Ladle filler sand feeding device

A technology of drainage sand and guide wheels, which is applied in the direction of metal processing equipment, casting melt containers, casting equipment, etc., can solve the problems of increased consumption, easy sintering of drainage sand, and large falling distance of drainage sand, so as to save usage and reduce Scattering, adding the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

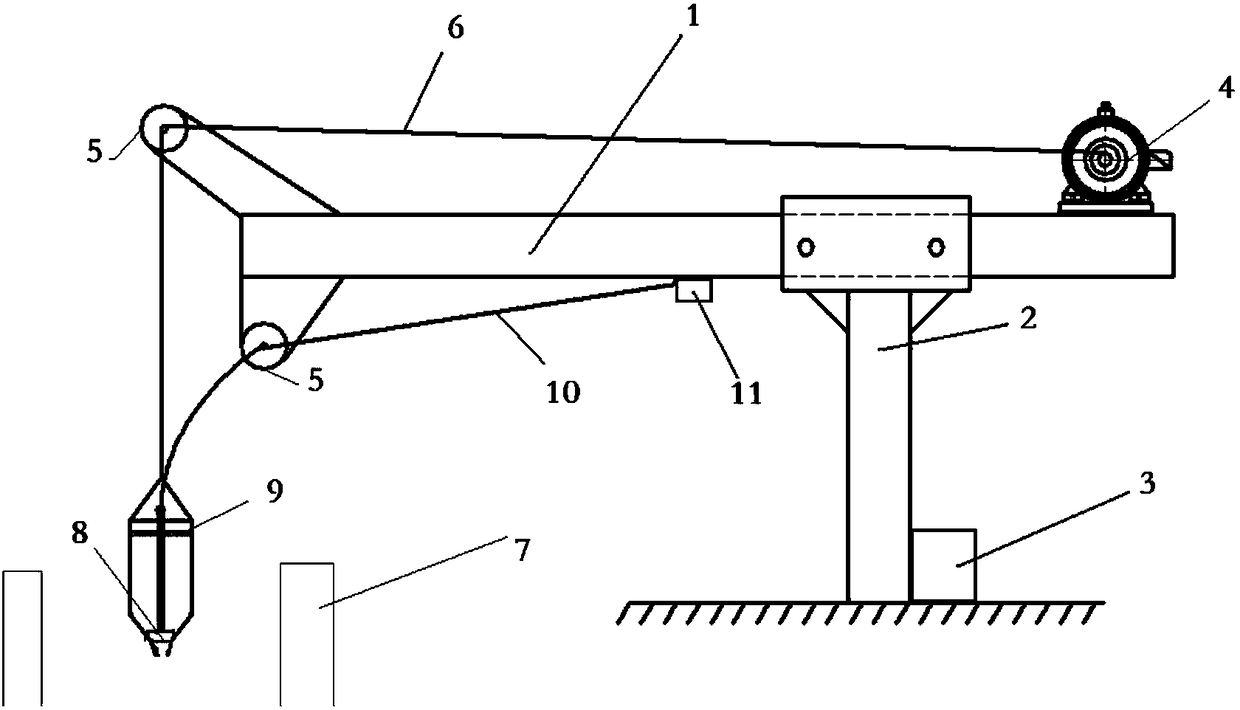

[0008] The present invention is specifically described below in conjunction with accompanying drawing, as figure 1 As shown, the present invention includes a swing arm 1 and a swing shaft 2, the swing arm 1 is fixed above the swing shaft 2, the swing shaft 2 is fixed on the ground, and a rotating motor 3 is arranged below the swing shaft 2 for driving the swing shaft 2 rotation; the rear portion of the swing arm 1 is provided with a motor reel 4, and the front end of the swing arm is provided with a guide wheel 5; the steel cable 6 on the motor reel 4 is connected with the barrel 9 through the guide wheel 5; a switch is arranged below the barrel 9 , the switch is controlled by the opening and closing cable 10; one end of the opening and closing cable 10 is connected to the switch, and the other end is fixed with the electric shaft 11 under the swing arm after the guide wheel 5 under the swing arm is bypassed.

[0009] The switch includes a valve cover 8 buckled above the disch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com