Activated carbon static sorting device

A sorting device and activated carbon technology, applied in the field of separation, can solve problems such as segregation, unstable air flow, activated carbon dust and small particles with small specific gravity, and reduced adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

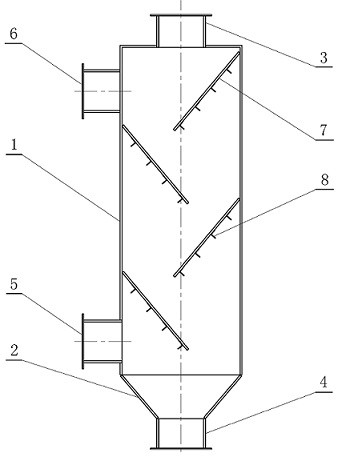

[0019] In order to solve the problems in the background technology, the invention provides an activated carbon static separation device, which is used to separate the dust and small particles in the activated carbon. This device sorts the activated carbon through the action of wind. During the sorting process, the activated carbon is not impacted and will not cause secondary fragmentation of the activated carbon; and the sorting process is carried out in a closed space, which will not cause secondary dust pollution.

[0020] see figure 1 , the present invention includes a vertical sorting drum and a plurality of guide chutes 7 . Among them, the vertical sorting cylinder is connected by upper and lower sections, the upper section is the straight section 1 of the sorting cylinder, the lower section is the cone section 2 of the sorting cylinder, the top of the straight section 1 of the sorting cylinder is provided with a feed port 3, and the side wall The lower end is provided w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com