Polyester resin special for winding steel paint base and preparation thereof

A technology of polyester resin and primer, applied in polyester coatings, coatings, anti-corrosion coatings, etc., can solve the problems of limited processing performance of pre-coated coils, poor pertinence, and failure to achieve processing effects, etc., to achieve Ease of large-scale production, low requirements for production equipment, and high solid content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

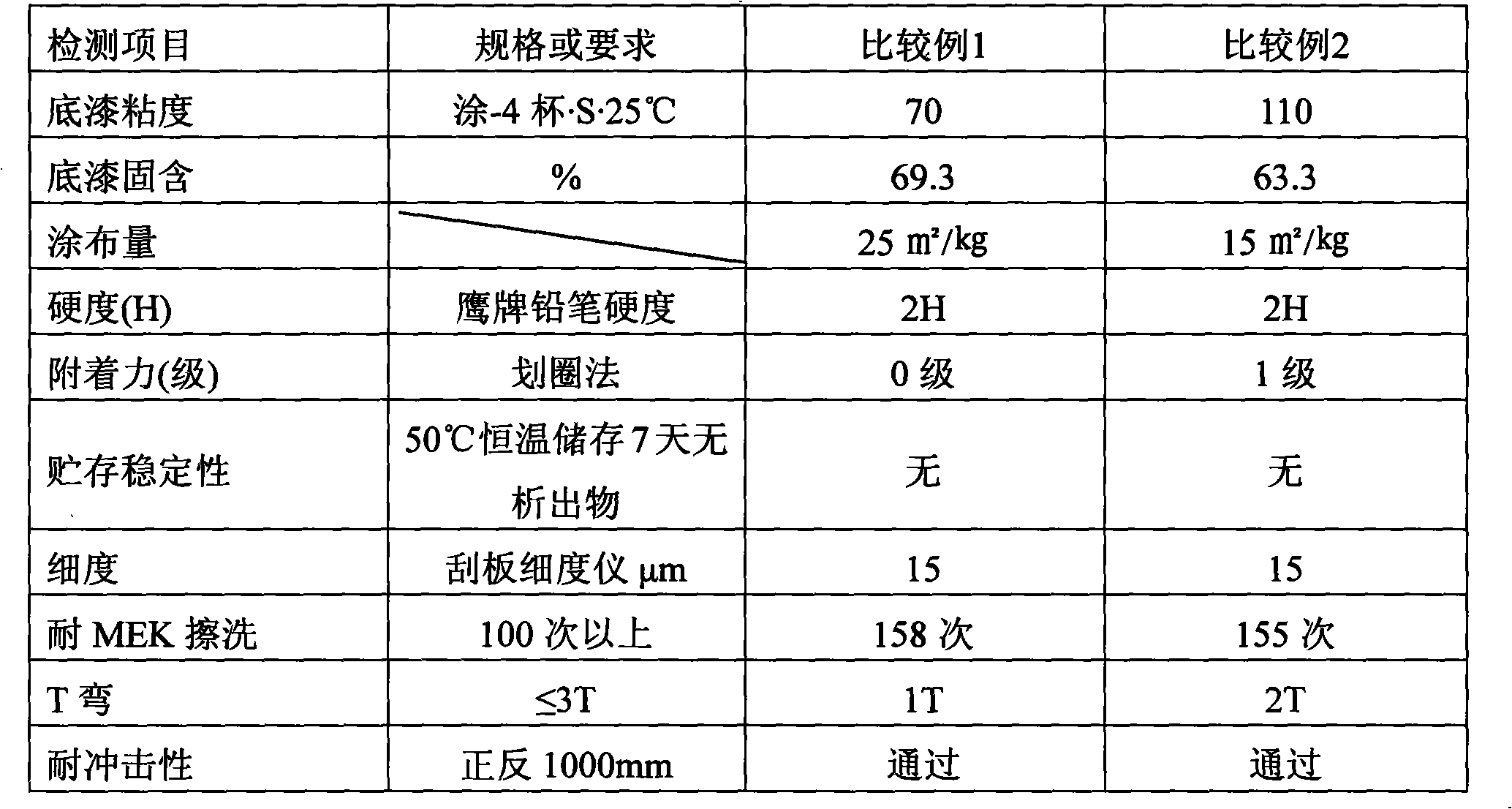

Examples

Embodiment 1

[0026] A special polyester resin for the primer in coil coatings, which comprises the following components in parts by weight:

[0027] 35 parts of ethylene glycol

[0028] 35 parts of terephthalic acid

[0029] Dibutyltin dilaurate 0.1 part

[0030] 3 parts xylene

[0031] 20 parts of ethylene glycol butyl ether.

[0032] The production method is as follows:

[0033] 1. Fill the reaction kettle with a stirrer, a thermometer (including two thermometers: one for measuring the liquid phase temperature, and one for measuring the gas phase temperature), a reflux condenser, and a water separator. Phthalic acid and catalyst dibutyltin dilaurate through N 2 Protection, start heating up. Start stirring intermittently when the material is 160°C, observe the material in the kettle until it is completely dissolved before starting the stirring formally. Control the temperature of the liquid material in the kettle between 150 and 250°C, and the temperature of the gas phase at 95°C a...

Embodiment 2

[0037] A special polyester resin for the primer in coil coatings, which comprises the following components in parts by weight:

[0038] Glycerin 40 parts

[0039] Trimellitic anhydride 40 parts

[0040] Dibutyltin diacetate 0.1 part

[0041] S-100# 3 copies

[0042] 20 parts of cyclohexanone.

[0043] The production method is as follows:

[0044] 1. Put glycerin, trimellitic anhydride and catalyst in a reaction kettle equipped with a stirrer, a thermometer (including two thermometers: one for measuring liquid phase temperature and one for measuring gas phase temperature), reflux condenser and water separator Dibutyltin diacetate, through CO 2 Protection, start heating up. Start stirring intermittently when the material is 160°C, observe the material in the kettle until it is completely dissolved before starting the stirring formally. Control the temperature of the liquid material in the kettle between 150 and 250°C, and the temperature of the gas phase at 95°C and 105°C...

Embodiment 3

[0048] A special polyester resin for the primer in coil coatings, which comprises the following components in parts by weight:

[0049] Pentaerythritol 30 parts

[0050] 30 parts of isophthalic acid

[0051] Monobutyltin oxide 0.1 parts

[0052] 3 parts xylene

[0053] 20 parts of n-butanol.

[0054] The production method is as follows:

[0055] 1. Fill the reaction kettle with a stirrer, a thermometer (including two thermometers: one for measuring the liquid phase temperature, and one for measuring the gas phase temperature), a reflux condenser, and a water separator with a formula amount of pentaerythritol and resorcinol. Formic acid and catalyst monobutyltin oxide, pass through N 2 Protection, start heating up. Start stirring intermittently when the material is 160°C, observe the material in the kettle until it is completely dissolved before starting the stirring formally. Control the temperature of the liquid material in the kettle between 150 and 250°C, and the tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com