 2, hollow pump 3, hollow mandrel 4, outer oil pipe 5, upper packer 6, inner oil pipe 7, flow channel conversion nipple 8, bridge The lower end of the oil pipe 1 is connected to the hollow pump 3, and the lower end of the hollow pump 3 is respectively connected to the outer oil pipe 5 and the inner oil pipe 7 through a double button joint, and the lower end of the outer oil pipe 5 is connected to the upper packer 6, The bridge channel 9, the lower packer 10, the upper packer 6 and the lower packer 10 are sealed on the inner wall of the casing 15, the lower end of the inner oil pipe 7 is connected to the flow channel conversion nipple 8, the outer oil pipe 5 and the inner oil pipe 7 The lowermost end continues to connect to the tubing 1 through a double-button joint, the side of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com