Preparing heterojunction solar cell method of combining wet process deposition with low temperature heat treatment

A low-temperature heat treatment, solar cell technology, applied in the direction of circuits, electrical components, final product manufacturing, etc., can solve the problems of cumbersome process steps, complicated methods, increased fragmentation rate, etc., and achieve the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

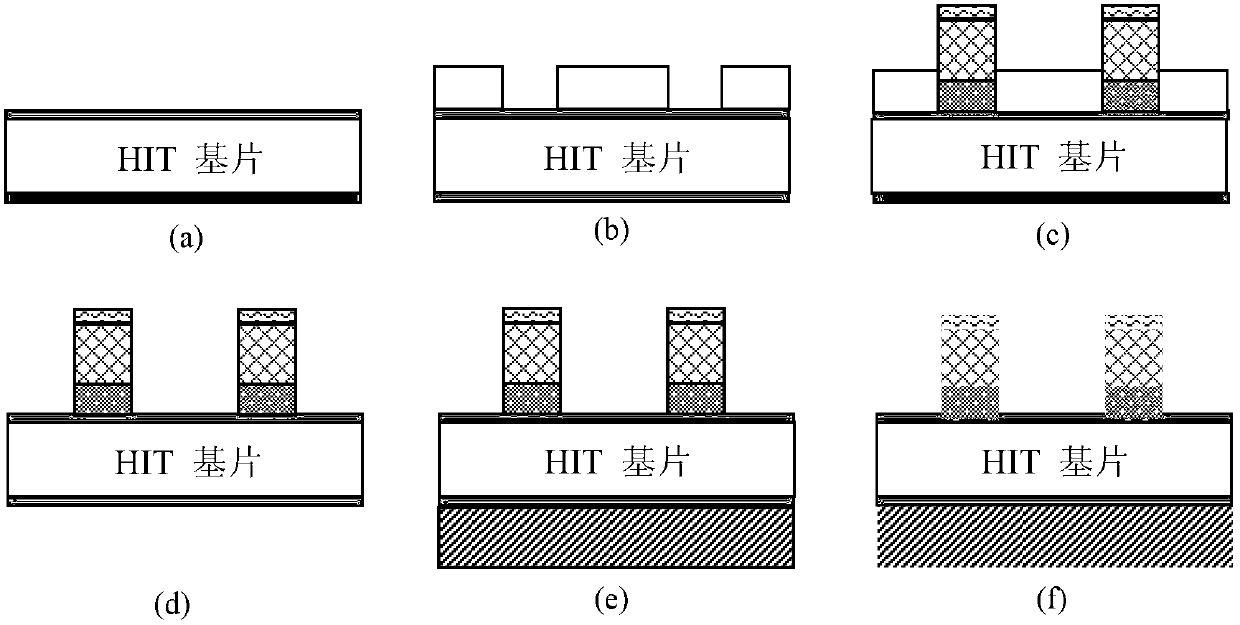

[0075] Example 1. Please see attached image 3

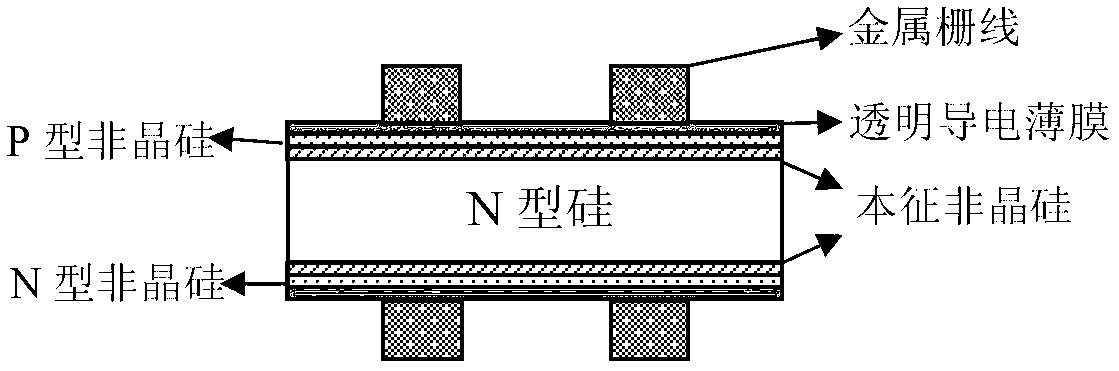

[0076] (a) forming a transparent conductive thin film layer on the heterojunction solar cell substrate, the substrate includes preparing a heterojunction solar cell on an n-type or p-type substrate, and depositing a transparent conductive thin film transparent thin film includes a Or a combination of several types, which can be deposited by PECVD, PVD, RPD, etc., with a thickness between 1nm and 1um.

