Fuzzing roller and preparation method thereof

A technology of raising roller and roller body, which is applied in coating, roughening, textile and paper making, etc., can solve the problems of long stop time of raising roller, heavy weight of raising roller, serious energy loss, etc. Strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

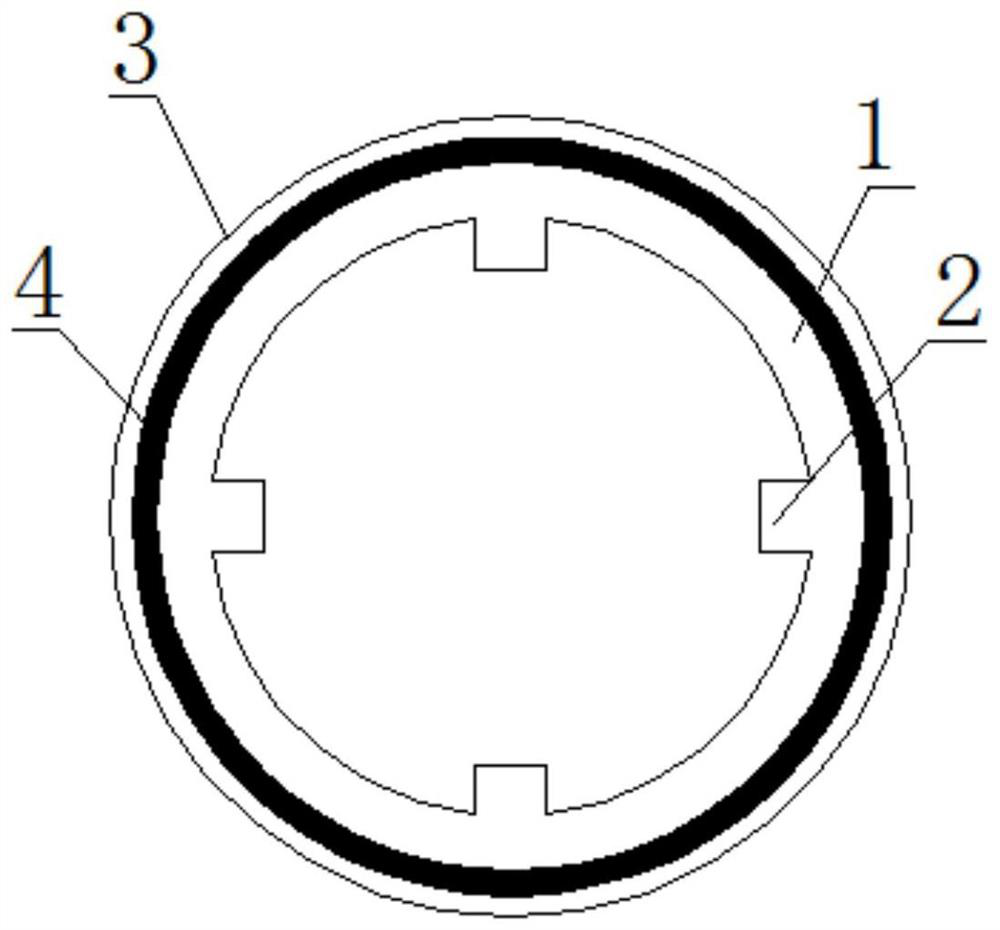

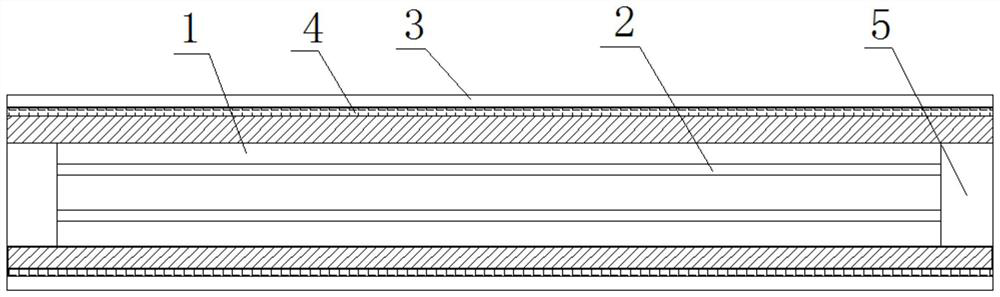

[0046] A fluffing roller, such as figure 1 , 2 As shown, the raising roller is a cylindrical hollow structure, and its structure includes a roller body 1 and fixing parts 5 at both ends;

