Berry fruit vibration harvesting device with branch supporting function

A vibrating device and berry technology, which is applied to picking machines, harvesters, agricultural machinery and implements, etc., can solve the problems of large damage to fruiting branches, difficulty in controlling the damage rate, and high operating costs, and achieve a large adjustment range and ensure the harvesting rate , the effect of reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

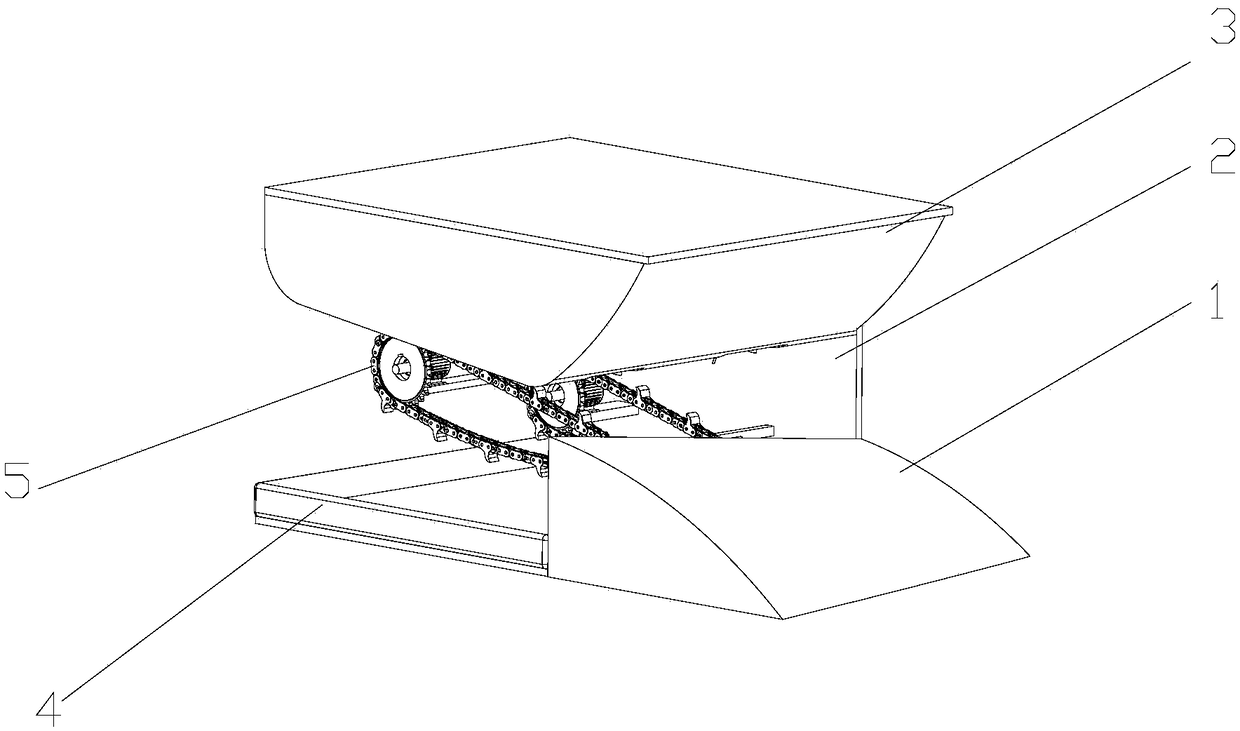

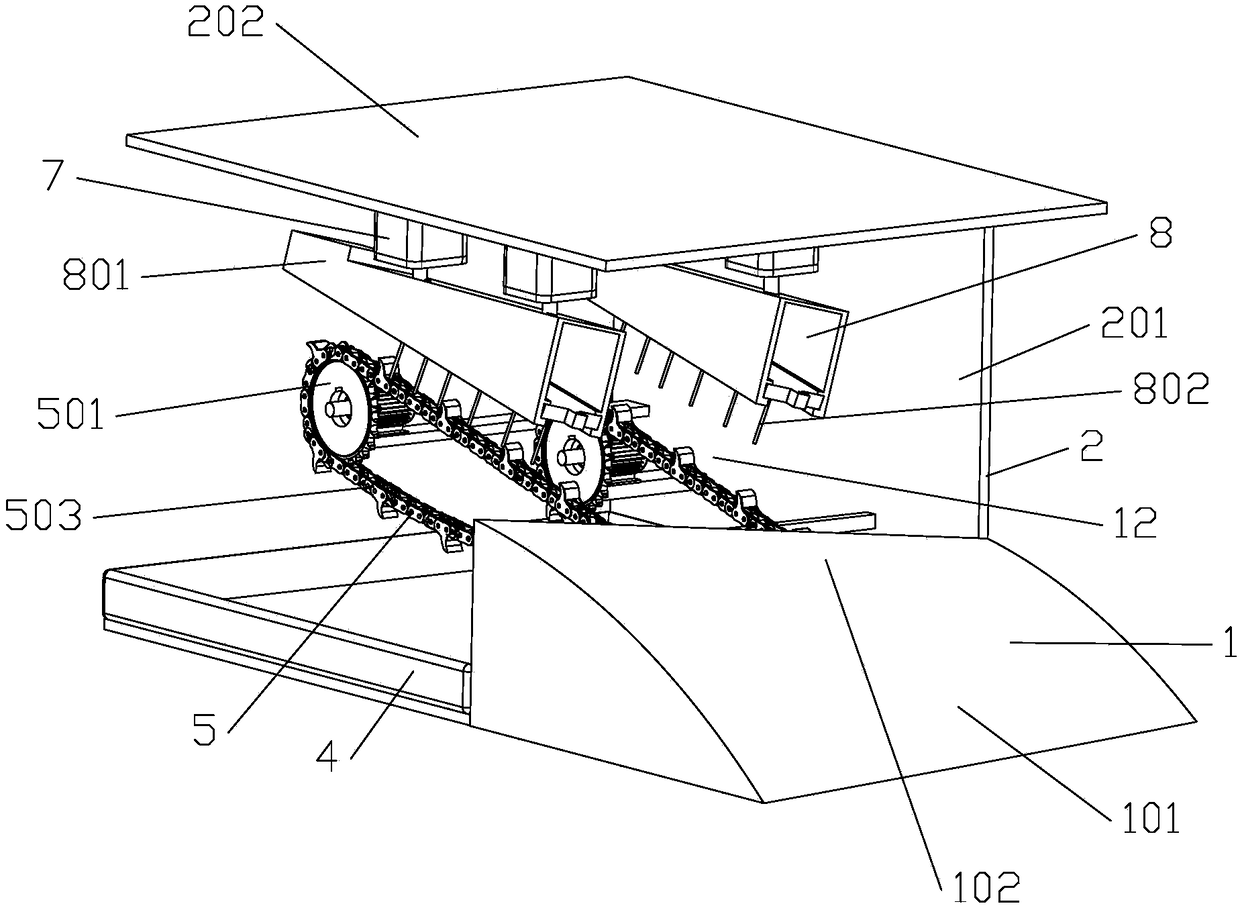

[0026] see figure 1 , 2 As shown, the vibrating harvesting device for berry fruits with the function of supporting branches includes: a guide plate 1, a frame 2 (including a fixed vertical plate 201 and a top plate 202 ), a skin 3, and a collecting device fixed on the right side of the lower part of the vertical plate. Box 4, branch holding device 5, cylinder 7, gear shaping vibration device 8.

