J-shaped entrained-flow gasifier

A gasifier and entrained bed technology, which is applied in the mechanical details of gasification devices, the gasification of granular/powder fuels, and the manufacture of combustible gases, etc., can solve the problem of reducing energy utilization efficiency, low carbon conversion rate, and waste of high-level heat energy of synthesis gas. and other problems, to achieve the effect of alleviating the ash problem in the heated area, improving the carbon conversion rate and reducing the amount of fly ash

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

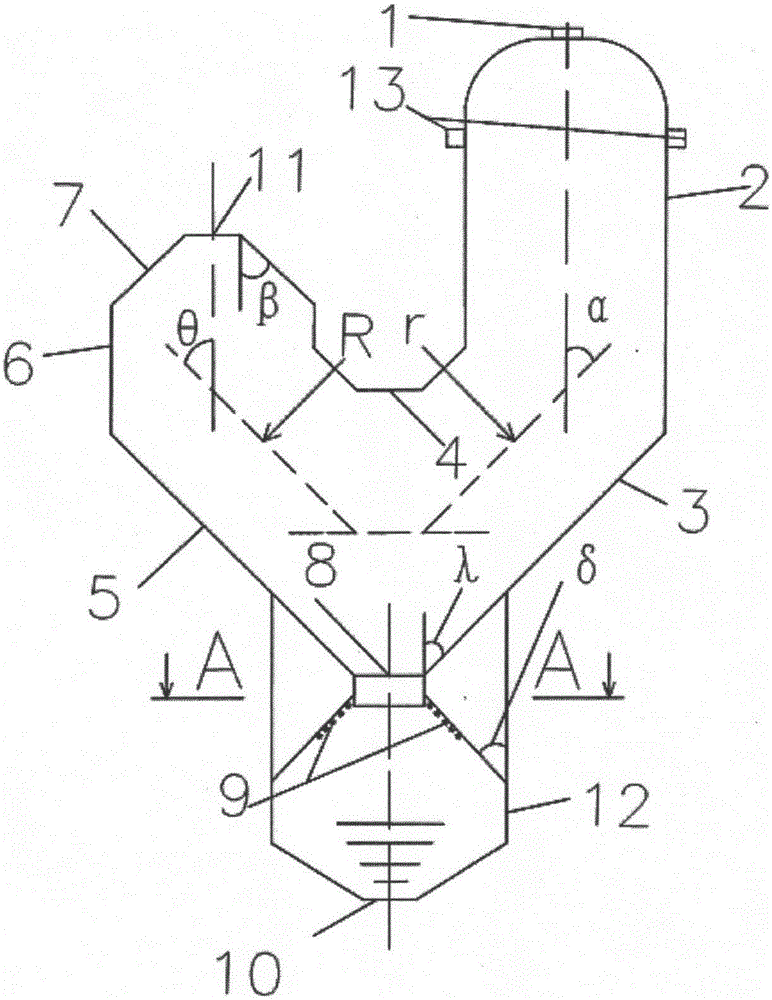

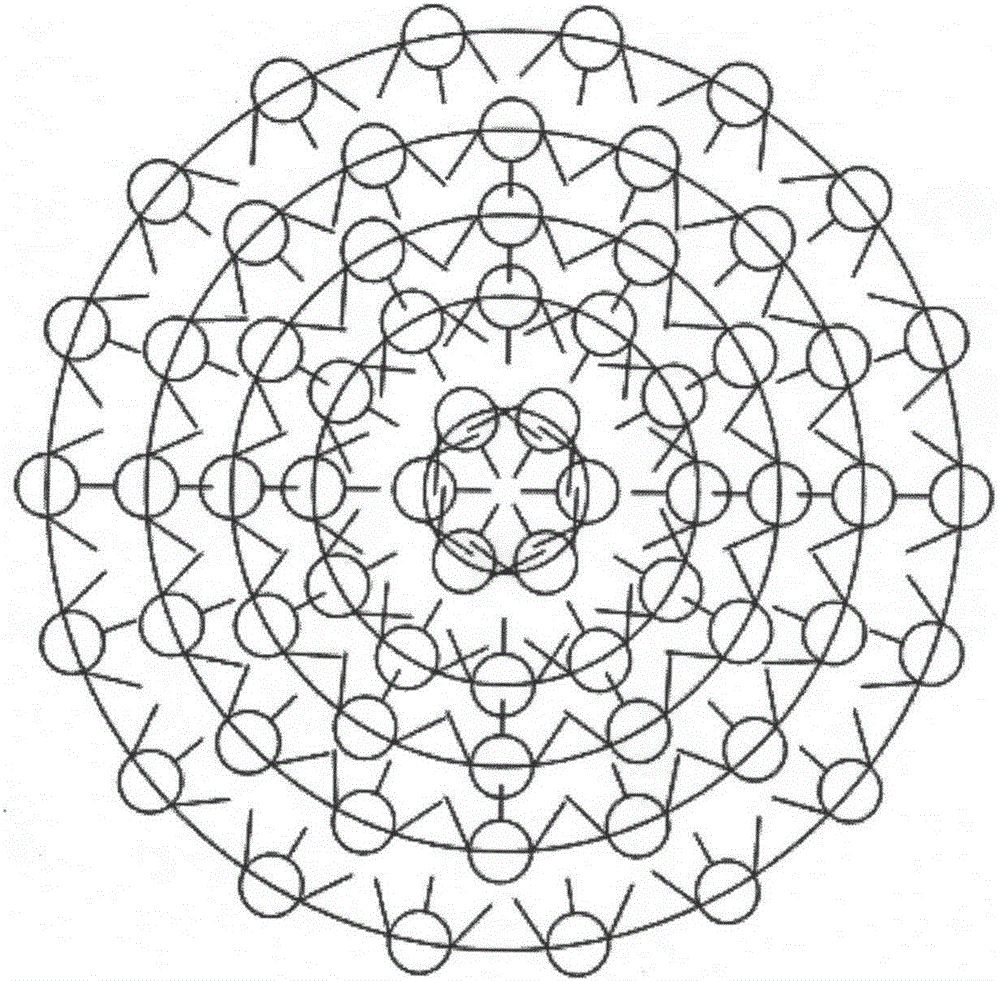

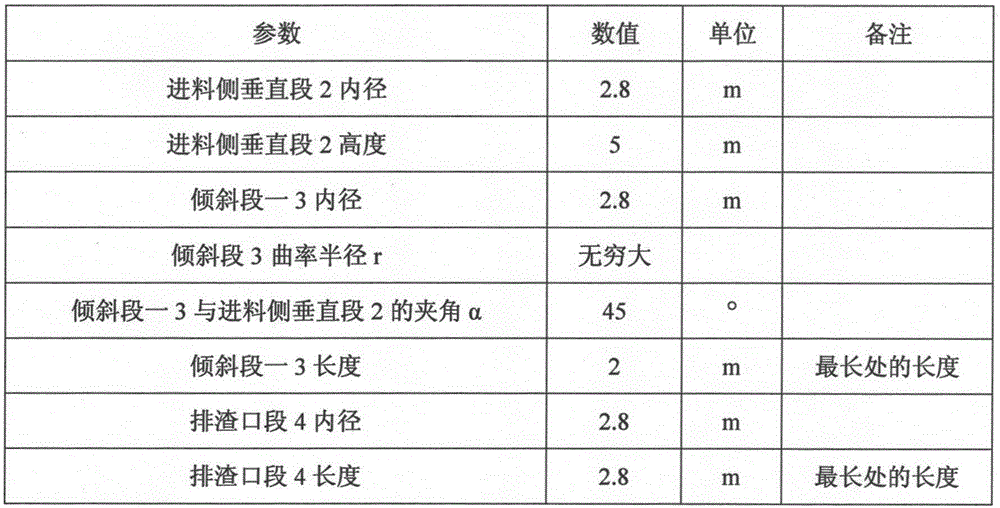

[0037] A J-type entrained-bed dry coal pulverized coal gasifier with a daily processing capacity of 2,000 tons of coal has a gasification pressure of 4.0 MPa. The inner wall is a water-cooled wall structure, and a gasification burner is installed on the top of the higher side of the gasifier. The main size parameters of the gasifier are shown in Table 1:

[0038] Table 1 Main dimension parameters of gasifier

[0039]

[0040]

[0041] Pure oxygen (99.6) gas and water vapor are used as gasification agents, and N2 is used as carrier gas to transport pulverized coal in pressurized dense phase. The oxygen-to-coal ratio is 0.88 (kg / kg dry basis), the steam oxygen ratio is 0.01 (kg / kg), and the gas-solid ratio of pulverized coal transportation is 9 (KG / KG). The coal quality analysis data of the coal used are shown in Table 2~ As shown in Table 5, the technical indicators of the gasifier are shown in Table 6.

[0042] Table 2 Industry Analysis

[0043]

[0044] Table 3 el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com