Dewatering apparatus and oil-water cyclone separator of pipe type distributor oil-water separator

A technology of oil-water separator and deflector, which is applied in the direction of the device, the swirl device, the separation method, etc. where the axial direction of the swirl flow remains unchanged, and can solve the fluctuation of the operating parameter inlet condition, limit the processing capacity, and the outflow of the oil phase and other problems, to achieve the effect of improving oil-water separation efficiency, good adaptability, and small space occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

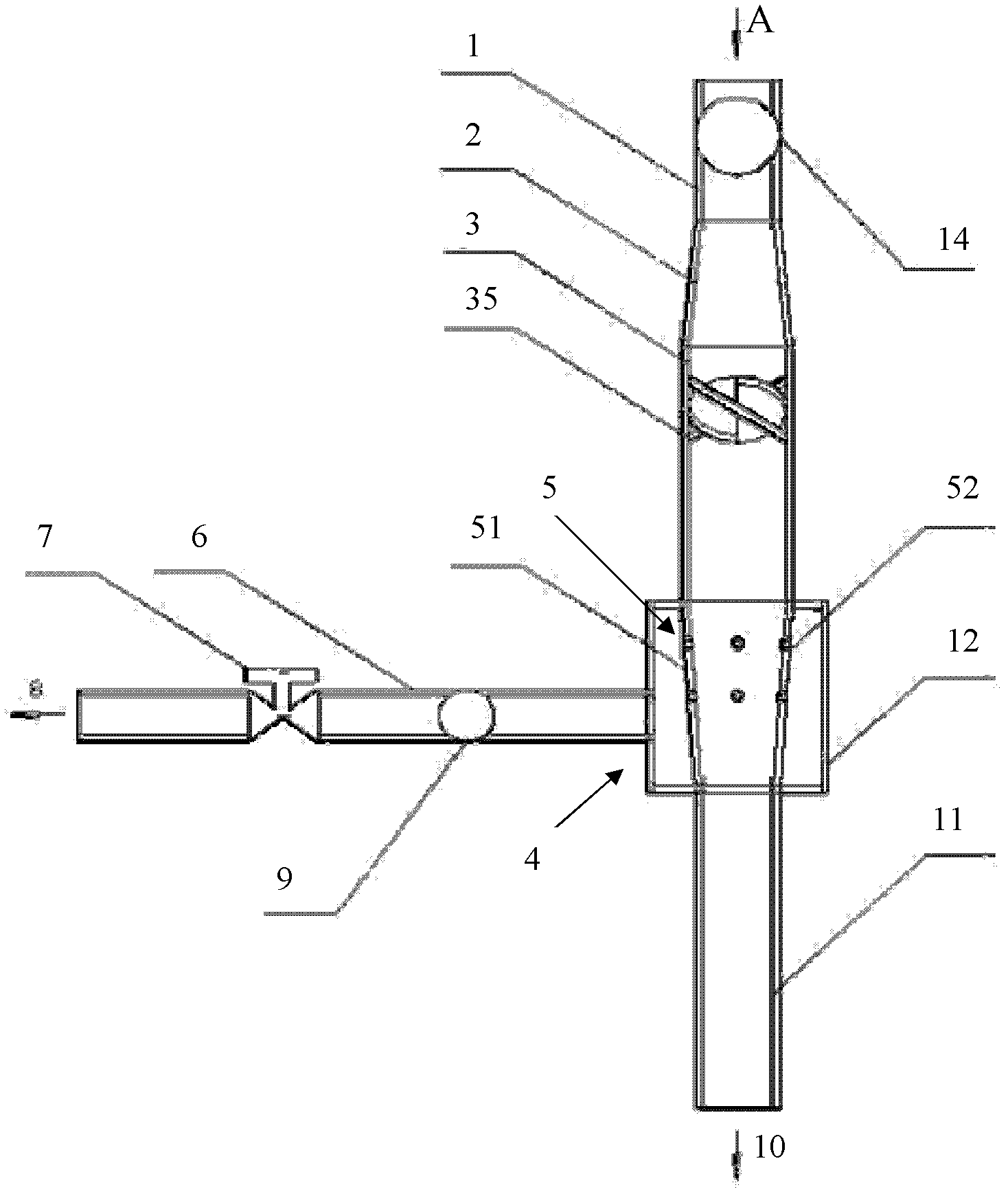

[0028] like figure 1 As shown, the present invention includes: the liquid inlet pipe section 1, the gradual expansion pipe section 2, the swirl flow generation pipe section 3 and the gradual water removal pipe section 5 connected in sequence, because the inner diameter of the swirl flow pipeline of the swirl flow generation pipe section 3 is larger than the liquid inlet pipe section The inner diameter of the pipeline of 1, therefore, the expanding pipe section 2 is set between the liquid inlet pipe section 1 and the swirl flow generation pipe section 3, and a flow meter 14 is installed on the liquid inlet pipe of the liquid inlet pipe section 1.