[0077] The process steps of the transparent conductive thin film layer are:

[0078] a) Removal of damage and surface texturing of the crystalline silicon substrate;

[0079] b) Depositing an intrinsic amorphous silicon layer (i-type a-Si), about 0-50nm;

[0080] c) Depositing an n-type amorphous silicon layer (n-type a-Si), about 1-50nm;

[0081] d) Depositing an intrinsic amorphous silicon layer (i-type a-Si), about 0-50nm;

[0082] e) Depositing a p-type amorphous silicon layer (p-type a-Si), about 1-50nm;

[0083] f) Dep...

Embodiment 2

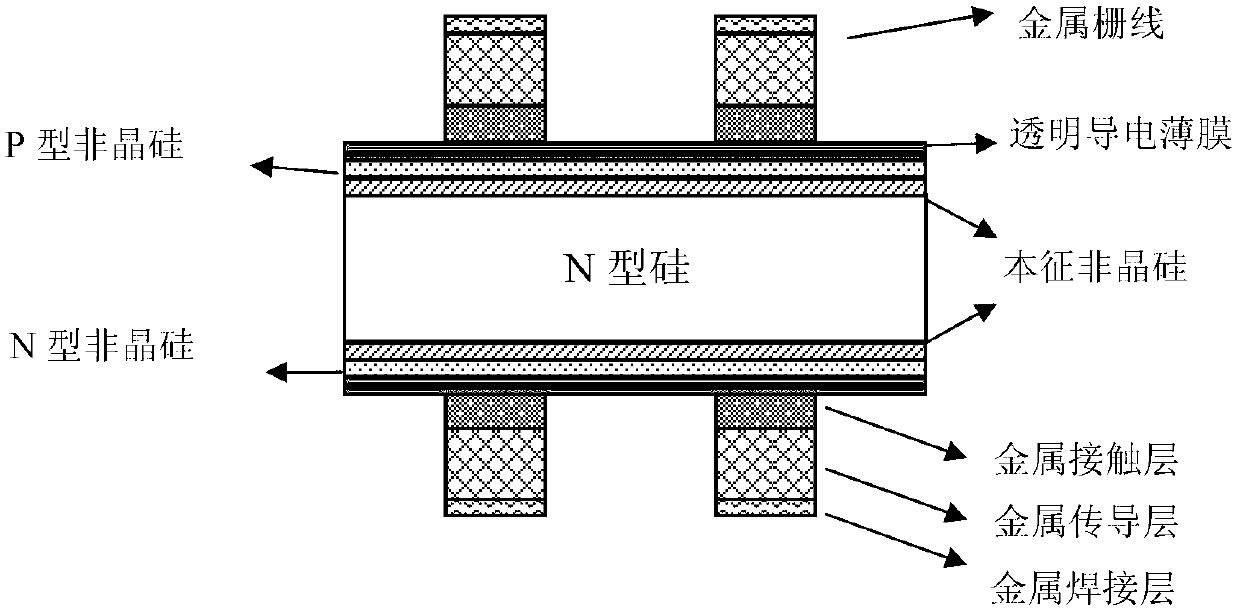

[0091] Example 2 (see Figure 4 )

[0092] Similar to Example 1, the present invention can also be used for double-sided electroplating of heterojunction solar cells, the specific process is as follows Figure 4 Shown is the derivation of embodiment 1, also belongs to the scope of technical protection of the present invention.

[0093] Steps (a)-(b) and steps (d) and (f) are similar to embodiment 1, step (e) does not need, and step (c) is:

[0094] (c) The metal grid lines are formed by double-sided wet deposition. Prepare metal grid lines at the opening of the mask and on the transparent conductive layer by electrodeposition, light-induced deposition, chemical deposition or a combination thereof, including Ni, Cu, Ag, Au, Cr, Pb, Sn, In, Bi, Metals such as Zn, Co, Cd, Sb or Tl and their combinations or alloys; since the mask is insulating, the deposition of metal is only carried out at the opening of the mask and on the transparent conductive layer, thereby forming the pat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com