Neoprene adhesive and preparation method thereof

A chloroprene adhesive and adhesive technology, used in chloroprene adhesives, adhesives, adhesive types, etc., can solve the problems of low product viscosity and easy delamination, and meet environmental protection requirements and high solid content. , good weather resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

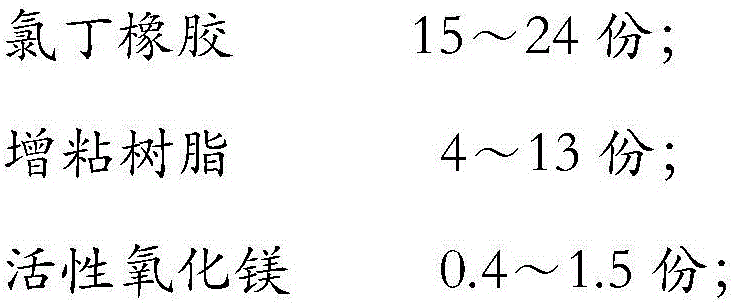

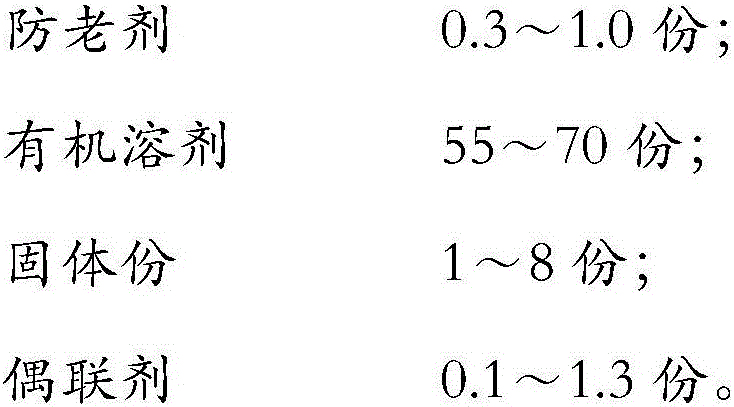

Method used

Image

Examples

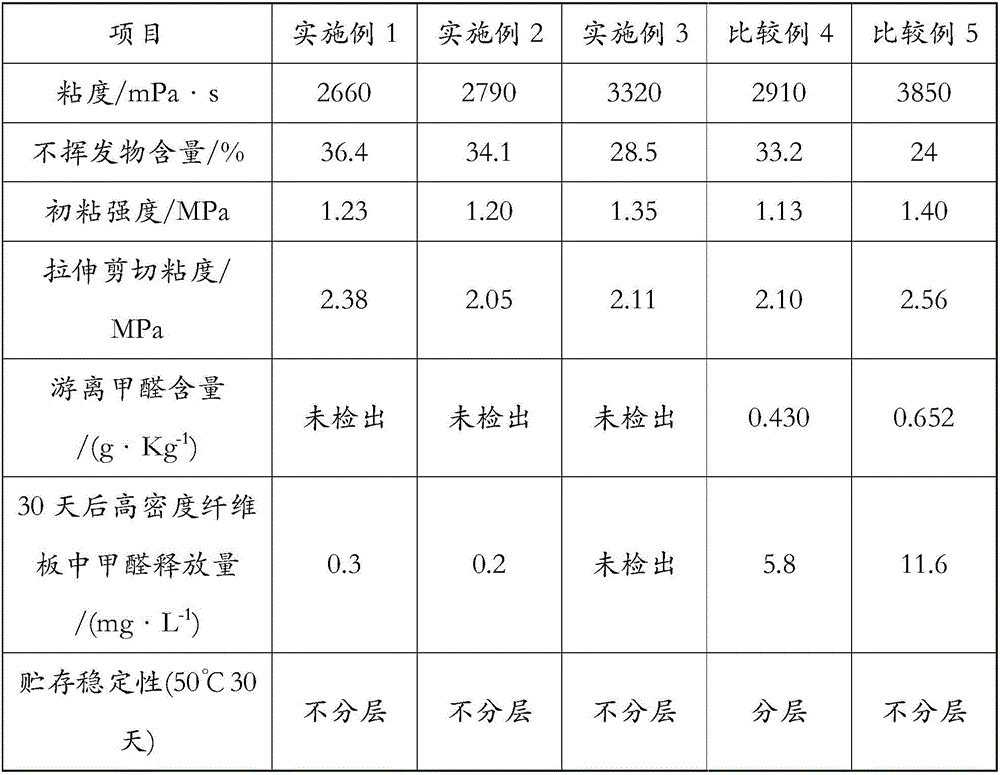

Embodiment 1

[0043] According to the formula weight ratio, take 2 parts of hydrogenated rosin, 2 parts of hydrogenated rosin glyceride and 24 parts of dimethylcyclohexane, 12 parts of methylcyclohexane, 10 parts of isopropyl acetate, dimethyl succinate 15.4 parts of organic solvents were mixed and stirred until completely dissolved; 1 part of precipitated silica and 7 parts of fumed silica, which had been baked at 120°C for 4 hours and cooled to room temperature, were mixed with N-2-(aminoethyl) -3 A coupling agent consisting of 0.05 parts of aminopropylmethyldimethoxysilane and 0.05 parts of γ-aminopropyltriethoxysilane is mixed, stirred evenly, and then added to an organic solvent; then 0.4 parts of activated magnesium oxide are added After mixing with 0.3 parts of anti-aging agent CTU, add 0.6 parts of formaldehyde absorbent (0.4 parts of menthol, 0.1 parts of tea polyphenols, 0.1 parts of XZ-FL2333 from Hefei Xiangzheng Chemical Technology Co., Ltd.); then add Shanxi synthetic rubber 1...

Embodiment 2

