Rod milling method and device

A rod mill and rod mill technology, applied in grain processing and other directions, can solve the problems of low overflow discharge output, low overall efficiency, and difficult load adjustment, and achieve the effects of easy operation, improved efficiency, and easy shutdown.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

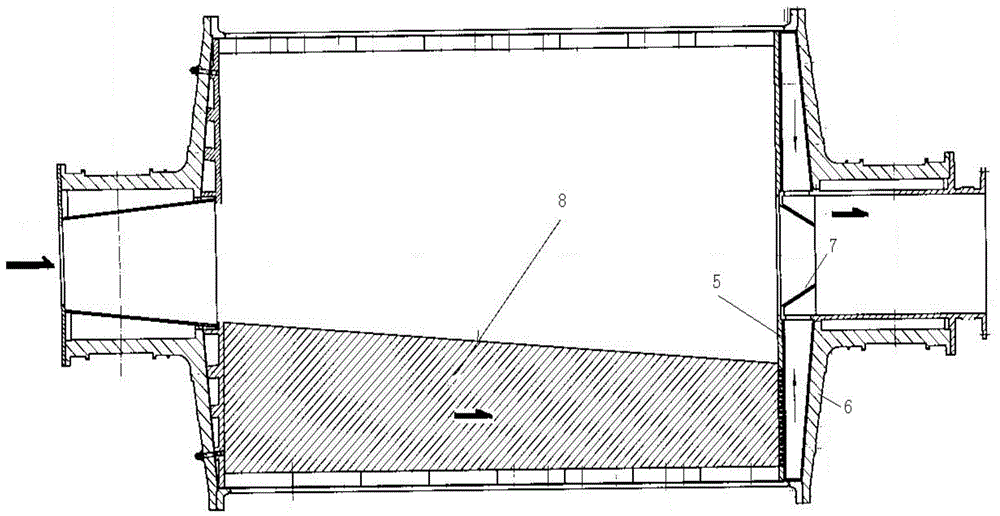

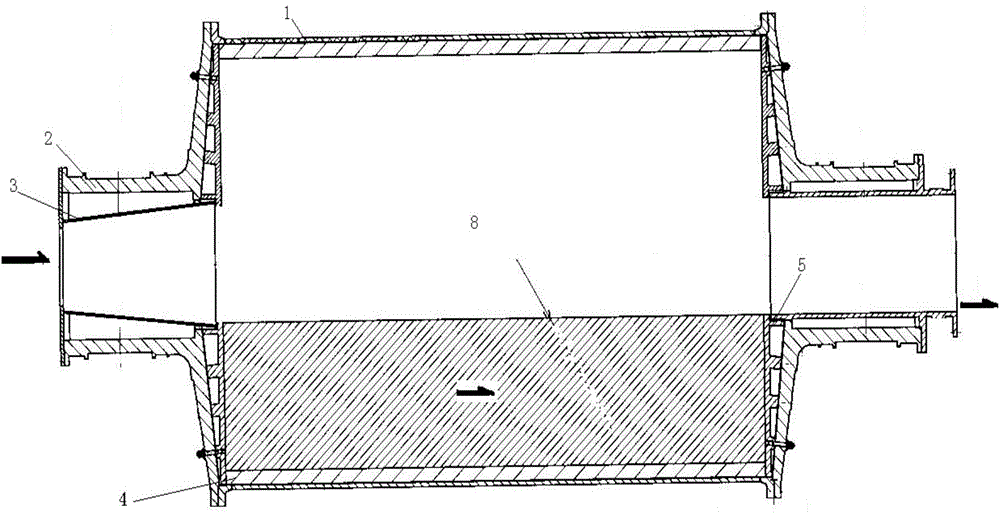

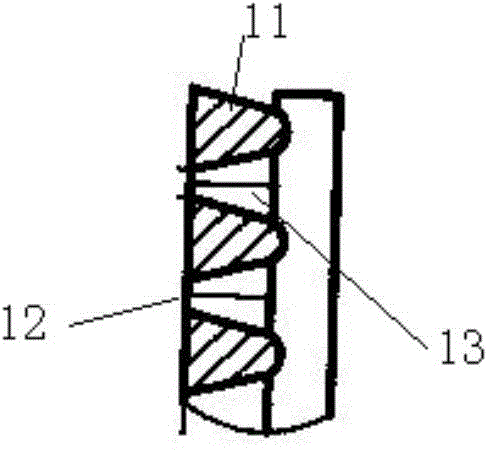

[0026] The rotary part, the rotary part is a cylinder 1 rolled and welded by steel plate, the two ends are respectively connected with the hollow shafts of the inlet and outlet with bolts, and are supported horizontally on the two main bearing bushes. The hollow shaft 2 is equipped with a feeding screw cylinder or other feeding cylinders 3 . The rotary part is rotated by the pinion gear through the large ring gear at one end of the fixed cylinder with the help of a reducer and a motor. A liner 4 is provided inside the cylinder, which not only protects the cylinder but also brings the steel rod to a suitable height to improve the efficiency of rod milling. In order to prevent dust and water leakage from the bolt holes of the liner, the bolts of the liner should be wrapped with a sealing device close to the outer wall of the cylinder. The barrel is equipped with a manhole door, which is used for repairing and replacing the internal parts of the whole body by unloading the grind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com