Vicinal diol functionalized macroporous through-hole material as well as preparation method and boric acid adsorption application thereof

A technology of vicinal diols and functionalization, which is applied in chemical instruments and methods, adsorption water/sewage treatment, inorganic chemistry, etc., to achieve acid-base stability, facilitate later removal, and avoid consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) Add sodium dodecylbenzenesulfonate (0.14g, 0.4mmol) to an aqueous solution of polyethyleneimine (20wt.%, 2ml, pH 9.1), stir and mix;

[0029] (2) Add microcrystalline cellulose (0.2 g) to the system. The mixture was shaken on a shaker at 1000 rpm for 10 minutes to form an air-in-water emulsion.

[0030] (3) Add polyethylene glycol diglyceryl ether liquid (0.5 g, molecular weight 500, 1 mmol) into the emulsion, and continue shaking for 5 minutes. The mixture was left at room temperature for 6 hours.

[0031] (4) Vacuum treatment with a water pump at 60°C. After about 1.6mL of water is removed, the porous solid is taken out, cut into small pieces (about 2 mm square), immersed in NaOH (5%) aqueous solution (15mL), stirred gently, and removed. Wash with water once.

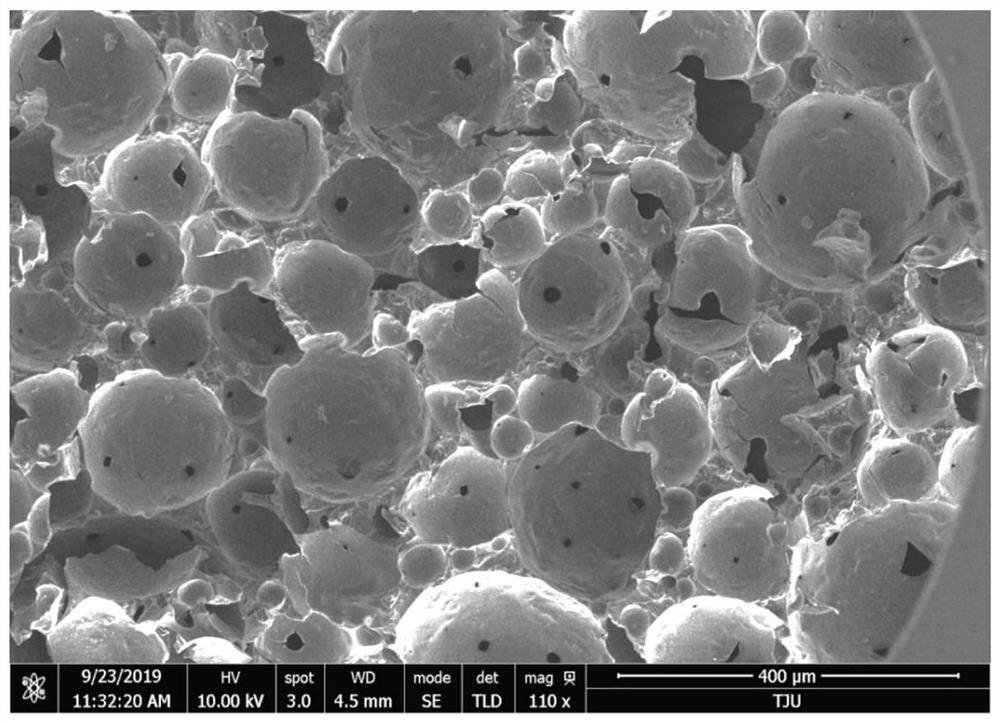

[0032] (5) The solid was immersed in an ethanol solution (20 mL) of glycidyl ether (3 g, 40 mmol), and stirred gently at 50° C. for 12 hours. Take out and dry. figure 1 It is a scanning electron micros...

Embodiment 2

[0035] In Example 1, linear polyethyleneimine was used instead of branched polyethyleneimine, and the pH was also adjusted to 9.1. The viscosity of the system is higher and the emulsion is more stable. The boron adsorption amount of the corresponding porous adsorbent is 33 mg (boron element) / g.

Embodiment 3

[0037] In embodiment 1, replace sodium dodecylbenzene sulfonate with stearic acid (or lauric acid, or sodium lauryl sulfate) of the same quality, and similar porous adsorbent is also obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com