Patents

Literature

53results about How to "Material requirements are high" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

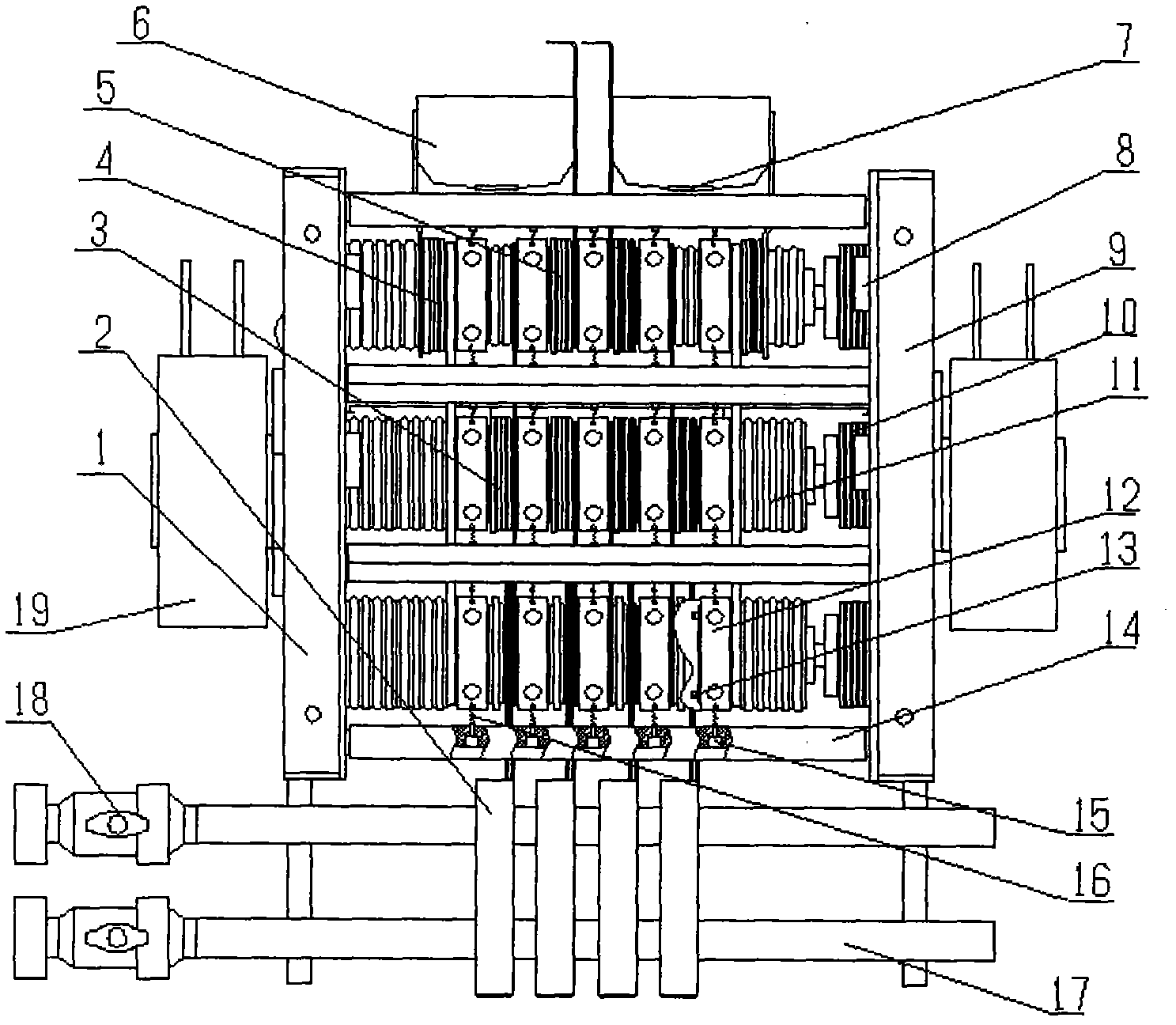

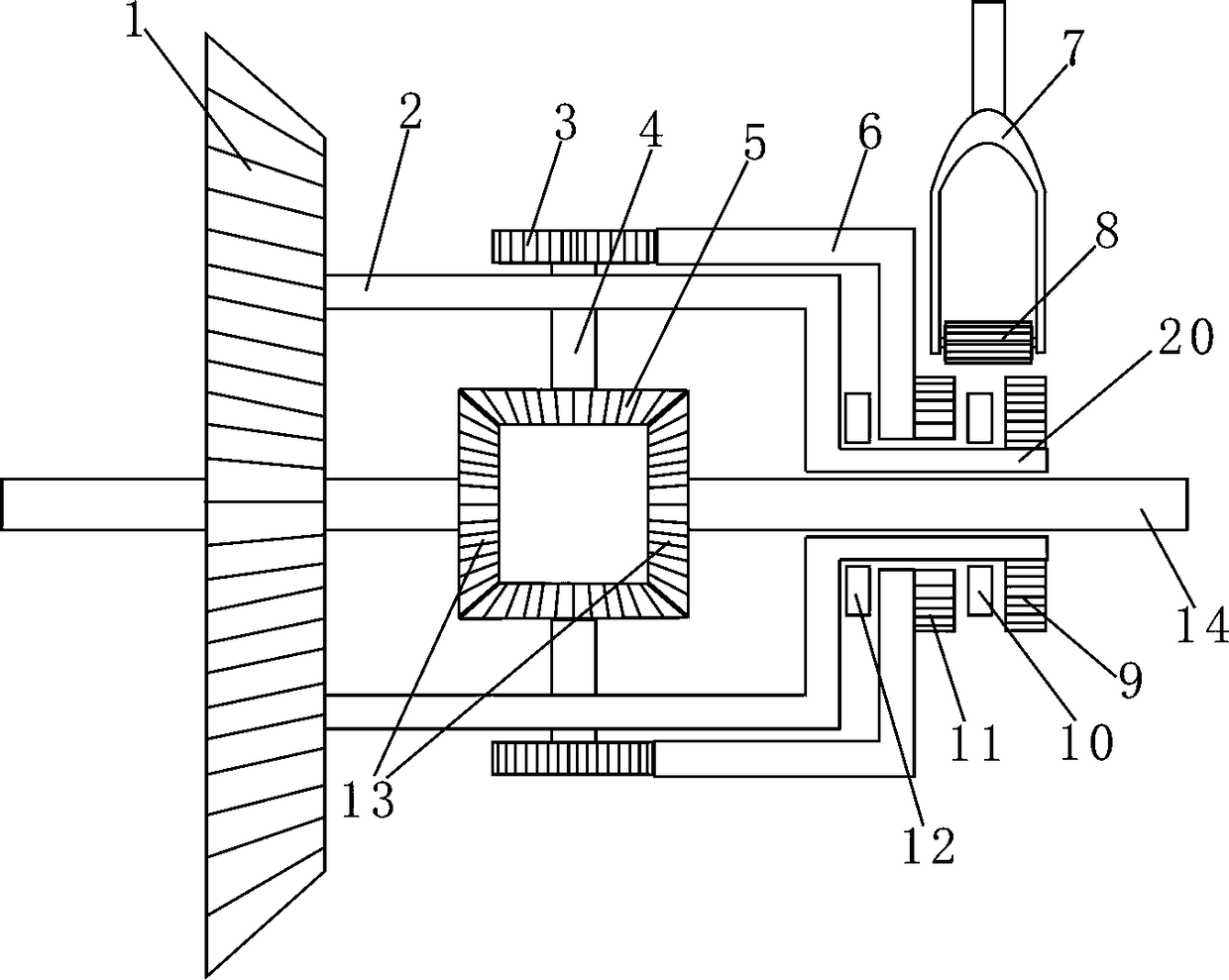

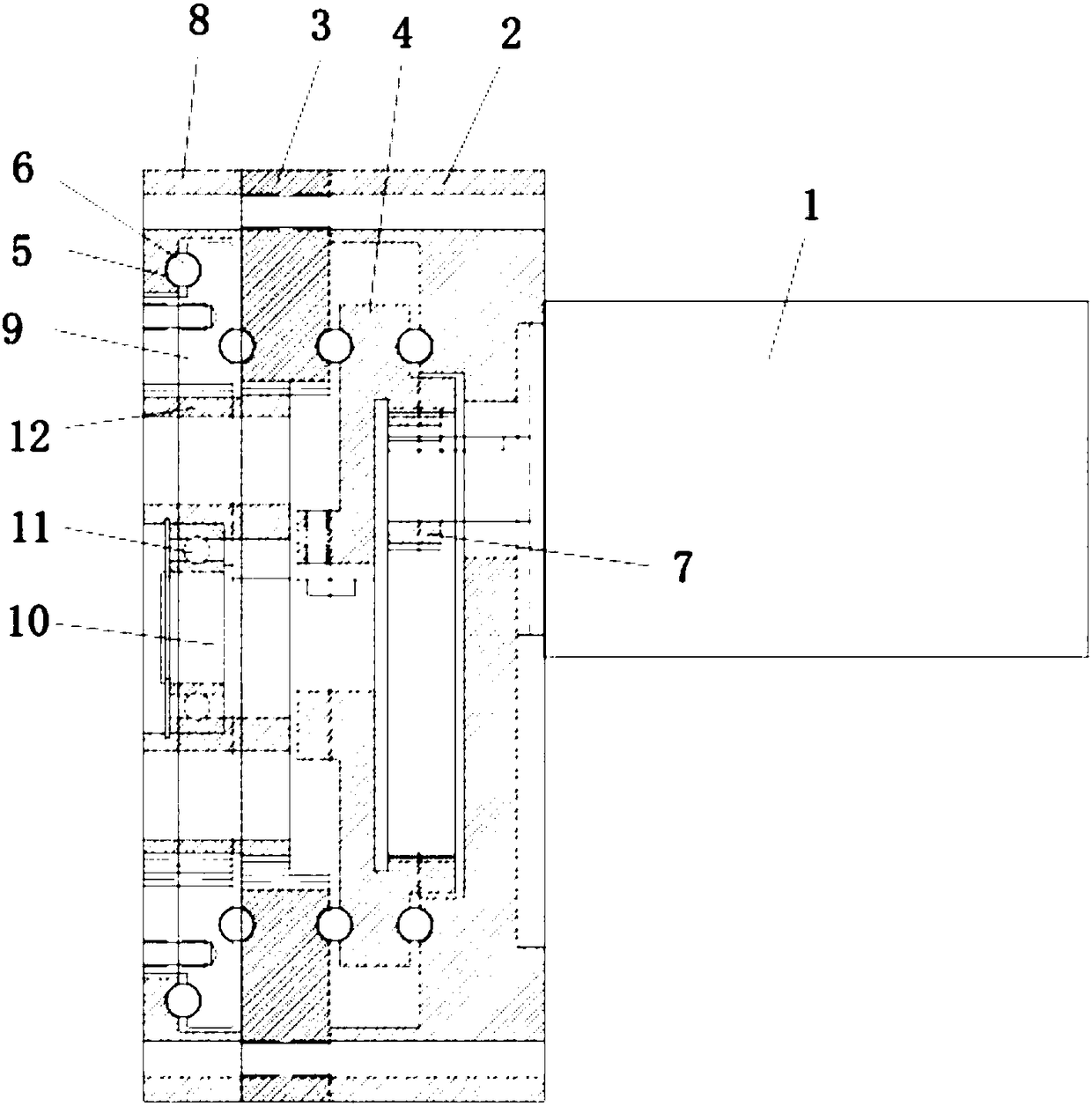

