Monitoring system and monitoring method for soot on boiler convection heating surface

A monitoring system and heating surface technology, applied in the direction of boiler working status indication, etc., can solve the problems of shortened life expectancy of heating surface, frequent soot blowing, and aggravated dust pollution on the heating surface, so as to achieve safe operation, ensure normal operation, and avoid accidents. The effect of a furnace shutdown accident

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The invention provides a boiler convection heating surface dust monitoring system and monitoring method. The present invention will be further described below in conjunction with the accompanying drawings.

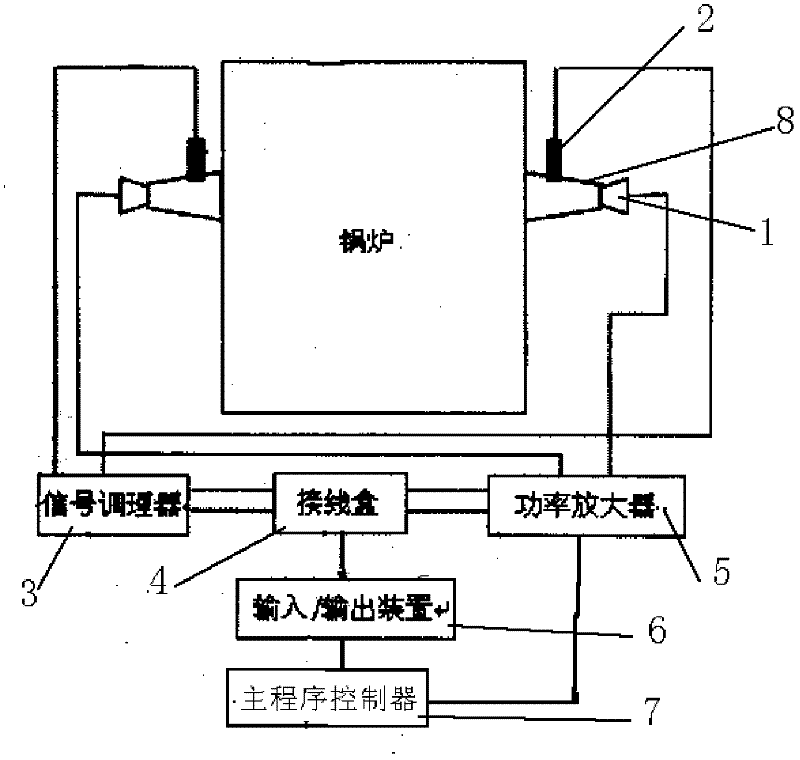

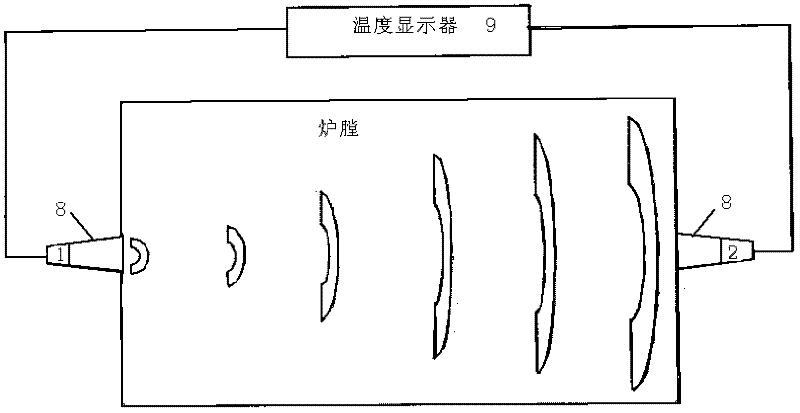

[0029] Schematic diagram of the structure of the novel dust monitoring device on the convection heating surface of the boiler as shown in the present invention figure 1 As shown, multiple pairs of sound wave generators 1 and sound wave receivers 2 are installed on the sound wave guides 8 at the corresponding positions around the water wall of the boiler. The signal output of the sound wave receivers 2 is connected to the signal conditioner 3, and the signal conditioner 3 is connected to the junction box 4 are connected by data lines, and the junction box 4 is connected to the host program controller 7 through the input / output device 6 . The host program controller 7 transmits the generated sound wave signal to the sound wave generator 1 through the power amplifier ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com