[0045] According to the formula weight ratio, dissolve 3 parts of hydrogenated rosin glyceride, 2 parts of hydrogenated terpene resin, and 2 parts of hydrogenated C9 resin into 24 parts of methylcyclohexane, 20 parts of isopropyl acetate, and dimethyl succinate 20 parts of organic solvent; then add 5 parts of fumed silica which was baked at 140°C for 2 hours and cooled to room temperature, and N-2-(aminoethyl)-3 aminopropylmethyldimethoxy Stir 0.25 parts of silane and 0.25 parts of γ-aminopropyltriethoxysilane; then add 1 part of active magnesium oxide, 0.4 parts of N-octyl-N'-phenyl-p-phenylenediamine, hydroxy-N-benzene Base-p-phenylenediamine zinc salt 0.1 part after mixing evenly, add 1.2 parts of formaldehyde absorbent (0.6 part of menthol, 0.2 part of tea polyphenol, 0.1 part of citrus essential oil, 0.3 part of nano-anion powder of Shijiazhuang Dianshi Hengcheng Nano Material Co., Ltd. parts); add 5 parts of NEC A30, 4 parts of NEC M40, and 12 parts of Baypren320, stir a...

Embodiment 3

[0047] According to the formula weight ratio, dissolve 13 parts of hydrogenated terpene resin into an organic solvent composed of 20 parts of dimethylcyclohexane, 36 parts of methylcyclohexane and 10.6 parts of isopropyl acetate; Baked for 1 hour and cooled to room temperature with 0.5 parts of precipitated silica, 0.5 parts of fumed silica, and 0.7 parts of N-2-(aminoethyl)-3 aminopropylmethyldimethoxysilane and γ - Stir 0.6 parts of aminopropyltriethoxysilane; then add 1.5 parts of active magnesium oxide, 0.3 parts of anti-aging agent N-hydroxy-styrenated diphenylamine-methyl phenyl ketone, N-sec-octyl-N' -0.3 parts of phenyl-p-phenylenediamine, 0.1 part of hydroxyl-N-phenyl-p-phenylenediamine zinc salt, 0.3 parts of anti-aging agent CTU and mix well, add 1.0 parts of formaldehyde absorbent (0.4 parts of menthol, 0.15 parts of citrus essential oil Parts, 0.45 parts of Baohua negative ion powder of Shenzhen Baohua negative ion powder Co., Ltd.); Add 15 parts of neoprene Baypr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com