Pb-free sn-based material, wiring conductor, terminal connecting assembly, and pb-free solder alloy

A terminal connection and conductor technology, applied in the direction of metal/alloy conductor, metal material coating process, welding/cutting medium/material, etc., can solve problems such as short circuit of adjacent wiring materials, and achieve short circuit and high connection reliability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

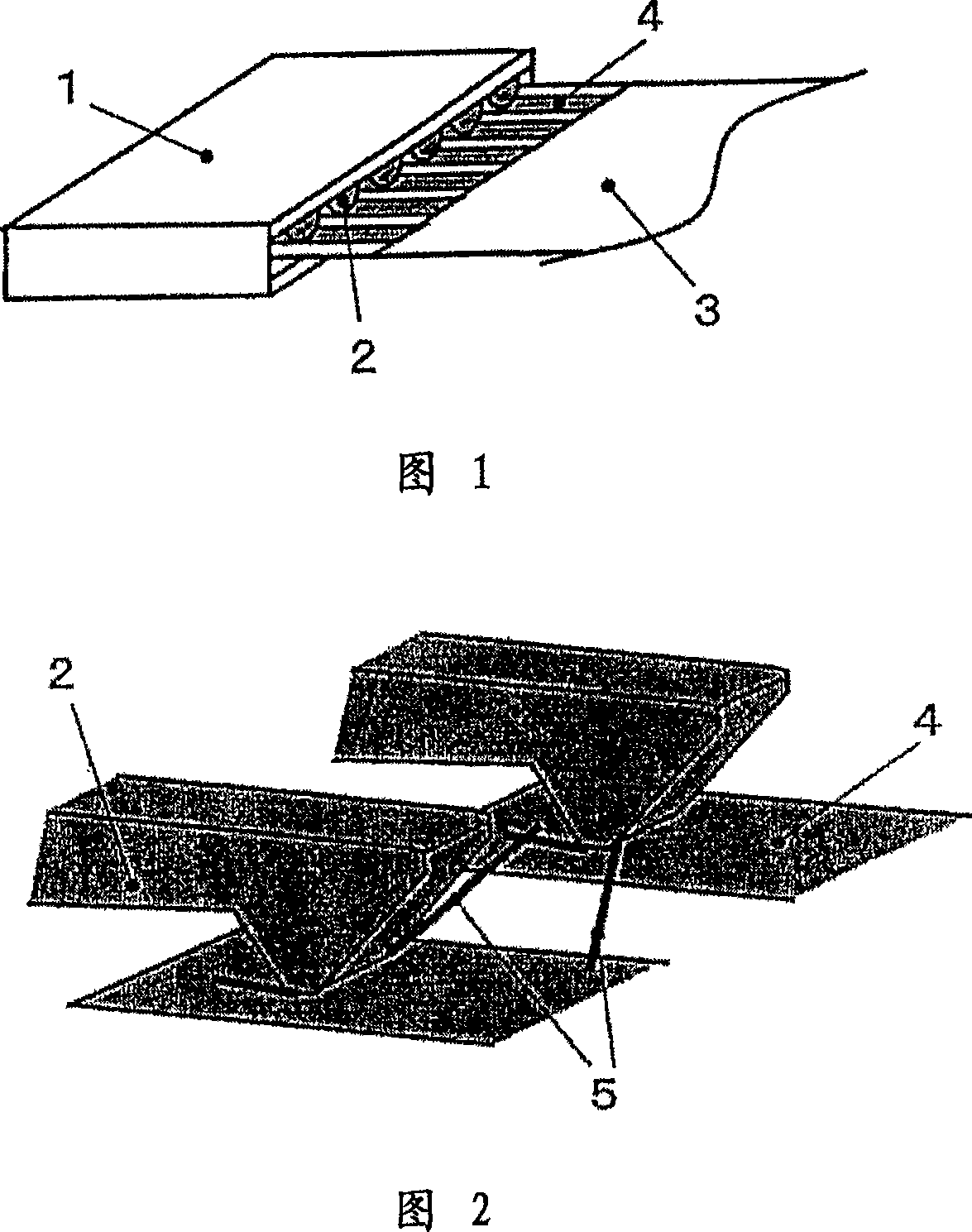

Image

Examples

Embodiment approach

[0054] In the wiring conductor of the present embodiment, a Pb-free Sn plating film is provided on the entire surface (at least part of the surface) of a metal conductor, and a phase change retardation element layer and an oxidation suppressing element are provided on the upper layer of the Sn plating film The layer is then formed by reflow treatment, and has a Pb-free Sn coating layer on the entire surface of the metal conductor.

[0055] The Pb-free Sn coating layer is a layer mainly composed of an alloy of phase change delay elements, oxidation inhibitor elements, and Sn. The entire layer may be composed of alloys, or a part of the layer may have some phase change delay elements remaining Any one of a layer, a layer of an oxidation inhibiting element, and a Sn plating film.

[0056] Relative to the weight of the Sn plating film, the weight ratio of the layer of the phase change retardation element and the layer of the oxidation inhibitor is 0.001 to 10 wt%, preferably about 0.1...

Embodiment

[0067] Respectively adopt

[0068] (a) In pure Sn, 0.01wt% of phase change delay element (any one of Sb, Bi, In, Ag, Au, Ni, Ti, Zr, Hf) and 0.01wt% of oxidation inhibitor ( Any one of Ge, Zn, P, K, Mn, V, Si, Al, Mg, Ca) materials;

[0069] (b) Add 0.01wt% of phase change delay element (Bi), 0.01wt% of phase change delay element (Ni) and 0.01wt% of oxidation inhibitor (either P or Zn) to pure Sn. material;

[0070] (c) Add 1wt% of phase change delay element (any one of Sb, Bi, In, Ag, Au) and 0.01wt% of oxidation inhibitor (Zn, P, K, Mn, V) to pure Sn. Any one of) materials;

[0071] (d) Add 0.1wt% of phase change delay element (any one of Ni, Ti, Zr, Hf) and 0.01wt% of oxidation inhibitor (Si, P, Zn, Ge, Al, Any one of Mg and Ca) materials;

[0072] (e) In pure Sn, 1wt% of phase change delay element (Bi), 0.1wt% of phase change delay element (Ni), and 0.01wt% of oxidation inhibitor (either P or Zn) are added to the material ;

[0073] (f) A material in which only 0.01 wt% of pha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com