Integrated gate commutated thyristor (IGCT) three-level power module

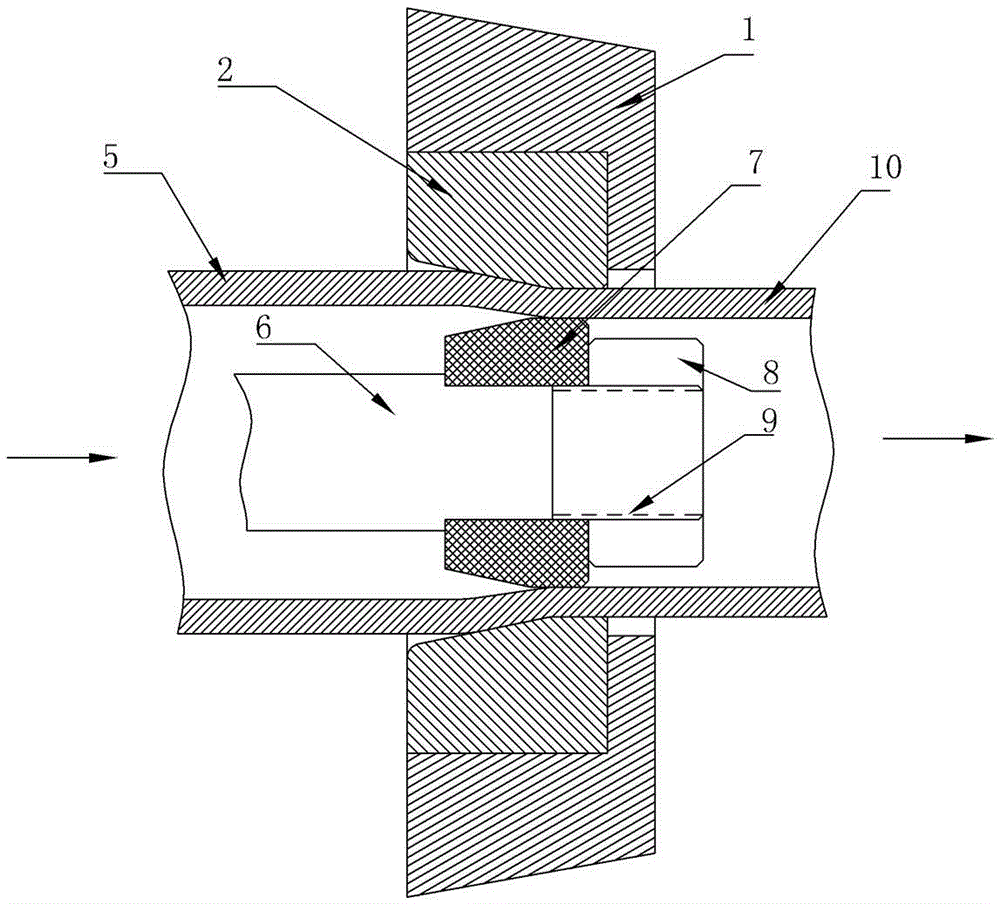

ActiveCN102064676AEasy maintenanceCompact structureCooling/ventilation/heating modificationsPower conversion systemsThree levelStray inductance

