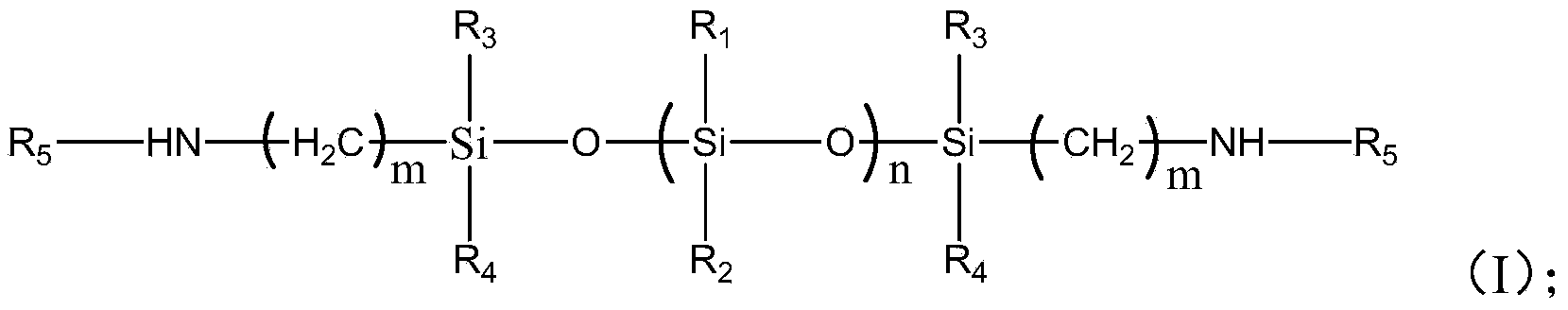

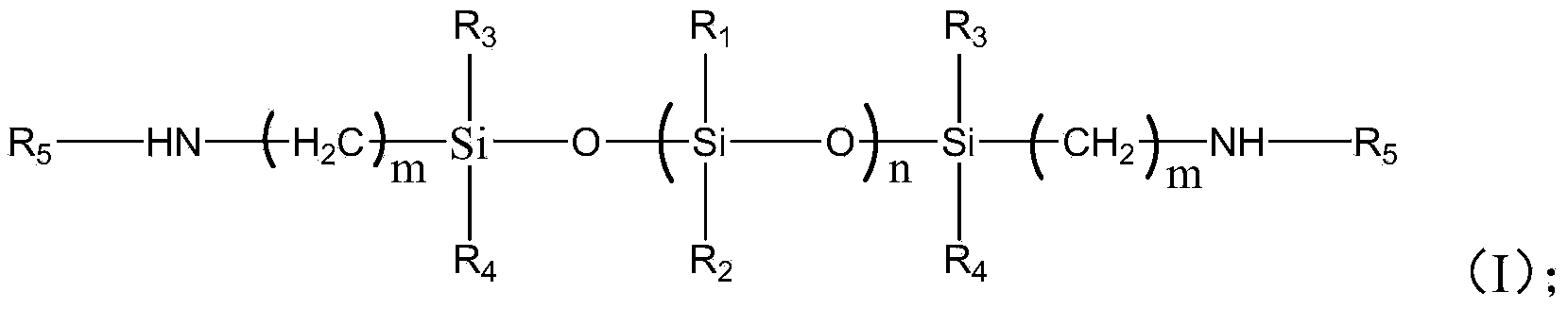

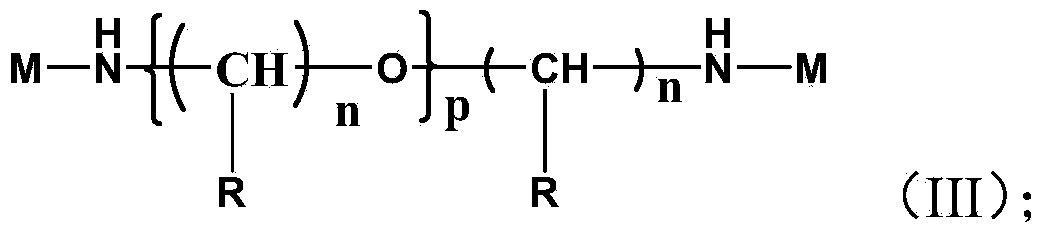

Polyureas copolymer with main chain containing siloxane composition unit and preparation method thereof

A technology of structural units and copolymers, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problems of low surface energy of polyurea, unfavorable for industrial scale production, difficult to prepare and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] This example prepares polyurea copolymers containing siloxane structural units from prepolymer A and prepolymer B according to the molar ratio of 1.1:1, wherein the molar fraction of each component in prepolymer A and prepolymer B The mole fraction of each component in is as shown in table 1:

[0047] Table 1 Example 1 The molar fraction of each component of prepolymer A and each component of prepolymer B

[0048]

[0049]

[0050] The preparation method of the polyurea copolymer containing siloxane structural unit of the present embodiment, it may further comprise the steps:

[0051] 1) 60 molar parts of MDI and 20 molar parts of polytetrahydrofuran diol (M n =2000) into the reaction flask, react at room temperature for 4 hours at a stirring speed of 200-300rpm, and then add 15 molar parts of polytetrahydrofuran diol (M n =2000) and 5 mole fractions of polytetrahydrofuran trihydric alcohol were stirred for 30 minutes, and then heated to 70°C to react to the sto...

Embodiment 2

[0055] In this example, a polyurea copolymer containing siloxane structural units is prepared from prepolymer A and prepolymer B according to a molar ratio of 1.0:1, wherein the molar fraction of each component in prepolymer A and prepolymer B The molar fraction of each component in is as shown in table 2:

[0056] The molar fraction of each component of table 2 embodiment 2 prepolymer A and each component of prepolymer B

[0057]

[0058]

[0059] The preparation method of the polyurea copolymer containing siloxane structural unit of the present embodiment, it may further comprise the steps:

[0060] 1) Linear polysiloxane (M n =600) and 15 mole fractions of polytetrahydrofuran diol (M n =2000) into the reaction flask, react at room temperature for 3 hours at a stirring speed of 200-300rpm, and then add 15 molar parts of polytetrahydrofuran diol (M n =2000) and 5 mole fractions of polytetrahydrofuran trihydric alcohol were stirred for 30 minutes, and the temperature ...

Embodiment 3

[0064] This example prepares polyurea copolymers containing siloxane structural units from prepolymer A and prepolymer B according to the molar ratio of 1.1:1, wherein the molar fraction of each component in prepolymer A and prepolymer B The molar fraction of each component in is as shown in table 3:

[0065] The mole fraction of each component and each component of prepolymer B in the embodiment 3 prepolymer A of table 3

[0066]

[0067]

[0068] The preparation method of the polyurea copolymer containing siloxane structural unit of the present embodiment, it may further comprise the steps:

[0069] 1) Polymethylmethoxysiloxane (M n =600) and 15 mole fractions of polytetrahydrofuran diol (M n=2000) into the reaction flask, react at room temperature for 5 hours at a stirring speed of 200-300rpm, and then add 10 molar parts of polytetrahydrofuran diol (M n =2000) and 5 mole fractions of polytetrahydrofuran trihydric alcohol were stirred for 30 minutes, and the tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com