Device for jet milling of viscous material and gathering of dust

A technology of airflow crushing and dust collection, which is applied in grain processing, etc. It can solve the problems of easy blockage of grinding chamber, grading wheel and pipeline, etc., and achieve the effect of less dust content, smooth inner wall and enlarged pipe diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

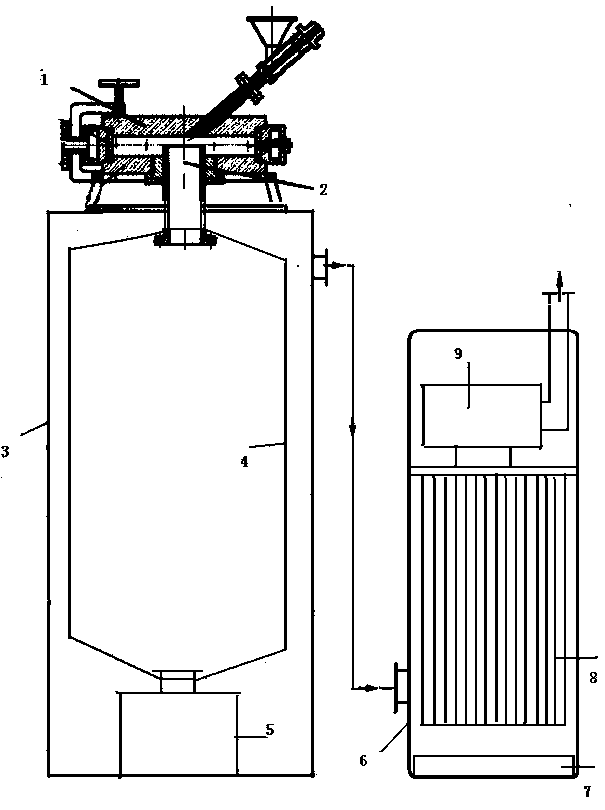

[0018] Such as figure 1 As shown, the present invention adopts a powder collecting box 3, and the gas-solid separation and material collection of pulverized products are all completed in the powder collecting box 3, and the powder collecting box 3 operates under negative pressure, so there will be no dust leakage on the production site; 1 (this embodiment uses a flat airflow mill with a lower discharge structure) fixed on the powder collecting box 3, and the parts in contact with the material inside the airflow mill 1 are all finely machined and wear-resistant ceramic parts with a smooth surface, which can reduce the stickiness of the material. Attachment: Jet mill 1 is a quick-install structure, which can be quickly opened and cleaned to realize rapid cleaning of the grinding chamber and ensure normal production; adjust the pressure of the main air and auxiliary gas for feeding in the jet mill 1 to reach the specified value to ensure that The feed port is under negative press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com