Diethylenetriamine amido low molecular weight 650 epoxy hardener used for epoxy polyamide coating and preparation method and application thereof

A diethylenetriamine-based, epoxy polyamide technology, applied in epoxy resin coatings, coatings and other directions, can solve problems such as increasing costs, and achieve the effects of high production efficiency, smooth and bright board surface, and strong controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 1. Diethylenetriamine-based low molecular weight 650 epoxy curing agent for epoxy polyamide paint, which is made of the following raw materials in parts by weight:

[0026] Diethylenetriamine 160g, dimer acid 280g, fatty acid 141g, bisphenol A epoxy resin 60g, phenol 20g, benzyl alcohol 20g, xylene 20g.

[0027] 2, the preparation method of diethylenetriamine-based low molecular weight 650 epoxy curing agent for epoxy polyamide coating, it comprises the following steps:

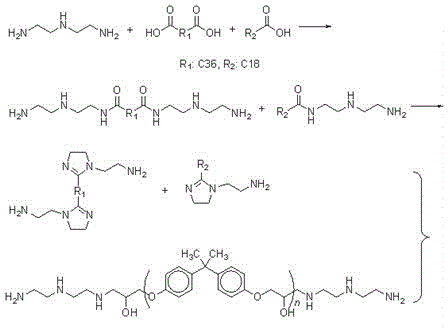

[0028] Such as figure 1 As shown, put 160g of diethylenetriamine, 280g of dimer acid and 141g of fatty monoacid into a 1000mL four-necked bottle, stir and heat, keep at 140oC for 2 hours, continue to heat to 160oC for 2 hours, continue to heat to 180oC to keep 2 hours, finally heat to 200oC and hold for 2 hours, then cool down to 160oC and put in 60g of liquid low-viscosity bisphenol A epoxy resin, then raise the temperature to 200oC and keep it for 1 hour, after vacuuming for 2 hours, cool down to 16...

Embodiment 2

[0031] 1. Diethylenetriamine-based low molecular weight 650 epoxy curing agent for epoxy polyamide paint, which is made of the following raw materials in parts by weight:

[0032] Diethylenetriamine 200g, dimer acid 340g, fatty monoacid 180g, bisphenol A epoxy resin 80g, phenol 20g, benzyl alcohol 20g, xylene 20g.

[0033] 2, the preparation method of diethylenetriamine-based low molecular weight 650 epoxy curing agent for epoxy polyamide coating, it comprises the following steps:

[0034] Put 200g of diethylenetriamine, 340g of dimer acid and 180g of fatty monoacid into a 1000 mL reactor in turn, stir and heat, keep at 140oC for 3 hours, continue heating to 165oC for 3 hours, continue heating to 185oC for 3 hours, Finally, after heating to 195oC and keeping it for 3 hours, cool down to 160oC and put 80g of liquid low-viscosity bisphenol A type epoxy resin into it, then raise the temperature to 200oC and keep it for 2 hours. Benzyl alcohol and 20g of xylene are obtained after...

PUM

| Property | Measurement | Unit |

|---|---|---|

| amine value | aaaaa | aaaaa |

| amine value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com