Sewage treatment system for constructional engineering

A sewage treatment system and construction engineering technology, which is applied in the field of sewage treatment systems for construction engineering, can solve the problems of poor sedimentation effect of construction engineering sewage and poor sedimentation efficiency, and achieve the effect of preventing accumulation and increasing sedimentation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

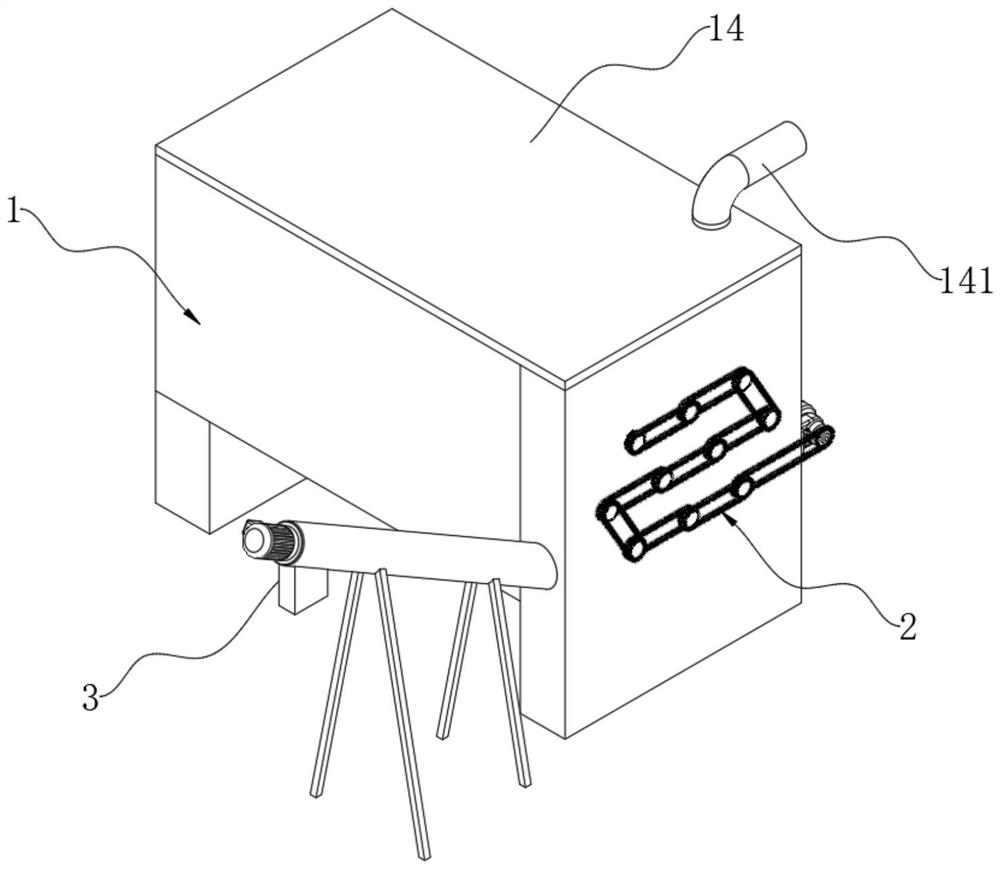

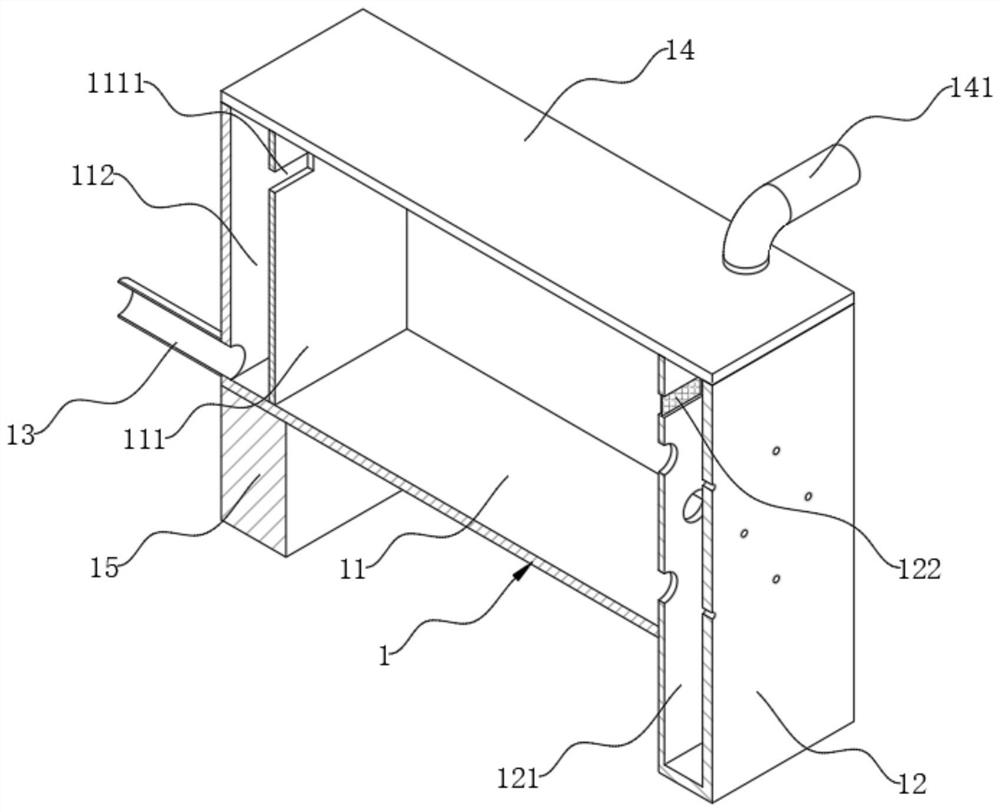

[0030] refer to Figure 1-Figure 8 , the sewage treatment system for construction engineering of the present invention comprises a treatment box 1, a settling chamber 11 is provided in the treatment box 1, a concentration bin 12 is arranged at the front end of the treatment box 1, and the rear end surface of the treatment box 1 is connected with The liquid outlet pipe 13, the top of the processing box body 1 is fixed with a top cover 14 by bolts, the top edge of the top cover 14 is connected with a liquid inlet pipe 141, and the end of the liquid inlet pipe 141 stretches into the bottom of the sedimentation chamber 11, by The sewage produced by the construction project is passed into the liquid inlet pipe 141 so that the sewage can be injected into the sedimentation