Hermetic type compressor

A compressor, airtight technology, applied in the direction of compressors, refrigerators, mechanical equipment, etc., can solve the problems of enhanced environmental impact, high risk of fire and explosion, waste of refrigerator oil, etc., to achieve less refrigerator oil and less dangerous The effect of small, low amount of refrigerant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

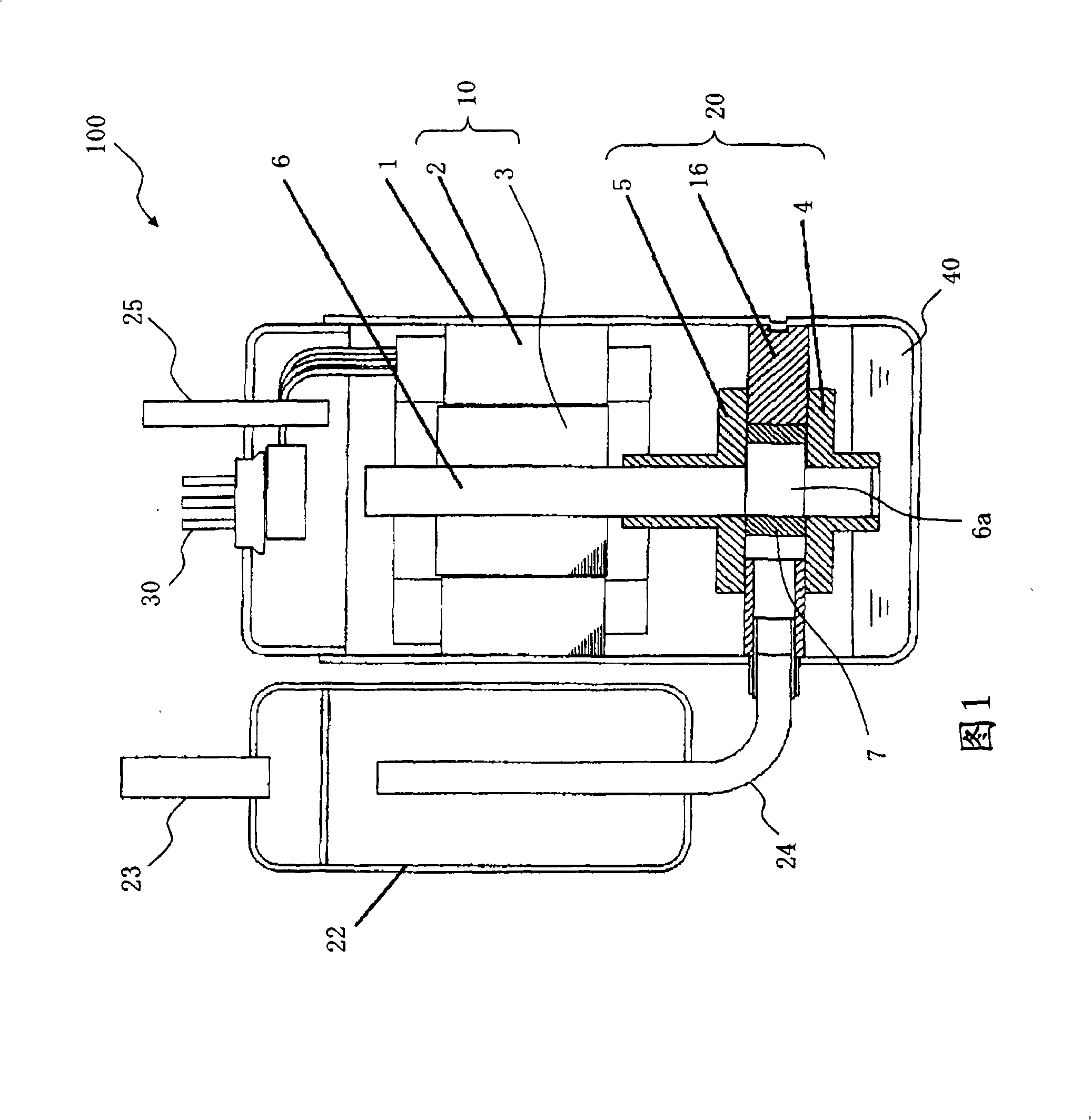

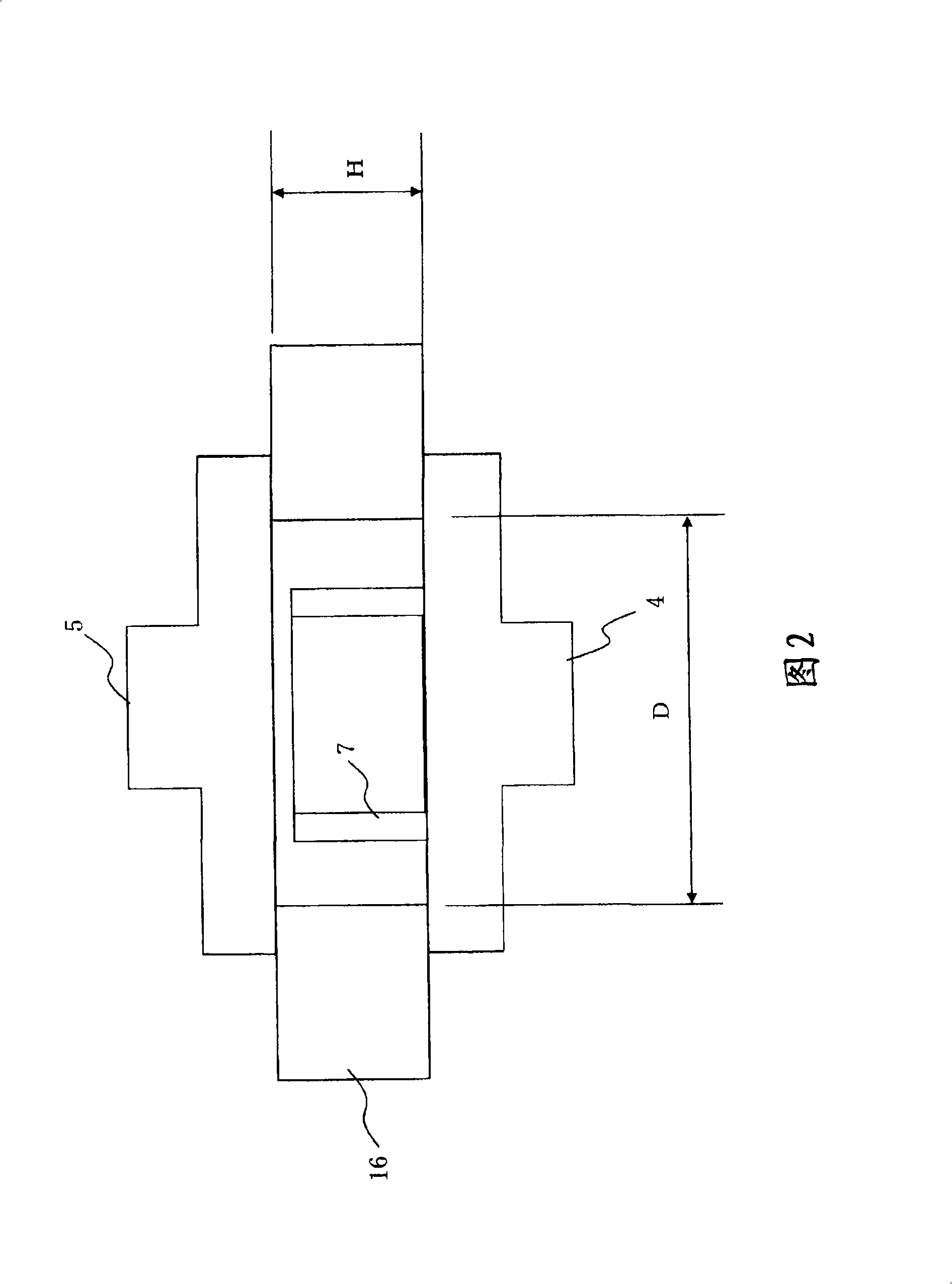

[0023] figure 1 , figure 2 is a drawing showing Embodiment 1, figure 1 is a longitudinal sectional view schematically showing the hermetic compressor 100, figure 2 It is a longitudinal sectional view of main parts of the hermetic compressor 100 .

[0024] refer to figure 1 The structure of the hermetic compressor 100 will be described. The hermetic compressor 100 will be described using a rotary compressor as an example. However, it is also applicable to scroll compressors other than rotary compressors. The hermetic compressor 100 houses a compression mechanism unit 20 and a motor 10 that drives the compression mechanism unit 20 in a hermetic container 1 .

[0025] The motor 10 has a stator 2 and a rotor 3 rotating inside the stator 2 . Electric power is supplied to the stator 2 from the glass terminal 30 . The motor 10 generally uses a brushless DC motor, an induction motor, or the like.

[0026] The compression mechanism part 20 has the cylinder 16, and the outer...

