Overwinding buffer and tank supporting device for elevating systems of mine vertical shaft and hydraulic system

A technology of lifting system and buffer hydraulic cylinder, applied in elevators, transportation and packaging, etc., can solve the problems of plastic deformation of steel strip, unusable, unreliable tank support, etc., and achieves small over-roll collision impact, stable buffer braking force, stable buffer braking force, etc. The effect of short fall distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with accompanying drawing, specific embodiment of the present invention will be further described:

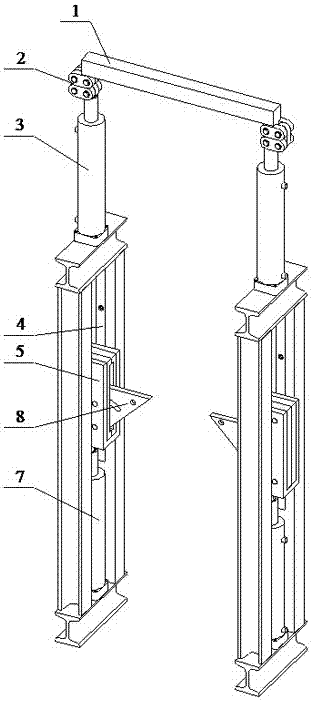

[0025] The mine vertical shaft hoisting system over-rolling buffer support tank device and hydraulic system of the present invention, such as figure 1 As shown, the mine vertical shaft hoisting system over-rolling buffer support tank device is composed of a beam buffer part, a hydraulic tank support part, and a hydraulic buffer system; the beam buffer part is fixed above the derrick, and the hydraulic tank support part is fixed below the beam buffer part derrick.

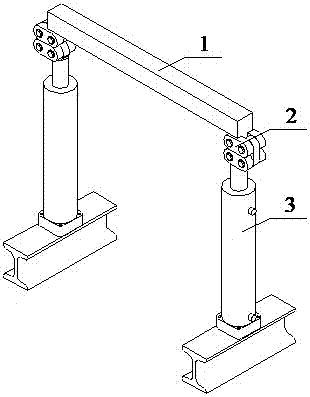

[0026] The beam cushioning part, such as figure 2 As shown, it includes a buffer hydraulic cylinder 3 fixed on the derrick and a beam 1 above it. The top of the piston rod of each buffer hydraulic cylinder 3 is respectively hinged to the lower ends of the beam 1 through three buffer chain links 2 .

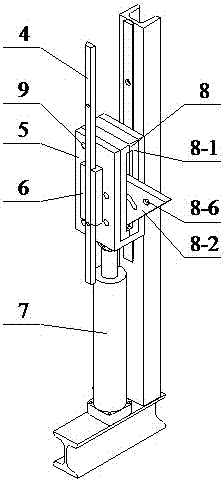

[0027] The hydraulic tank part, such as image 3 As shown, it includes a tank support ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com