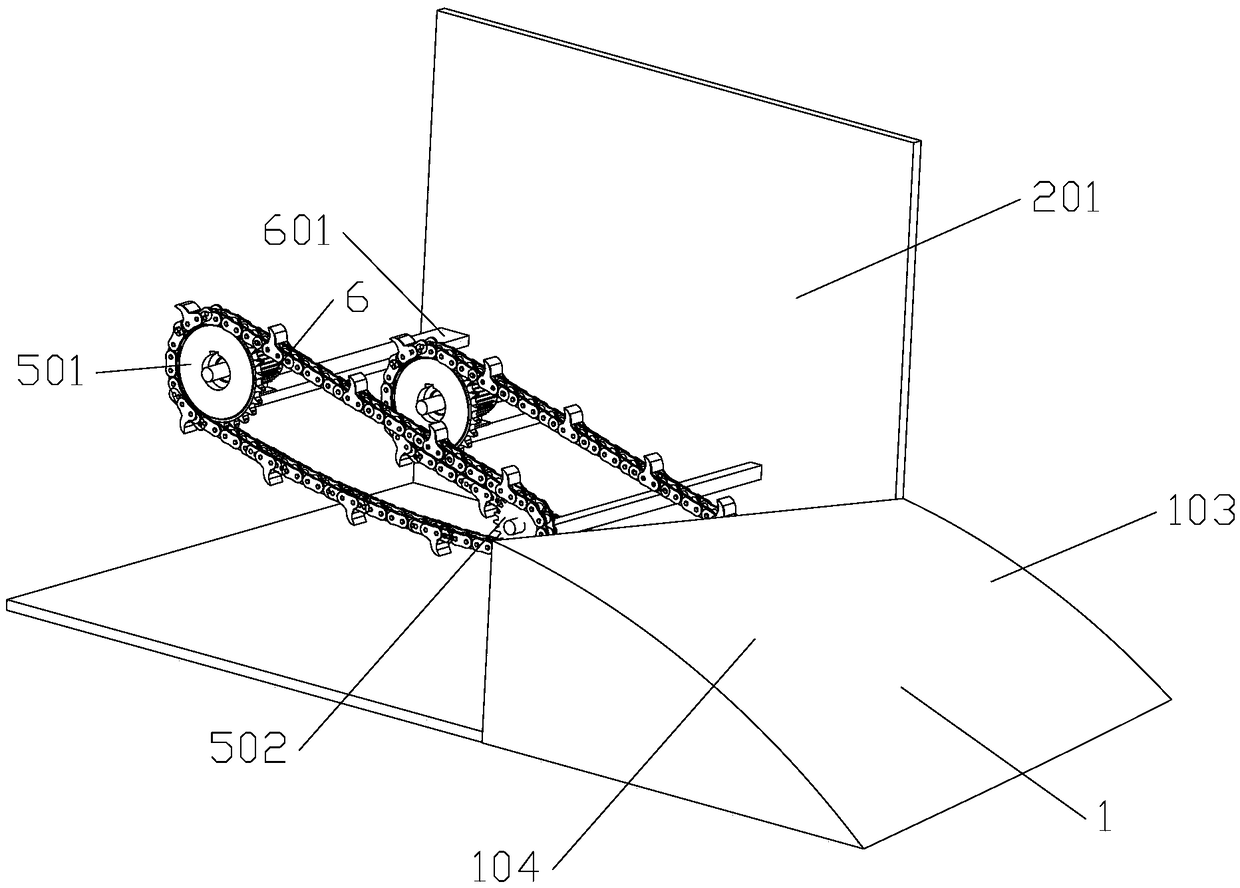

[0027] see image 3 , 4 , The branch holding device 5 includes a chain 503, a large sprocket 501, a small sprocket 502, a branch conveying drive motor 6, a support arm 601 fixed on the right side of the vertical plate, and the like.

[0028] see Figure 4 , 5 The gear shaping vibration device 8 includes a gear shaping guide rail 801, a gear shaping 802, a tooth shaping fixed plate 803, and a vibration mechanism 9 (including a connecting rod 901, a crank 902, and a horizontal drive motor 10 fixed on the tooth shaping fixed plate 803).

[0029] see Figure 6, when using this berr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com