A corrugated steel wall with dissipative corners

A technology of corrugated steel plates and corners, which is applied to walls, building materials, building components, etc., can solve problems such as stress concentration, failure, tearing of non-buckling corrugated steel plate energy-dissipating walls, etc., to achieve earthquake energy dissipation, small size, Effect of improving deformation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to facilitate the understanding of those skilled in the art, the structure of the present invention will be further described in detail with the embodiments in conjunction with the accompanying drawings:

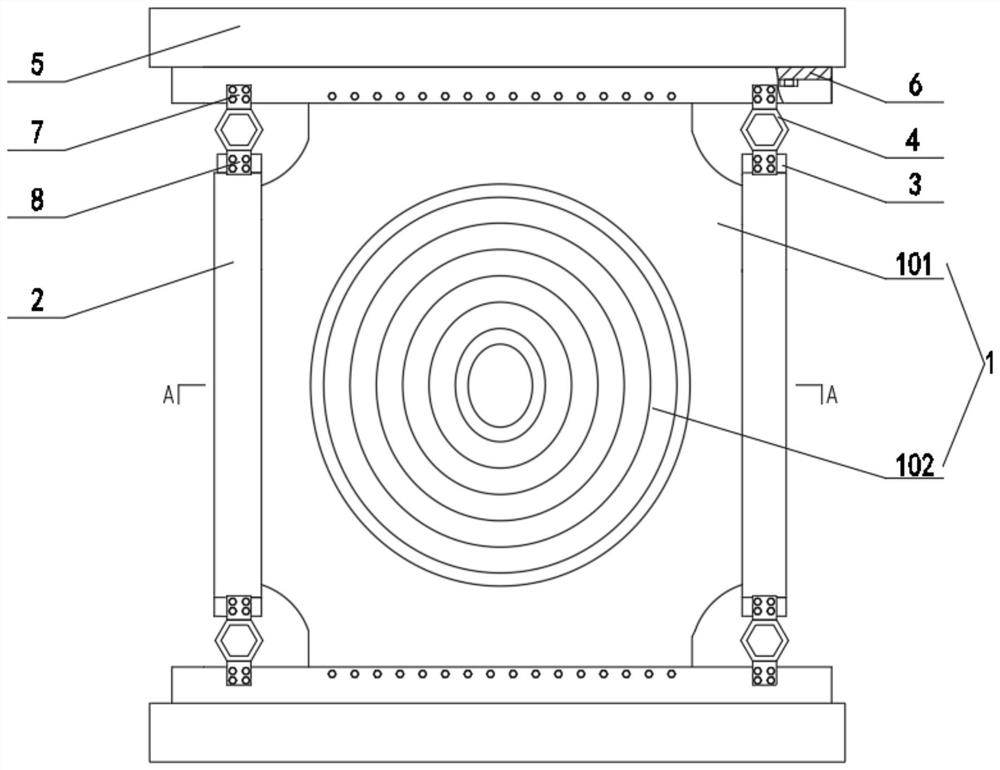

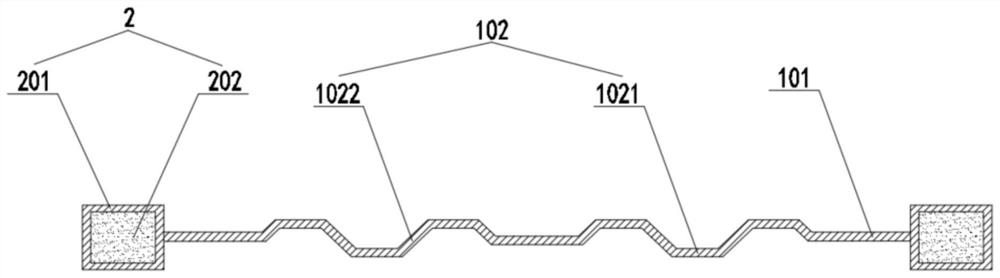

[0019] refer to Figure 1-2 , a corrugated steel plate wall that can consume energy at the corner, including a corrugated steel plate wall 1, the corrugated steel plate wall 1 is composed of an integrally formed peripheral plane steel plate 101 and a central corrugated steel plate 102 (the peripheral plane steel plate in this embodiment 101 and the central corrugated steel plate 102 can be formed by integrated casting), and the corrugated track of the central corrugated steel plate 102 is a regular elliptical shape. If the corrugated trajectory of the central corrugated steel plate 102 is set in a regular elliptical shape, the buffering effect between the corrugations can still allow proper deformation to consume external forces. The most important thing is t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com