Reel material strip marking method

A reel and tape technology, which is applied to record carriers, instruments, computer parts, etc. used in machines, can solve problems such as the inability to meet industrial production requirements, and achieve the effect of convenient labeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

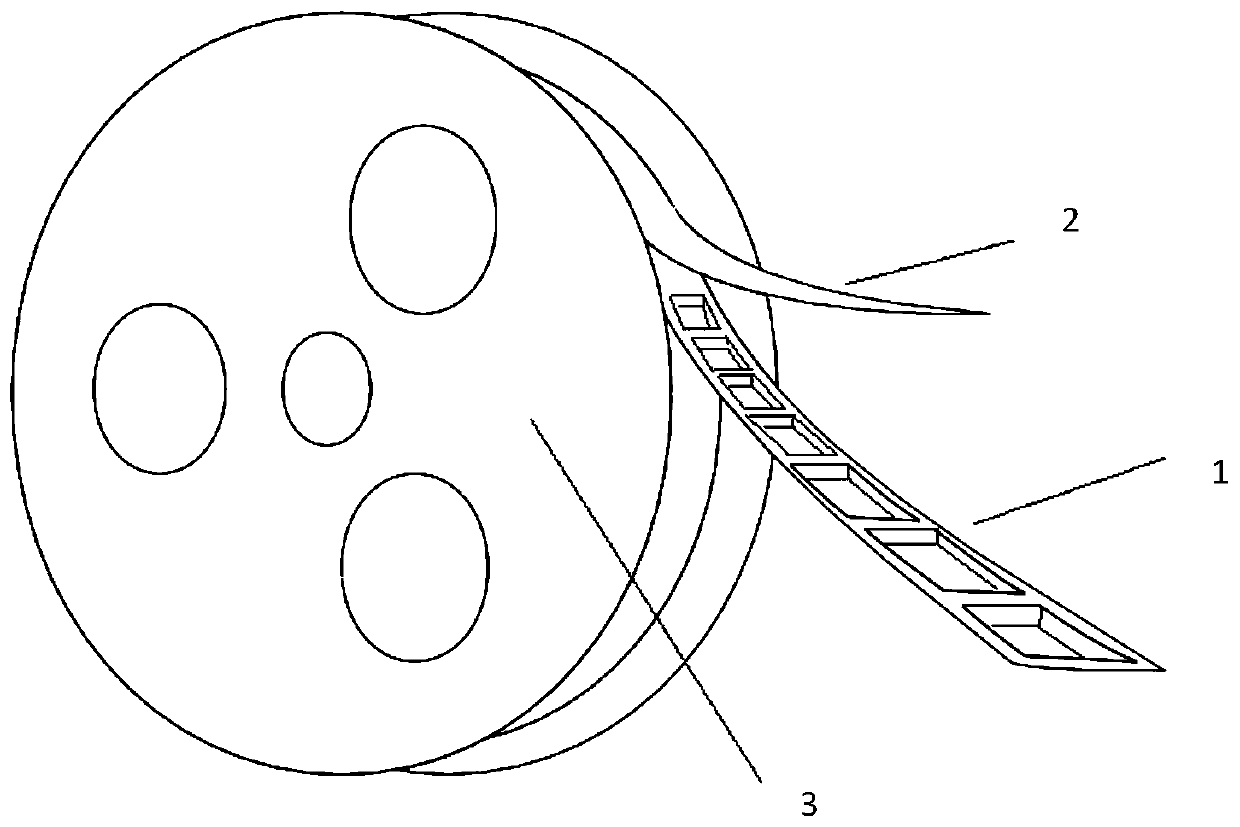

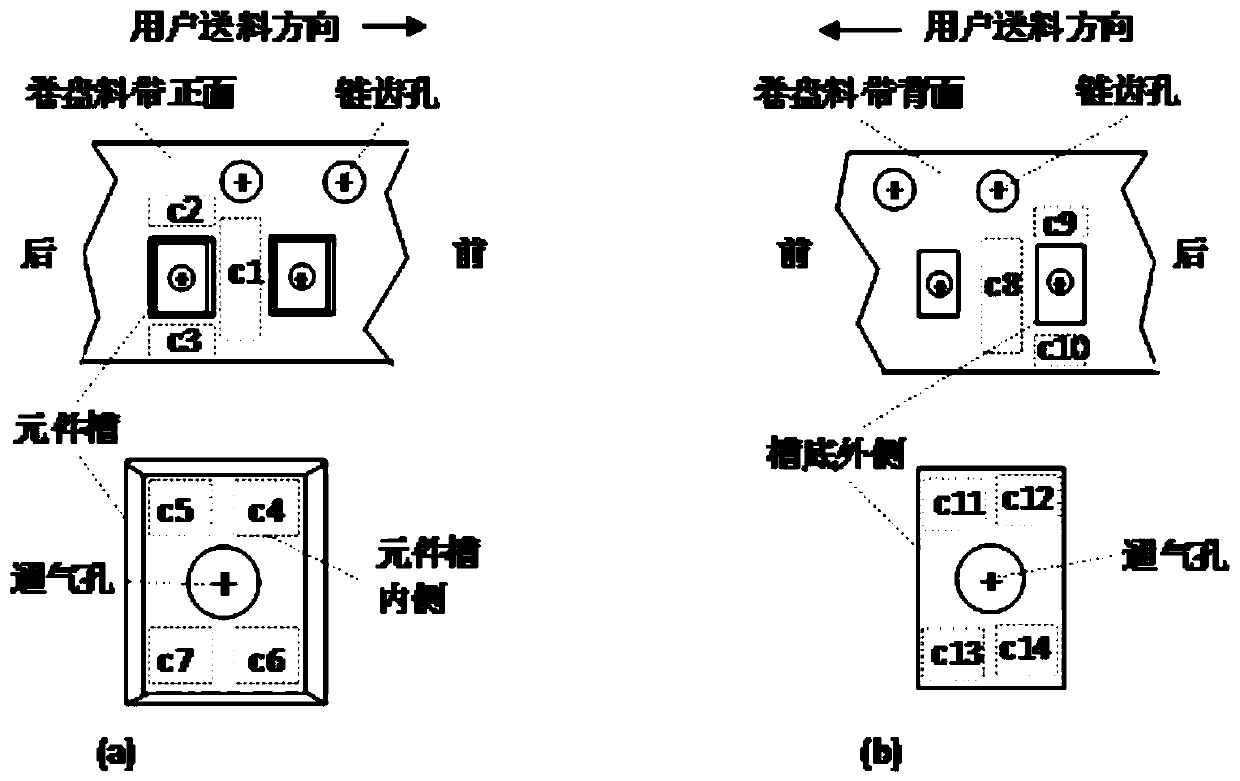

[0017] The invention realizes the unique identification of each device on the reel mainly by adding a graphic code on the carrier tape. For the convenience of description, the method of placing components on the material tape is taken as an example of a grooved material tape. When a component is placed in a fixed position of the device, such as figure 2 When it is in the slot shown, the serial number of this slot becomes the serial number of the component. A serial number occupies one or more adjacent component slots and surrounding planes. By reading these serial number codes, the unique serial number of each component slot in the reel is realized.

[0018] image 3 12 planar unit optio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com