Control method for preventing steel coil inner ring from core pulling during coil stripping of coiling machine

A control method and coiler technology, which is applied in the field of automatic control of metallurgical cold rolling, can solve the problem of uncontrollable reel jaws, smaller gaps, and inability to completely eliminate the jamming of the unloading head, scratches on the inner ring of the steel coil, and core pulling. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0086] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

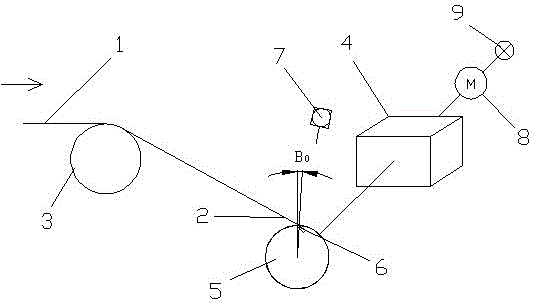

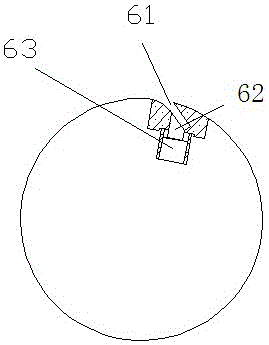

[0087] see figure 1 , 2 Before coiling steel strip 1 in the production line, the jaw mechanism 6 of the drum 5 is positioned at the angle A0 of the common tangent line between the drum 5 and the steering roller 3. After the coiling starts, the tape head 2 is introduced into the jaw 61 and is driven by the hydraulic cylinder. The depressing tongue 62 that 63 drives presses and clamps. Simultaneously, the motor of the coiler 4 drives the reel 5 to rotate clockwise.

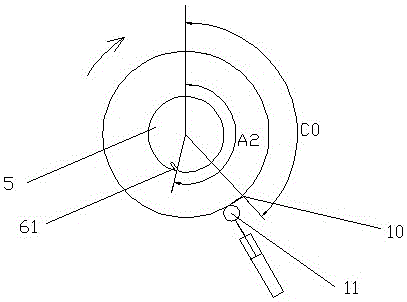

[0088] see image 3 , 4 , in order to avoid that the position of the jaw 61 cannot be precisely positioned after the coiling is completed and the belt tail 10 is positioned in the prior art, and the jaw 61 stops at a position such as Figure 4 (a) The area shown in (b) leads to problems such as difficulty in opening the jaw 61 and too small gap with the inner ring of the steel coil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com