Aminopolycanboxylic acid porous material as well as preparation method and application thereof

A technology of amino polycarboxylic acid and porous material, which is applied in the field of amino polycarboxylic acid porous material and its preparation, and achieves the effects of stable chemical structure, high mechanical strength and easy separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

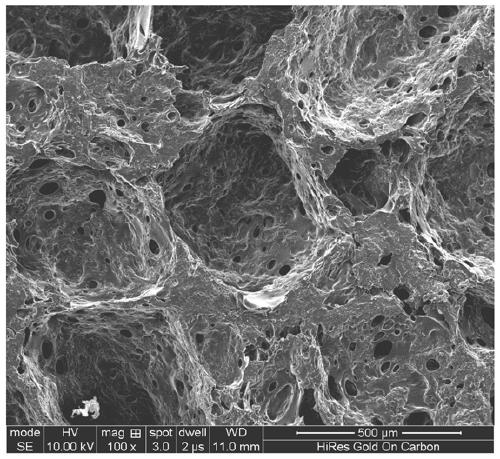

Image

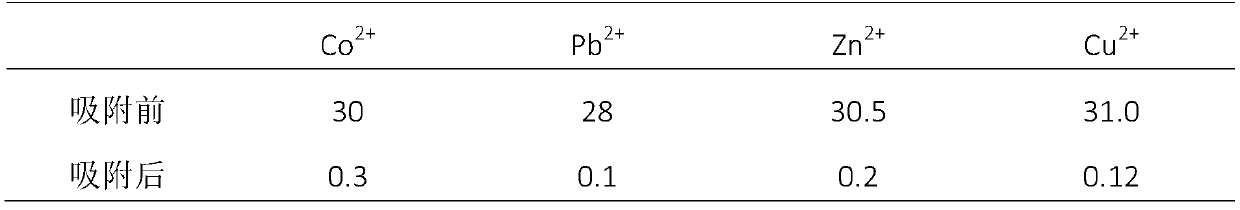

Examples

preparation example Construction

[0037]

[0038] A kind of preparation method of amino polycarboxylic acid porous material, it comprises the steps:

[0039] (1) Disperse the rigid particles in an aqueous solution of polyethyleneimine, adjust the pH value to 10.5-12.5, add the oil phase under stirring, and obtain an oil-in-water emulsion;

[0040] (2) After adding a cross-linking agent into the oil-in-water emulsion, continue to stir for 1-3 minutes, and stand at 0-90°C for 6-48 hours to solidify; use ethanol to perform Soxhlet extraction and then vacuum-dry, or carry out cross-linking Add cyclohexane to the final system for azeotropic dehydration, then carry out distillation and deoiling, and then carry out vacuum drying to obtain a porous material;

[0041] (3), put the porous material into the aqueous solution of haloacetic acid (the amount is 1-3 molar equivalents of residual amino hydrogen), add a buffer solution with a pH value of 7-9, or continuously add sodium carbonate solution, dilute hydrogen Sod...

Embodiment 1

[0065] The preparation method of the amino polycarboxylic acid porous material of the present embodiment comprises the steps:

[0066] (1), adding silicon dioxide (particle size is 100 μm, 0.18g) to branched polyethyleneimine (M n =60000, 0.1g / mL, 3mL) in the aqueous solution, stir and disperse, adjust the pH value to 11, under vigorous stirring, add cyclohexane (6mL) dropwise to the aqueous dispersion, and drop it within 10min to obtain water Oil-in-emulsion;

[0067] (2), then add polyethylene glycol diglyceryl ether (M n =500, 0.87g, 0.25 equivalent of NH), continue to stir for 1min, and stand to solidify at 25°C for 6h; add 20mL cyclohexane to the system, then heat to reflux and separate most of the water with an oil-water separator, and then The cyclohexane was evaporated, and the remaining solid was vacuum-dried to obtain a porous material;

[0068] (3), get chloroacetic acid (1.485g, 15.7mmol) and dissolve in the phosphate buffer (0.2mol / L, 40mL), drop into the porou...

Embodiment 2

[0070] Same as Example 1, but with the same weight of microcrystalline cellulose instead of silicon dioxide particles, the amino polycarboxylic acid porous material is similarly obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Surface area | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com