System and method for improving slurry property of low order coal slurry

A technology of coal-water slurry and low-rank coal, which is applied in the system field of improving the slurryability of low-rank coal-water slurry, and can solve the problem of affecting cold gas efficiency, high coal consumption and oxygen consumption of coal-water slurry gasification, and low-concentration water-coal Increase transportation cost of pulp and other problems, achieve the effect of saving transportation cost, improving pulping performance, and small equipment modification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

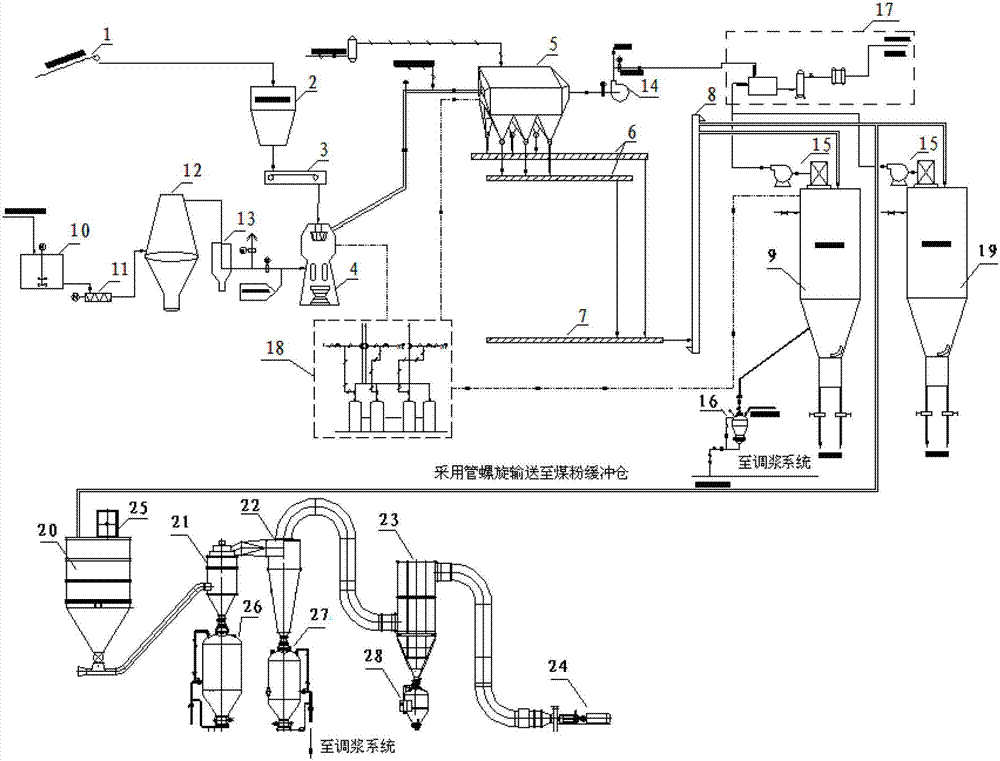

[0045] Such as figure 1As shown, the equipment of the present invention includes a pulverizing system and a fine powder separation system. In the pulverizing system, a coal conveying belt 1 is included to transport raw coal through a bin belt conveyor. The coal conveying belt 1 is connected to a buffer bin 2, and the buffer bin 2 passes through The weighing coal feeder 3 is connected to the vertical mill 4, and the vertical mill 4 is connected to a vertical mill drying mechanism. The above-mentioned equipment constitutes two sets of vertical mill mechanisms, and the two sets of vertical mill mechanisms can respectively pulverize raw coal. Grinding and fine grinding. The vertical mill 4 is connected to the 1# pulse bag dust collector 5, and the 1# pulse bag dust collector 5 is connected to the large screw feeder 7 through the small screw feed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com