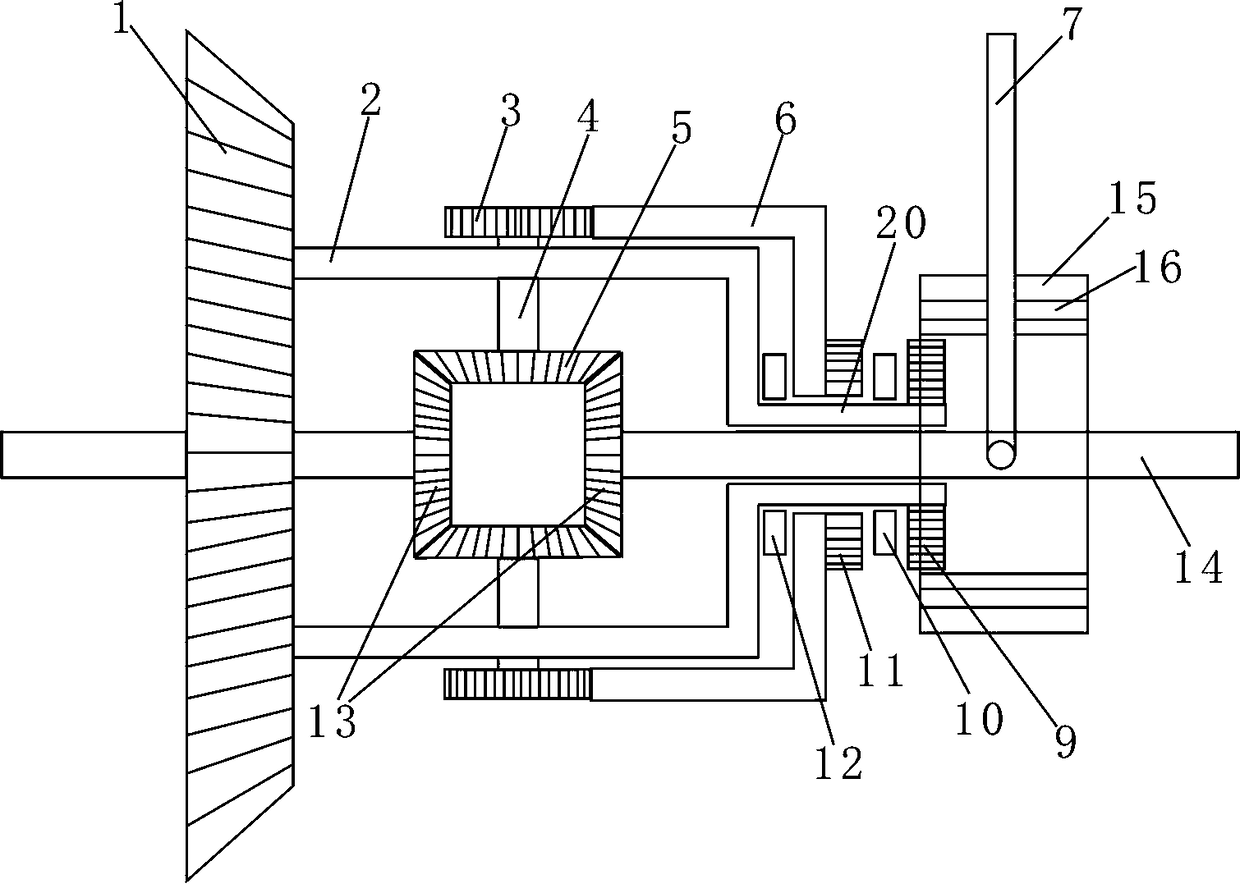

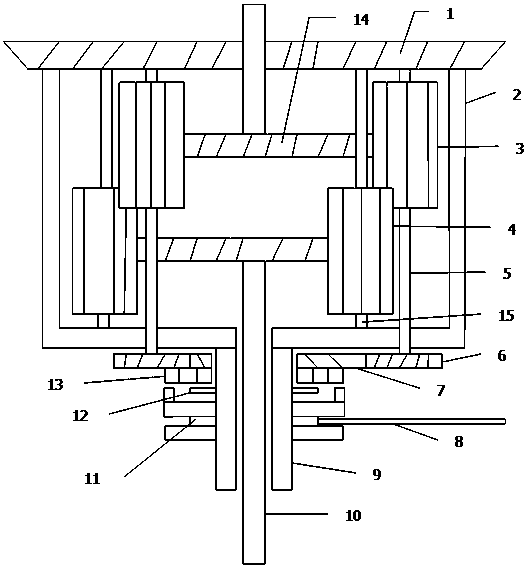

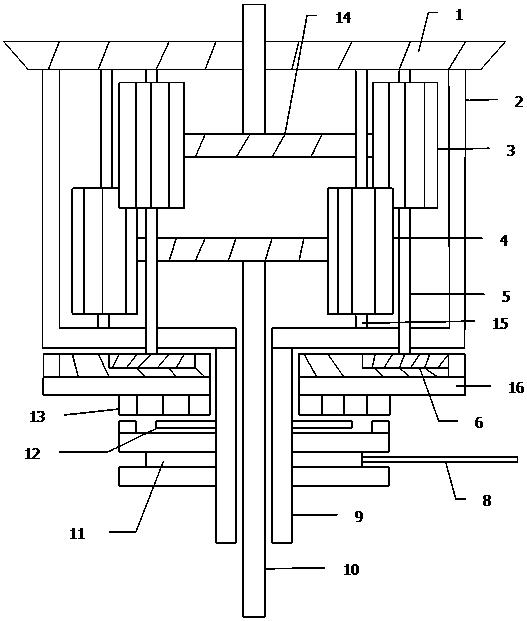

The invention relates to an integrated gate commutated thyristor (IGCT) three-level power module belonging to the technical field of high-power semiconductor switches. The IGCT three-level power module comprises an IGCT, an antiparallel flywheel diode, a left metal frame weld assembly, a right metal frame weld assembly, a pressing mechanism, a square water-cooling radiator, an insulating fixed pin, an insulating draw rod, an insulating hook pin, a P phase leading-in bus bar, a P phase leading-out bus bar, an M phase leading-out bus bar, an N phase leading-out bus bar, an N phase leading-in bus bar and the like. The invention adopts a structural style of three mutually parallel power strings, and each power string realizes the compression joint of electric / electronic components with the corresponding connecting bus bars, the square water-cooling radiator and insulators by the pressing mechanism. In the invention, absorption circuits are compactly arranged, thereby decreasing the mutual stray inductance; and a waterway interface and a power circuit interface are separated and are arranged respectively in the front and at the back.