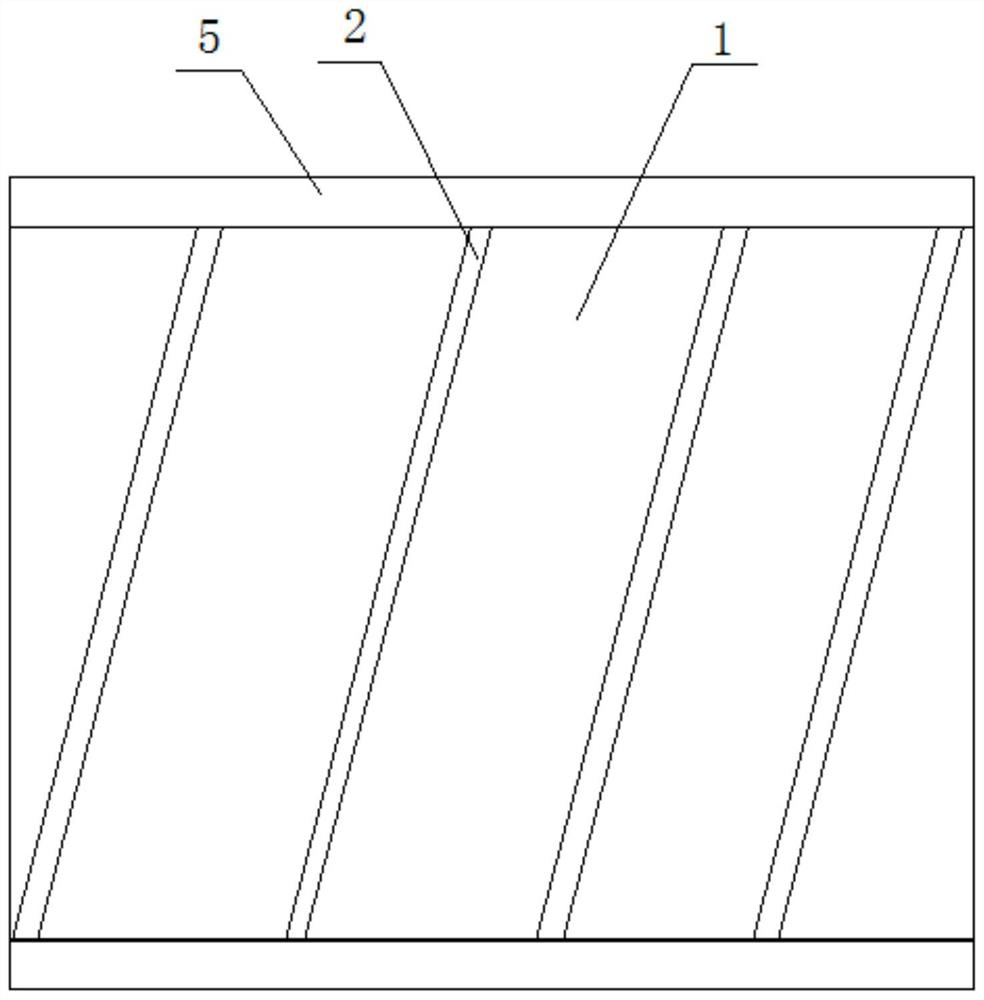

[0047] The inner wall of the roller body 1 is provided with several reinforcing ribs 2;

[0048] The reinforcing rib extends from one end of the inner wall of the roller body 1 to the other end of the inner wall of the roller body 1;

[0049] The bottom of the reinforcing rib 2 is connected to the inner wall of the roller body 1, and the top of the reinforcing rib 2 protrudes toward the axis of the roller body 2;

[0050] The inner wall of the fixing part 5 is a smooth cylindrical surface.

[0051] The intervals between the reinforcing ribs 2 in the roller body 1 are equal.

[0052] The shape of the cross-section of the reinforcing rib 2 is trapezoidal, wherein the side length of the bottom connected to the inner wall of the roller body 1 is longer than that of the top of the reinforcing...

Embodiment 2

[0064] A kind of raising roller preparation method, the realization process of described method comprises content as follows:

[0065] (1) Preparation of ribs 2 on the inner wall of the fluffing roller

[0066] Stamping the cylindrical blank of the raising roller to form reinforcing ribs on the inner wall;

[0067] (2) Processing of the inner wall of the fixed part 5 at both ends of the raising roller

[0068] Remove the reinforcing ribs on the inner wall of the fixing part 5 by grinding or grinding;

[0069] (3) Preparation of anti-skid coating

[0070] (4) Anti-slip coating 4 is coated on the outer surface of the raising roller;

[0071] (5) Fix the card clothing 3 on the outer surface of the raising roller coated with the anti-slip coating 4 .

[0072] The mesh number of the jade powder is 100-400 mesh.

[0073] The preparation process of described non-slip coating comprises content as follows:

[0074] (1) Screening the jade powder by 100-400 mesh;

[0075] (2) Sele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com