Sheet material cutting stacking apparatus and sheet material cutting stacking method

A lamination device and sheet technology, applied in the cutting of textile materials, tools for sewing clothes, textiles and papermaking, etc., can solve the problems of separation of undisclosed clothing pieces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0095] Examples for carrying out the invention are shown below.

[0096] 【Example】

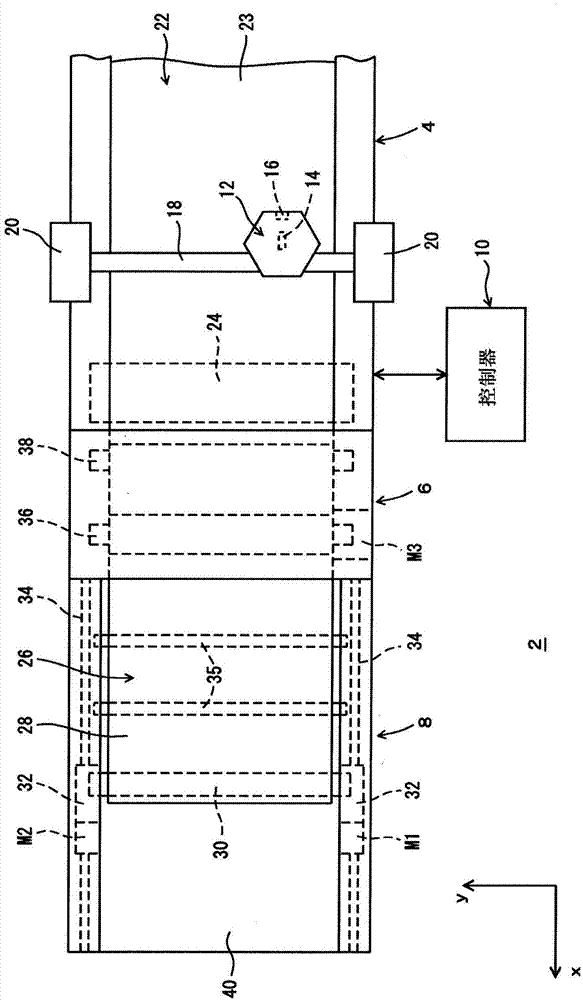

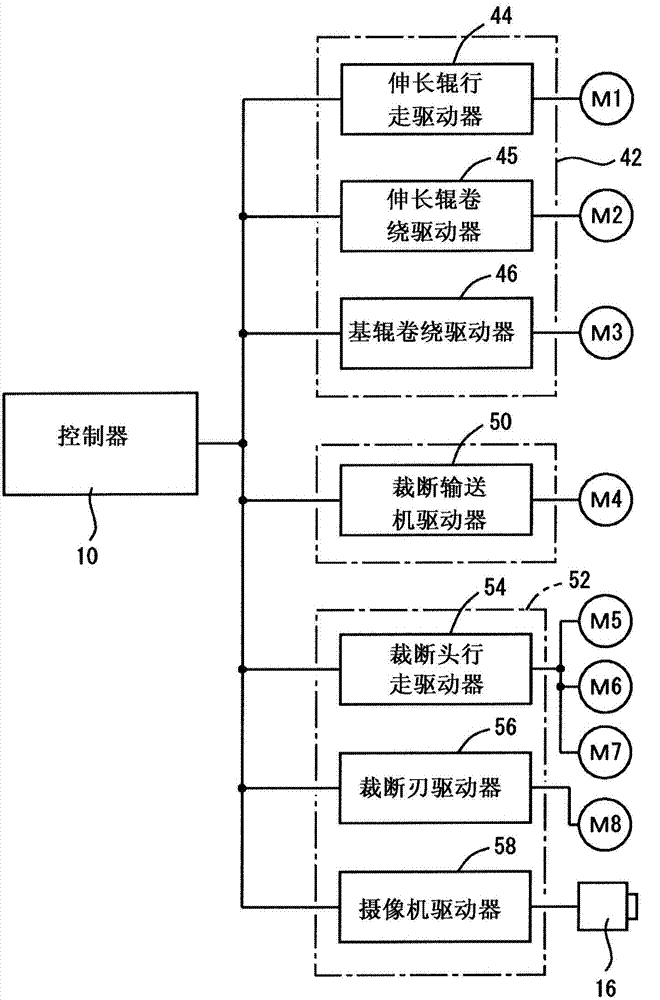

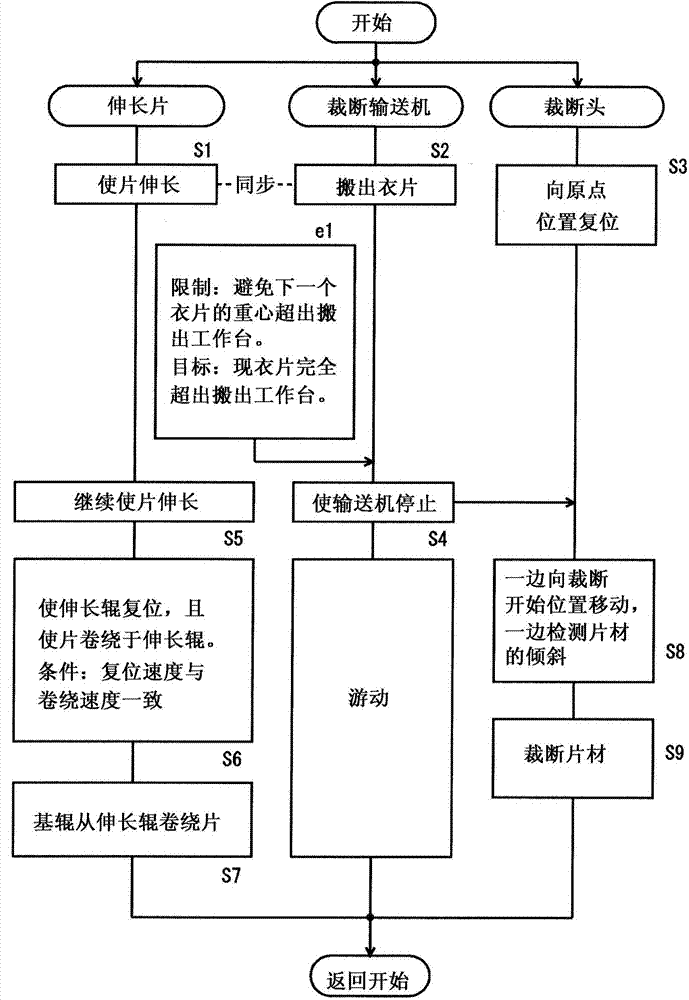

[0097] Figure 1 to Figure 5 The cutting and laminating apparatus 2 and the cutting and laminating method of the embodiment are shown in . like figure 1 As shown, in the cutting and stacking device 2, a cutting unit 4, a carry-out table 6, and a stacking unit 8 are arranged from upstream to downstream in the conveying direction of the sheet, and the cutting unit 4 and the stacking unit 8 are controlled by a controller 10. 12 is a cutting head, equipped with cutting blades 14, cameras 16 such as blades and round knives, along the direction of arm 18 figure 1 The y-direction moves through the triangular carriage 20, 20 to figure 1 to move in the x direction. The camera 16 detects the side edge of the sheet, and detects the direction from which the sheet is conveyed ( figure 1 the x-direction) of the tilt. The camera 16 may be provided in a member other than the cutting head 12 , and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com