Owner:AUTOMATION RES & DESIGN INST OF METALLURGICAL IND +1

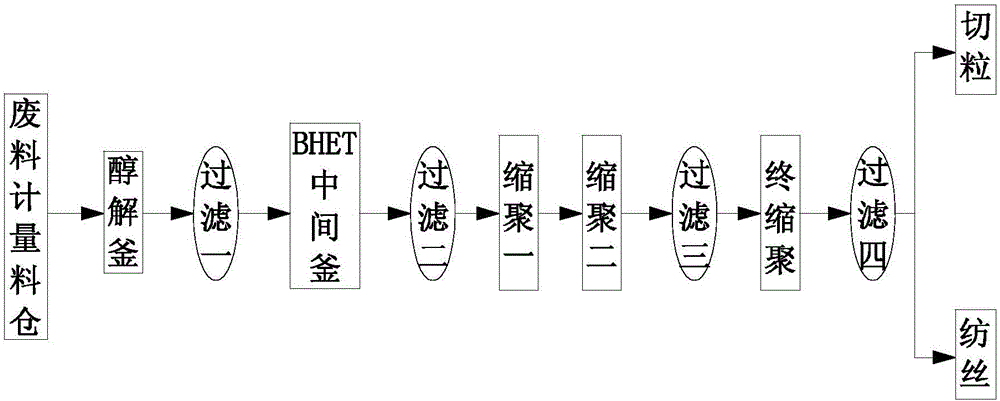

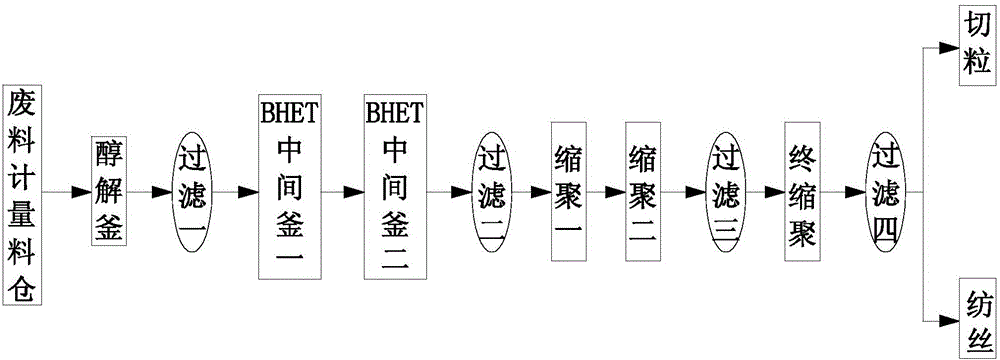

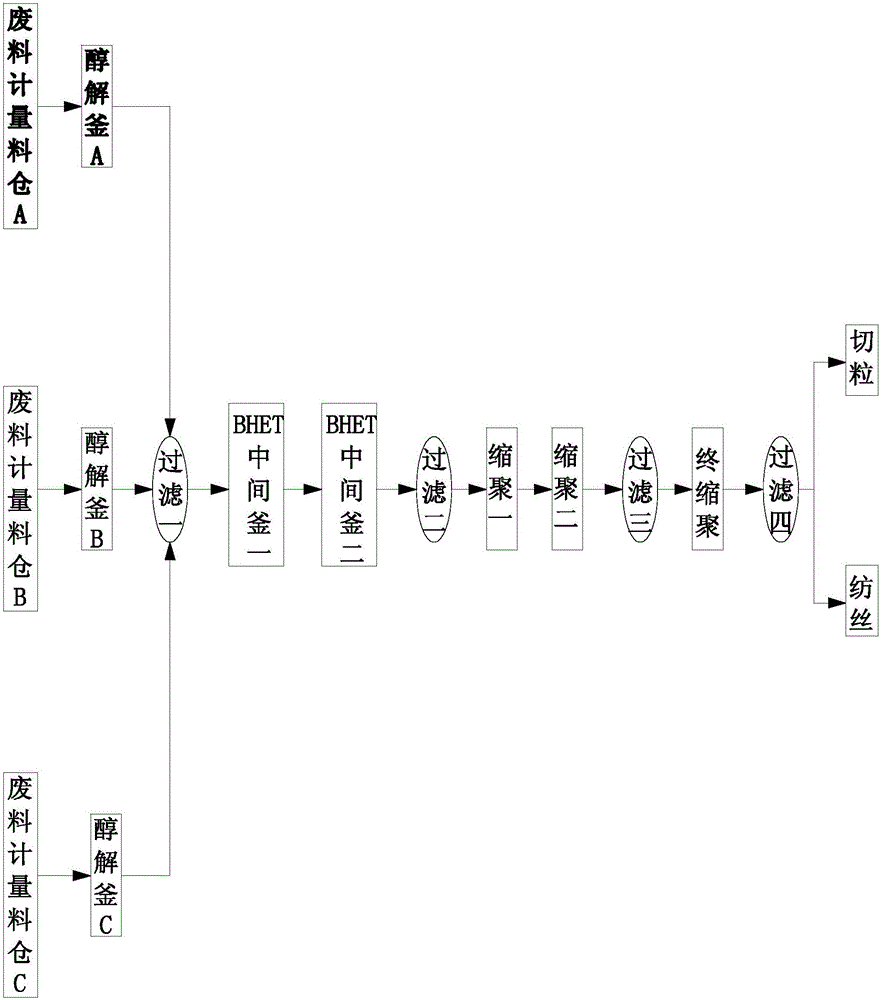

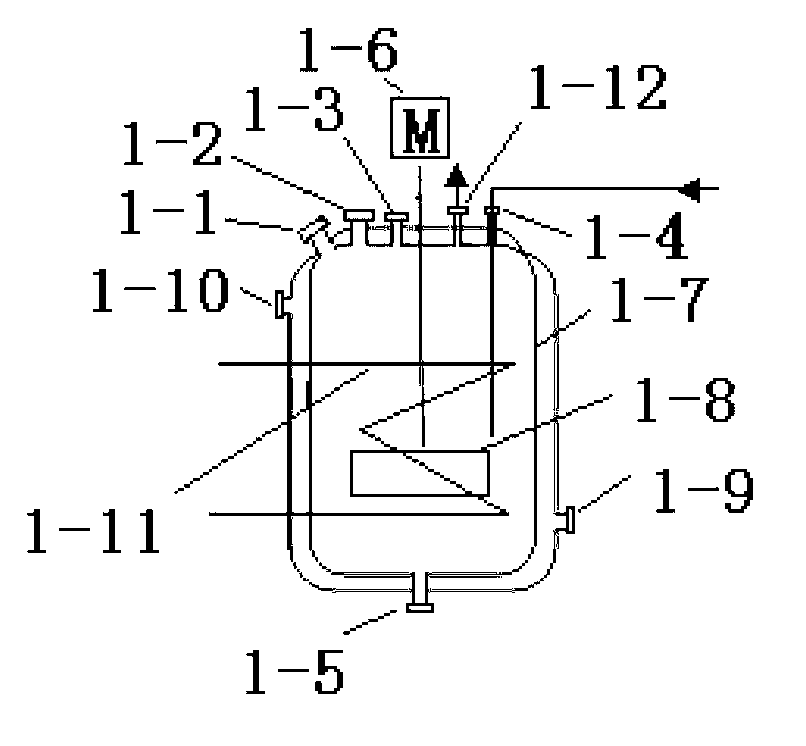

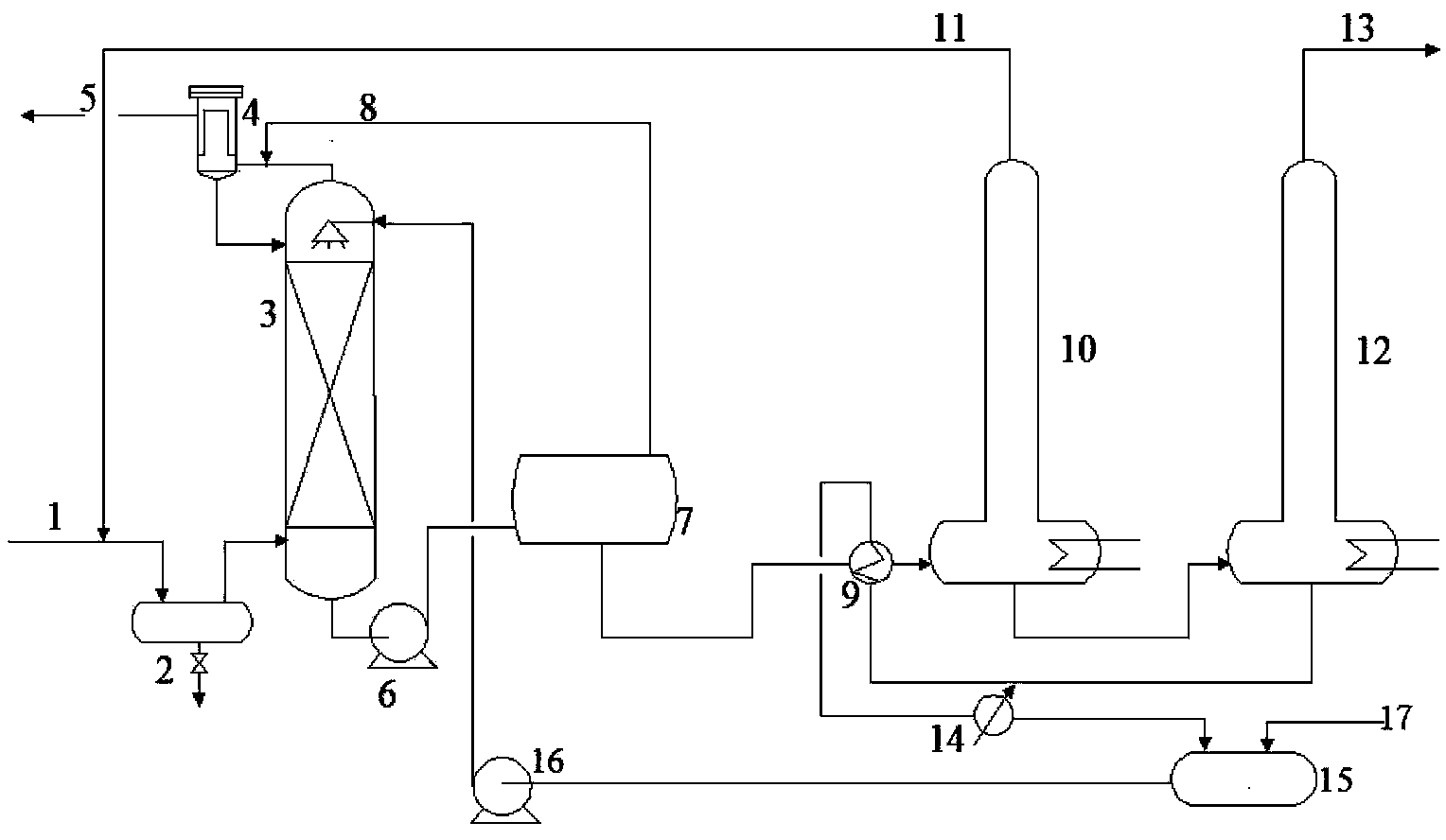

Recycling and regenerating process for waste textile containing polyester

The invention relates to a recycling and regenerating process for waste textile containing polyester and belongs to the technical field of polyester waste. The collected waste is smashed, rinsed, filtered, dried and metered so that finished products can be formed. The waste is dried after being smashed, rinsed and filtered, the waste is metered and conveyed into an alcoholysis kettle to complete alcoholysis and then is conveyed into a BHET middle kettle to react, then the waste is conveyed into a polycondensation kettle to complete polycondensation, and the finished products are formed through final polycondensation; and according to the alcoholysis process, the temperature of mother liquid ranges from 210 DEG C to 250 DEG C, and the reaction time ranges from 30 min to 5 h; the whole processing process is divided into four-stage filtering, the first-time filtering is completed after alcoholysis, the second-time filtering is completed after the reaction of the BHET middle kettle, the third-time filtering is completed after polycondensation, and the fourth-time filtering is completed after the final polycondensation, filter elements for four-stage filtering are 10-50 microns, and the filtering precision is sequentially improved from the first-time filtering to the fourth-time filtering. The recycling and regenerating process for the waste textile containing polyester is applied to waste silk and other polyester products and has the beneficial effects of being low in cost, short in process, high in quality, free of pollution and the like.

