MEMS micro array structure processing method based on micro-electroplating

A technology of micro-array and processing technology, which is applied in the direction of technology for producing decorative surface effects, micro-structure technology, micro-structure devices, etc., and can solve problems such as poor adhesion and uneven coating metal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below in conjunction with accompanying drawing and embodiment the present invention will be further described

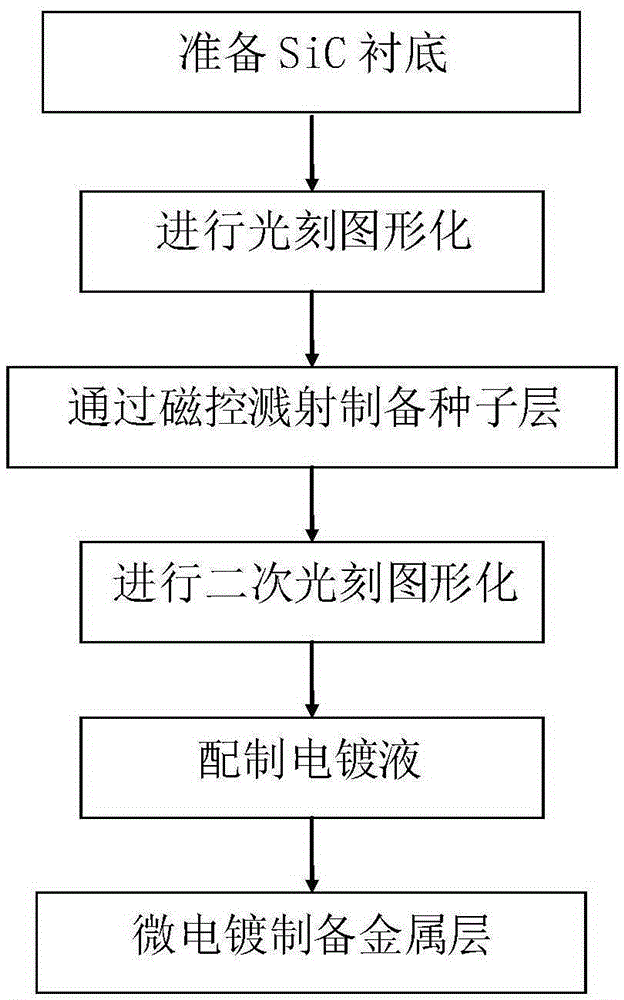

[0012] A kind of MEMS micro-array structure processing process based on micro-electroplating of the present invention (such as figure 1 shown), including the following steps:

[0013] Step 1, preparing the SiC substrate: the substrate is a SiC wafer, polished on both sides, and cleaned by RCA.

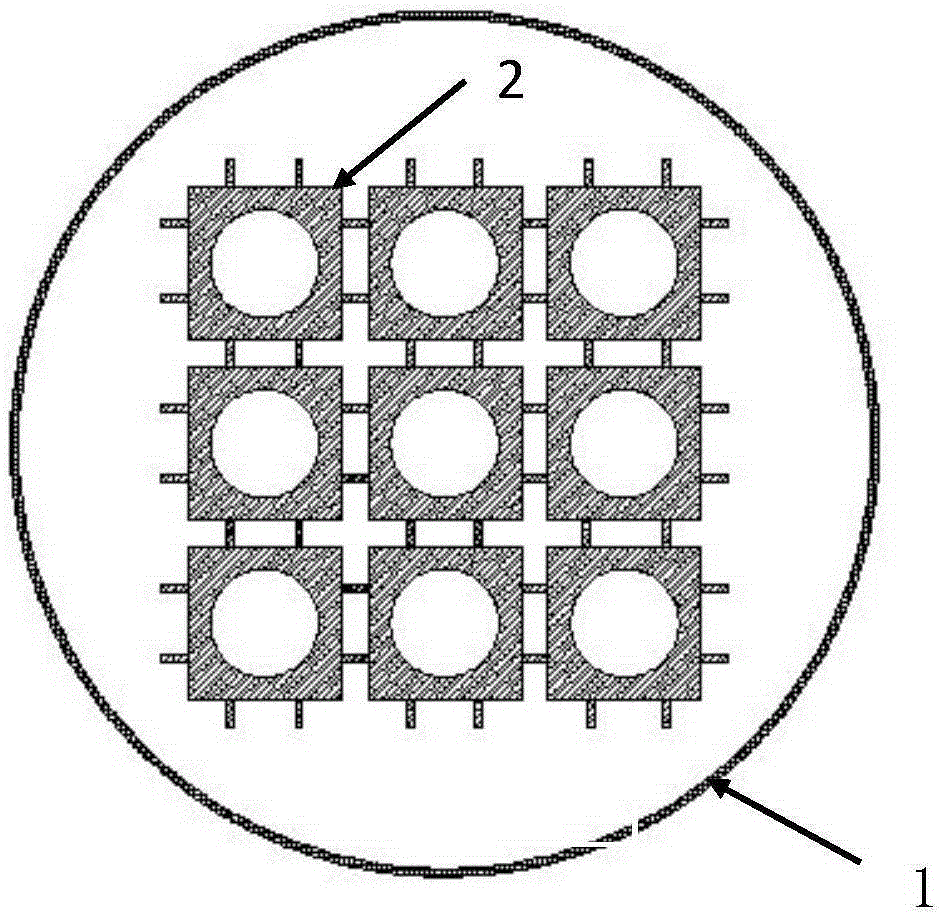

[0014] Step 2, carry out photolithography patterning, use Unicom microstructure (such as figure 2 shown), 1 in the accompanying drawings is a SiC wafer, and 2 is a Unicom microstructure.

[0015] On the wafer 1, evenly coat a photoresist of about 1-5 μm with a glue leveler, place it on a glue baking table at a temperature of 100°C for 3 minutes, and use a UV photolithography machine to expose it for 50 seconds, and develop it for 40 seconds. Put it on the rubber baking table for 10min to harden the film.

[0016] Step 3, prepare the seed layer: put the patterned s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com