chamber 11 so that the sewage can be settled in the sedimentation chamber 11 . The rear side of the sedimentation chamber 11 is tightly welded with a partition 111, and the top of the partition 111 is provided with...

Embodiment 2

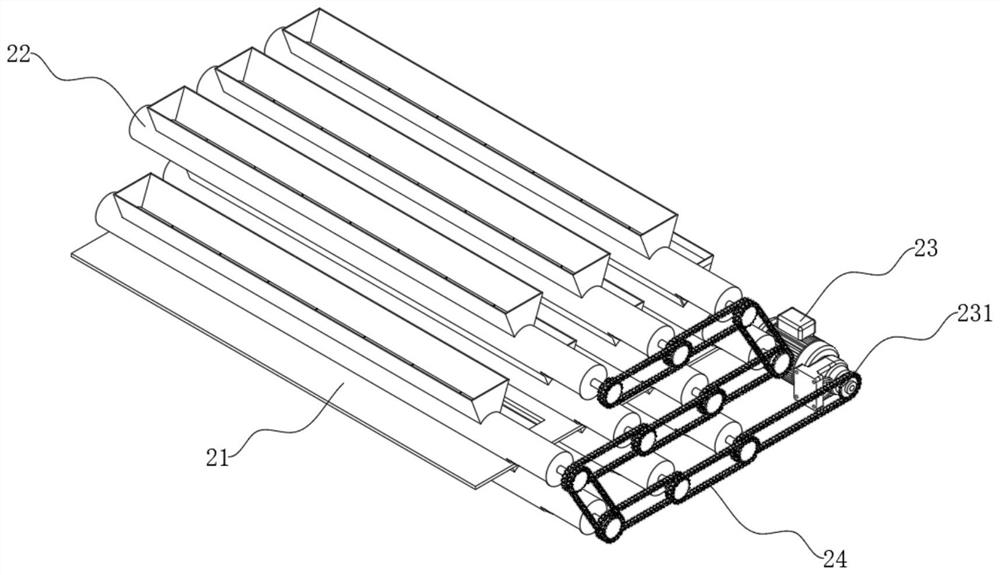

[0036] In the above scheme, a sediment discharge structure 3 is installed on the centralized bin 12, and the sediment discharge structure 3 includes a fixed sleeve 31 tightly welded on the left end surface of the centralized bin 12, a pocket plate 32 tightly welded in the concentrated bin 12, and a sleeve. The major axis 33 is arranged in the fixed sleeve 31 .

[0037] In this embodiment, the fixed sleeve 31 communicates with the inside of the centralized warehouse 12, and the top end of the fixed sleeve 31 is tightly welded with an end sleeve 311, which is hollow and communicates with the inside of the fixed sleeve 31, and the periphery of the fixed sleeve 31 Several supporting legs 312 are tightly welded on the surface, and a helical blade 331 is tightly welded on the peripheral surface of the major axis 33. The top end of the long axis 33 in the plate 32 is coaxially connected with a conveying motor 332 , and the conveying motor 332 is fixed on the top surface of the fixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com