Owner:ZHEJIANG LUYU ENVIRONMENTAL PROTECTION

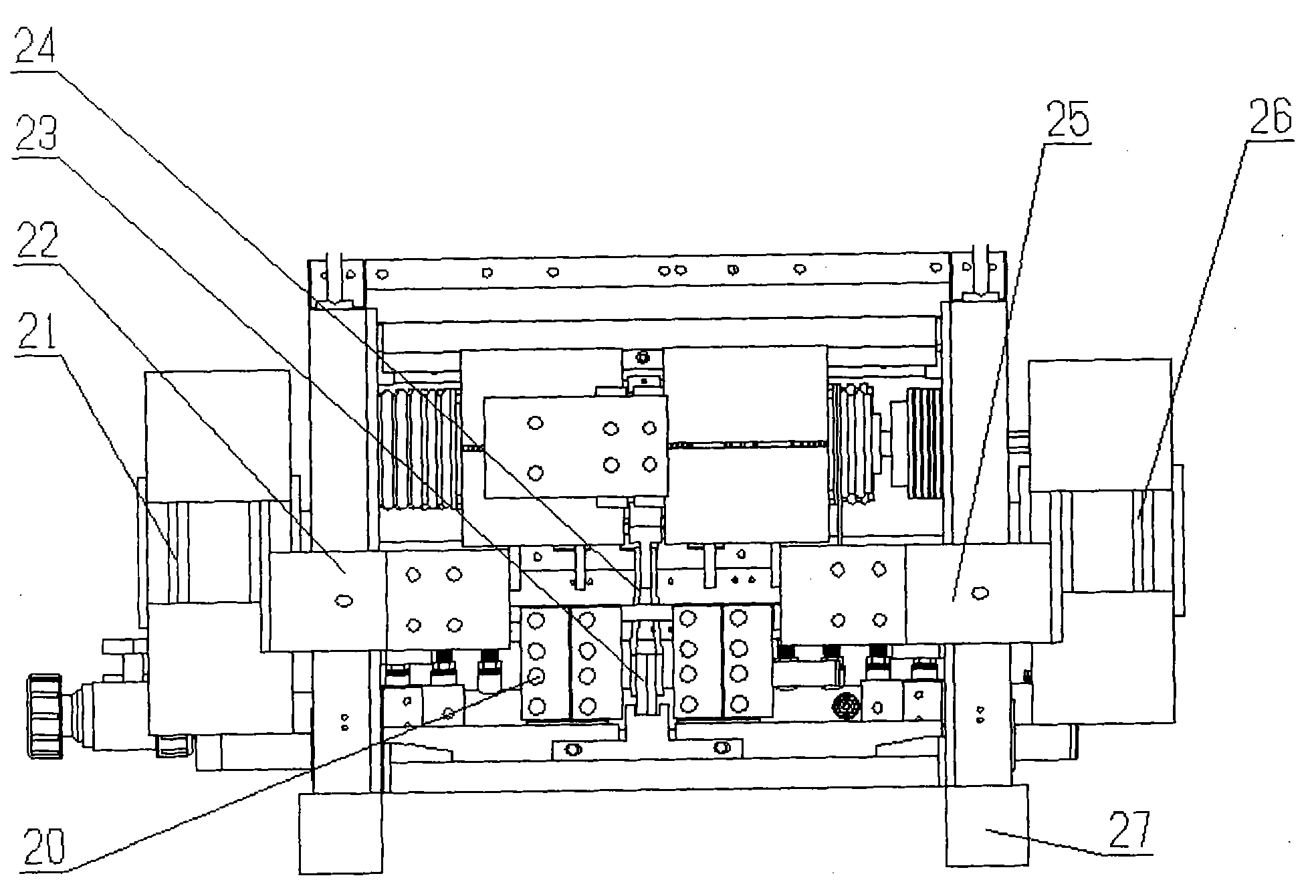

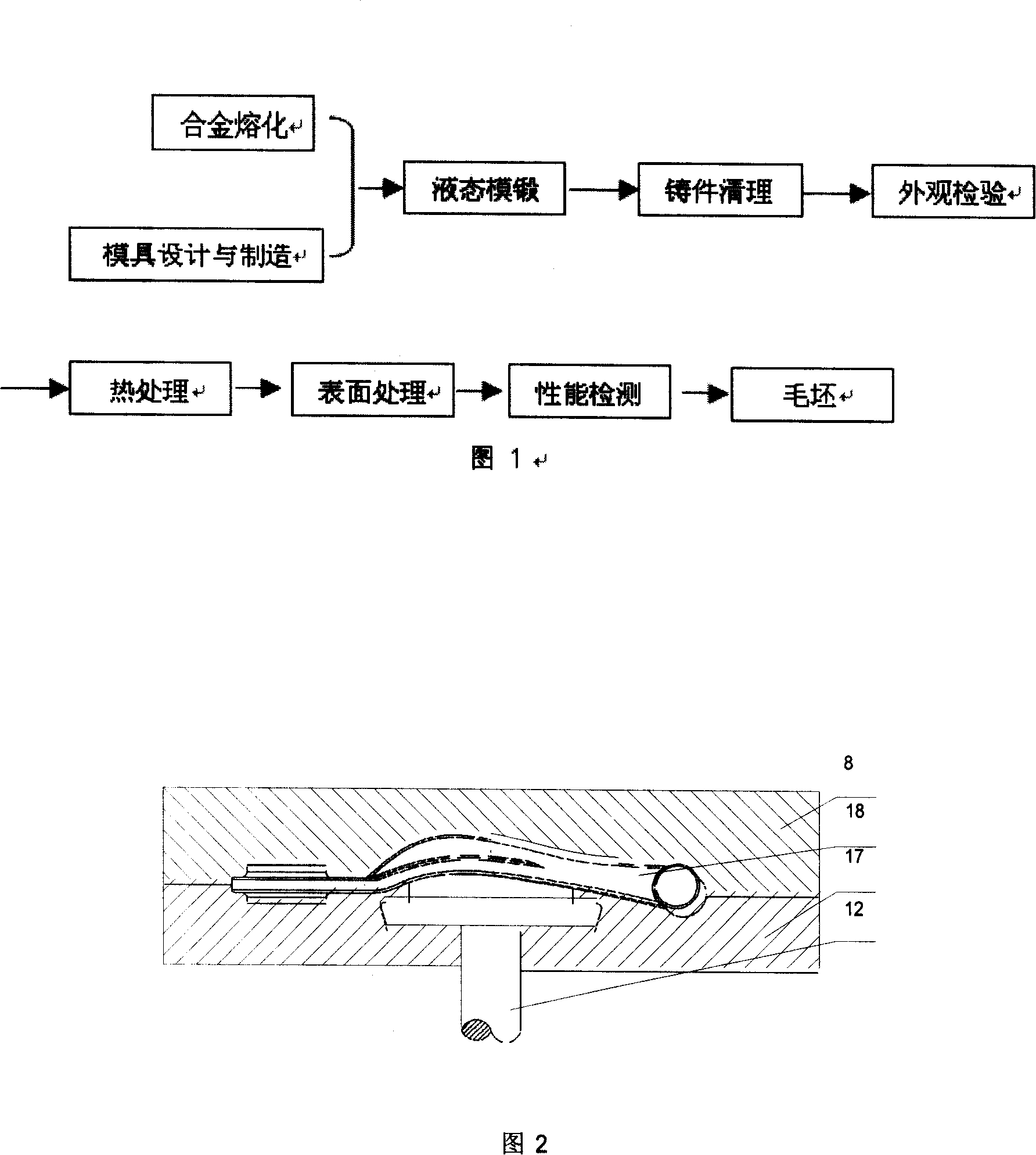

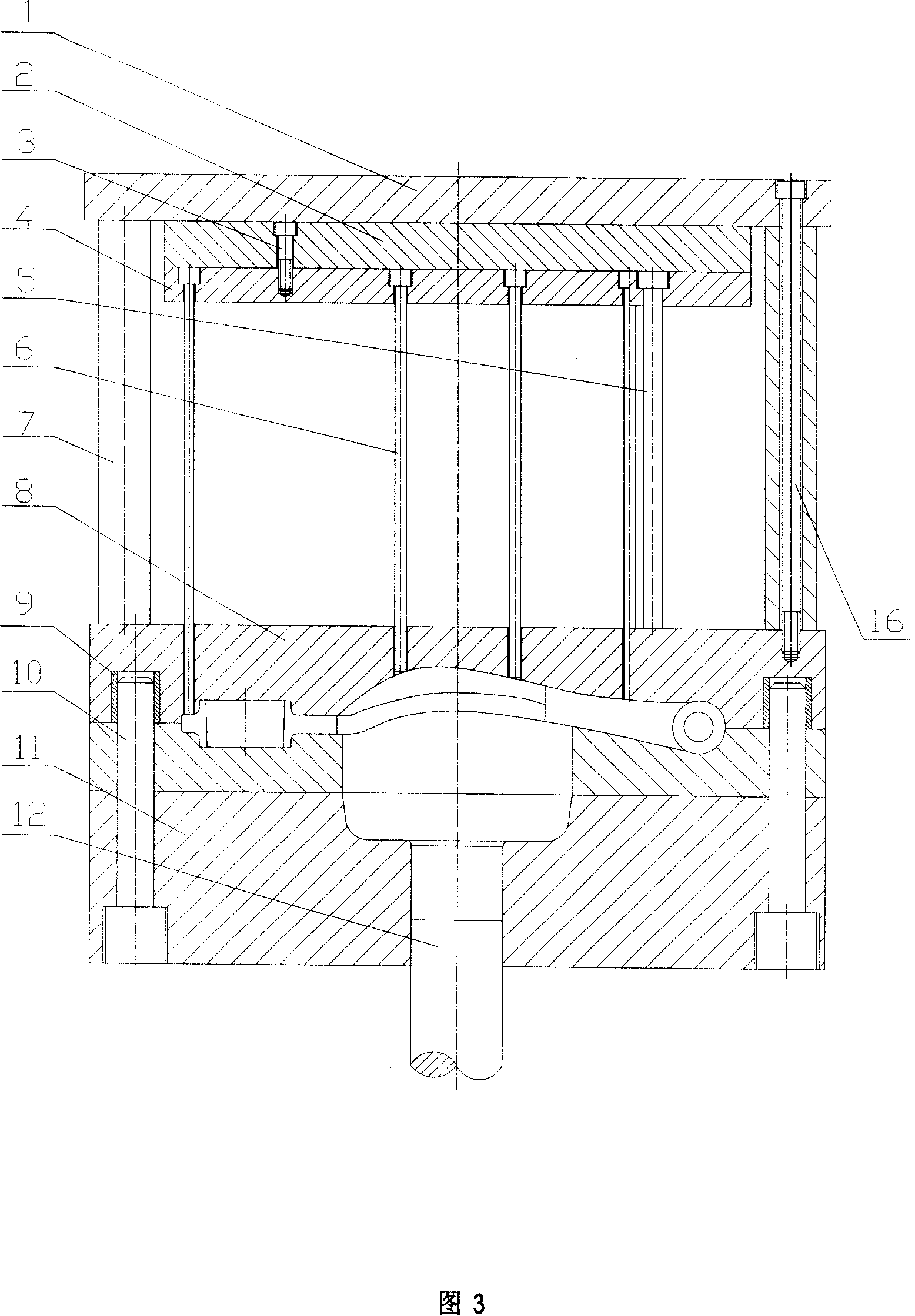

Aluminum alloy precast-forging forming technique and mold thereof

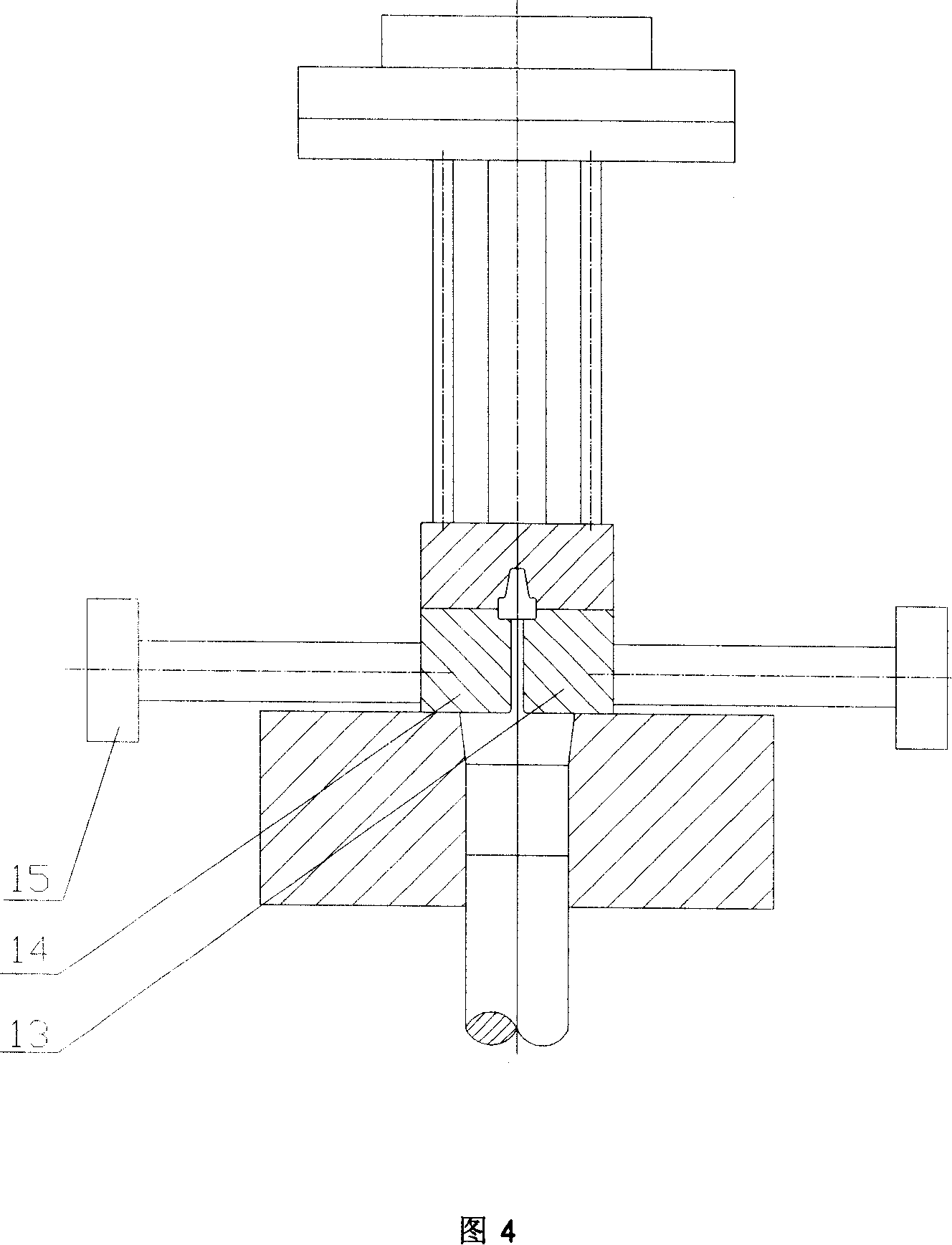

The invention relates to a forging technology and a device, in particular to aluminum alloy liquid forging molding technology and a module. In light of the technical problems that the prior art adopts complex module and process not suitable for aluminum alloy liquid forging, etc., the invention provides the forging module with simple structure and easy operation as well as the aluminum alloy liquid forging molding technology with reasonable process. The main technical proposal of the invention is as follows: a lower left module and a lower right module are arranged and fixed on a lower template in parallel, and a cylinder bottom punch gets through the lower template and is arranged between the lower left module and the lower right module; liquid aluminum alloy is injected into a cavity through a pouring port between the lower left module and the lower right module; an upper module is arranged on the lower left module and the lower right module and a pillar is also arranged and fixed; when in forging, the cylinder bottom punch conducts upward squeezing movement on liquid aluminum alloy; after meeting forging requirement, pressure can be maintained for 30 to 50 minutes.