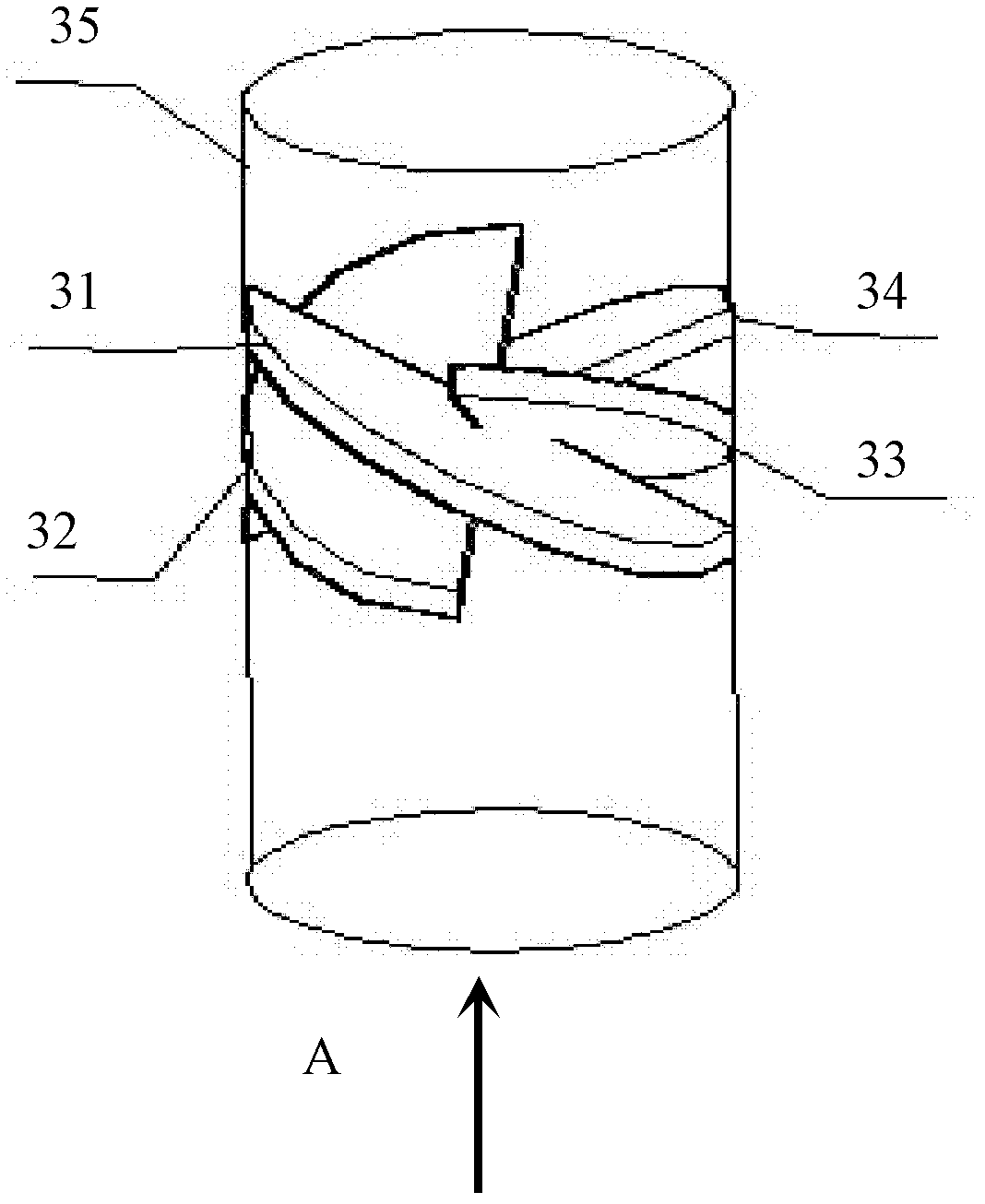

[0029] like Figure 2~3 As shown, the swirl generation pipe section 3 further includes 4 deflectors 31, 32, 33, 34 that can be fixedly and obliquely installed in the swirl pipe 35, and the deflectors 31, 32, 33, 34 are along Evenly distributed in the circumferential direction, and stacked in sequence in the axial direction of the sw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com