Embodiment approach 2

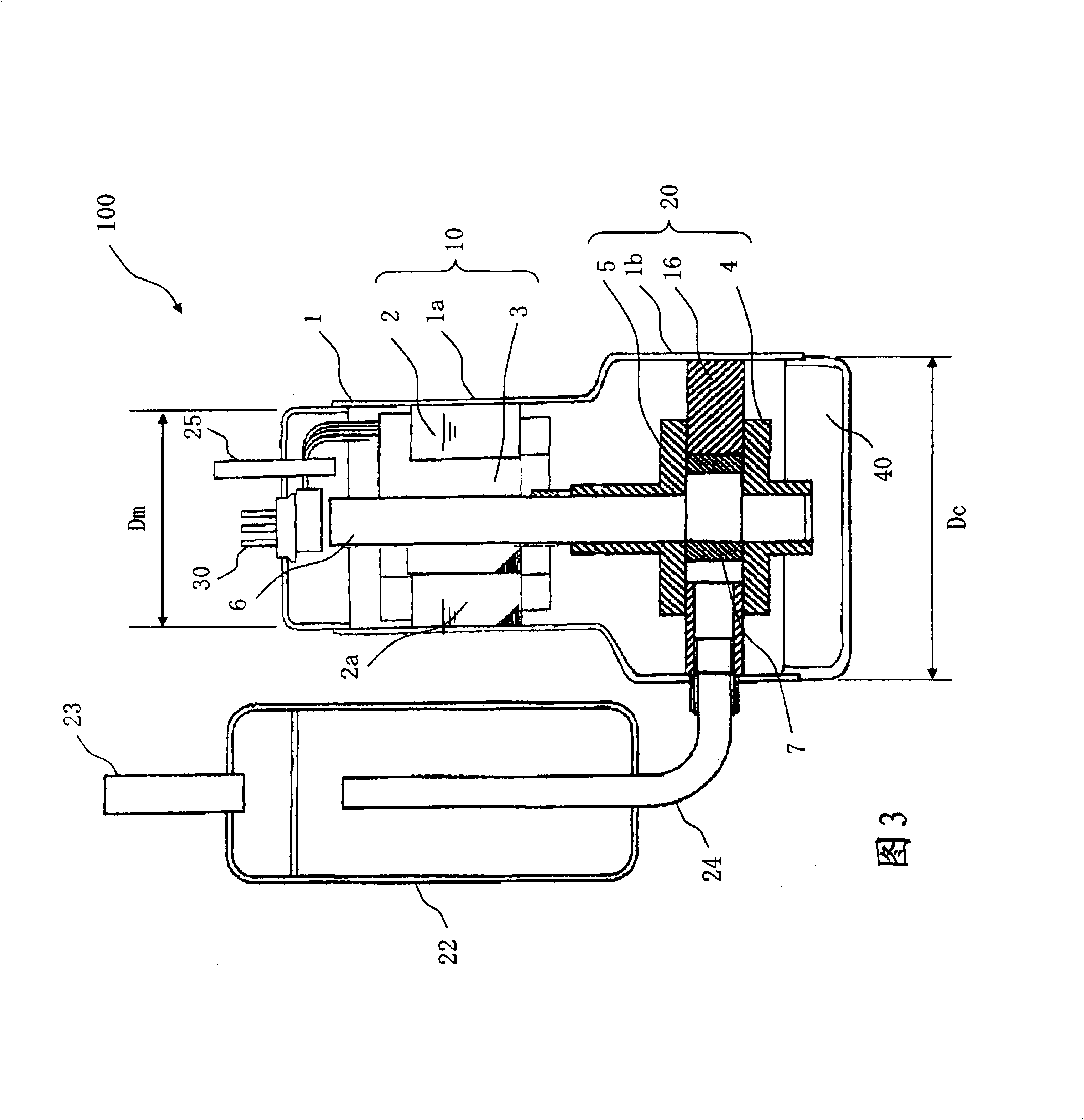

[0042] image 3 It is a drawing showing Embodiment 2, and is a longitudinal sectional view schematically showing a hermetic compressor 100 .

[0043] image 3 The structure of the shown hermetic compressor 100 is the same as that of figure 1 The hermetic compressor 100 is the same.

[0044] (1) The outer diameter Dm of the motor 10 is made smaller than the outer diameter Dc of the compression mechanism part 20 .

[0045] (2) Accordingly, the inner diameter of the portion 1 a covering the motor 10 of the airtight container 1 is smaller than the inner diameter of the portion 1 b covering the compression mechanism portion 20 of the airtight container 1 .

[0046] The motor 10 is fitted and fixed to the inner periphery of the airtight container 1 by caulking or the like.

[0047] Here, the output of the electric motor 10 of the hermetic compressor 100 will be described. In a normal hermetic compressor 100 , the refrigerant changes due to constraints of production equipment, ...

Embodiment approach 3

[0056] In Embodiment 2, the outer diameter Dm of the motor 10 was made smaller than the outer diameter Dc of the compression mechanism part 20, but in this embodiment, the core 2a of the motor 10 is made The width (length in the axial direction) of the motor 10 is smaller than that of the core 2a of the motor 10 set for conventional refrigerants such as R410A, and the volume of the core 2a used in the motor 10 is reduced to adjust the output of the motor 10. Along with this, the height of the airtight container 1 covering the motor 10 is also reduced. Accordingly, the internal volume of the airtight container 1 is reduced.

[0057] It is assumed that the output of the motor 10 is proportional to the volume of the core 2a (the entirety of the stator and the rotor). The outer diameter of the motor 10 is made constant. Since the outer diameter of the motor 10 is constant, the core width H of the motor 10 can also be reduced to 0.9H when the output that the motor 10 must generat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com