Owner:宁波拓普隔音系统有限公司

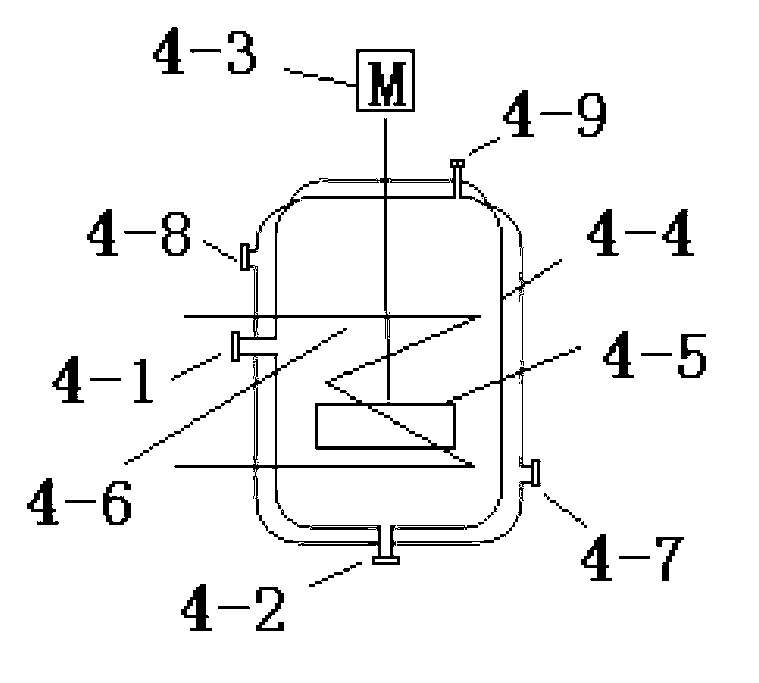

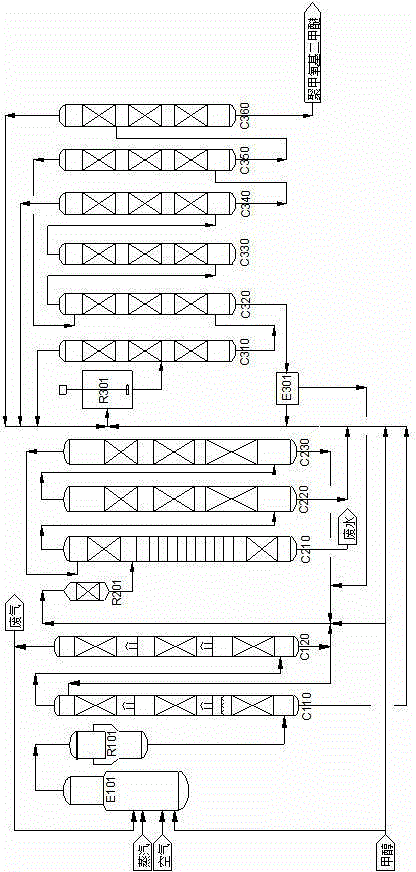

Preparation method of aromatic polycarbonate

The invention relates to aromatic polycarbonate and a preparation method of the aromatic polycarbonate. The method comprises the steps of diaryl carbonate and aromatic dihydroxy compound raw material deoxygenation treatment, raw material and catalyst melt mixing, prepolymerization, prepolymer and carrying agent gas-liquid mixing, mixture heat exchange, polymerization reaction in a multi-section flow guide falling film type polycondensation reactors and the like. The aromatic polycarbonate produced by adopting the method provided by the invention has the advantages that the molecular weight isstable, the distribution is narrow, and the product chromaticity is good. The method solves the environment pollution problem, the serious equipment corrosion problem and the problem of performance influence caused by the separation and purification difficulty of polycarbonate products in the existing interface polycondensation method. Therefore, the method provided by the invention is very suitable for the industrial large-scale production of high-quality polycarbonate.

Owner:SHAANXI YANCHANG PETROLEUM GRP +2

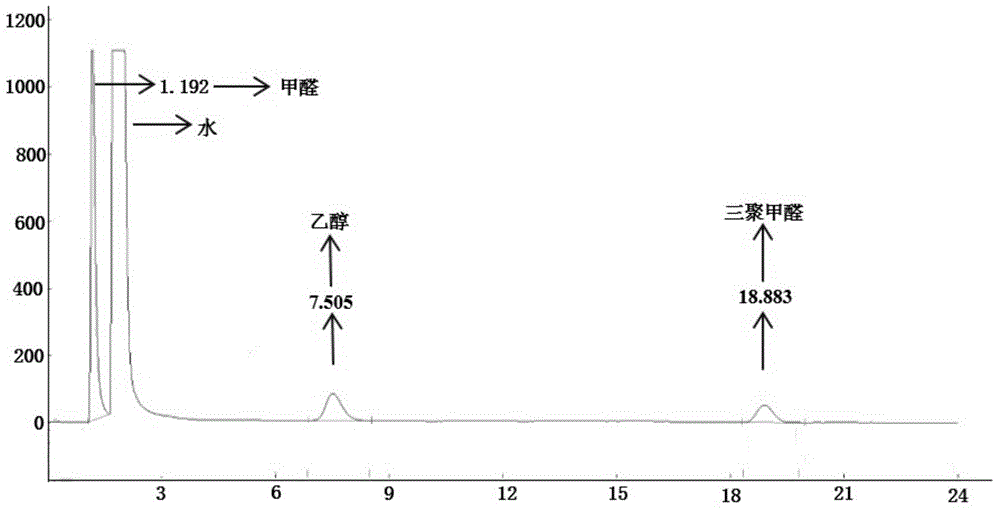

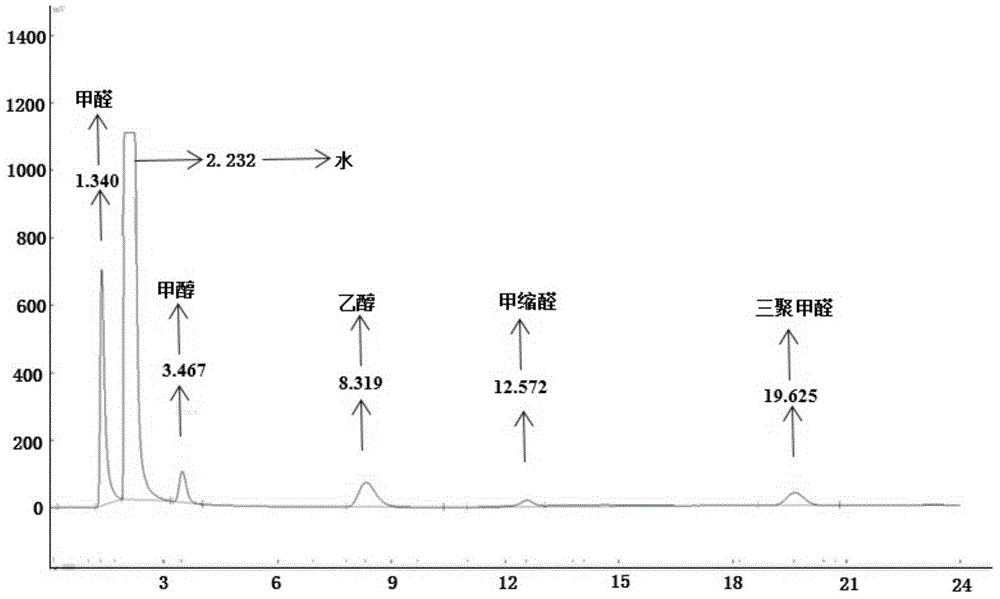

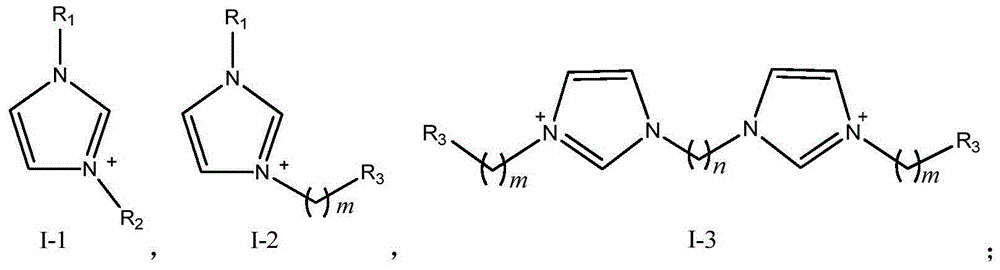

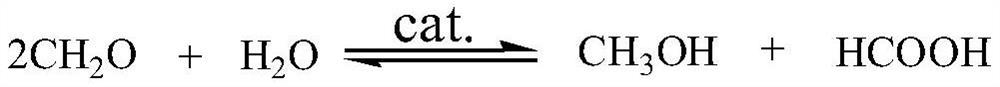

Method for synthesizing trioxymethylene

InactiveCN105218513AAvoid consumptionHigh latent heat of vaporizationOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsSolventDimethoxymethane

The invention provides a method for synthesizing trioxymethylene. The method comprises the step of carrying out a reaction at 30-150 DEG C for 0.1-5 hours to synthesize trioxymethylene by using an ionic liquid as a solvent and a catalyst and solid paraformaldehyde as a raw material, wherein the use amount of the solid paraformaldehyde is not more than 80% of total mass of the ionic liquid and the solid paraformaldehyde. By using the solid paraformaldehyde as the raw material and the ionic liquid as the solvent and the catalyst, the method provided by the invention is free of byproducts such as methyl formate, methanol, methylal and the like, and can remarkably improve the balanced yield of trioxymethylene and reduce the energy consumption, and the ionic liquid can be repeatedly used, so that the production cost is lowered.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

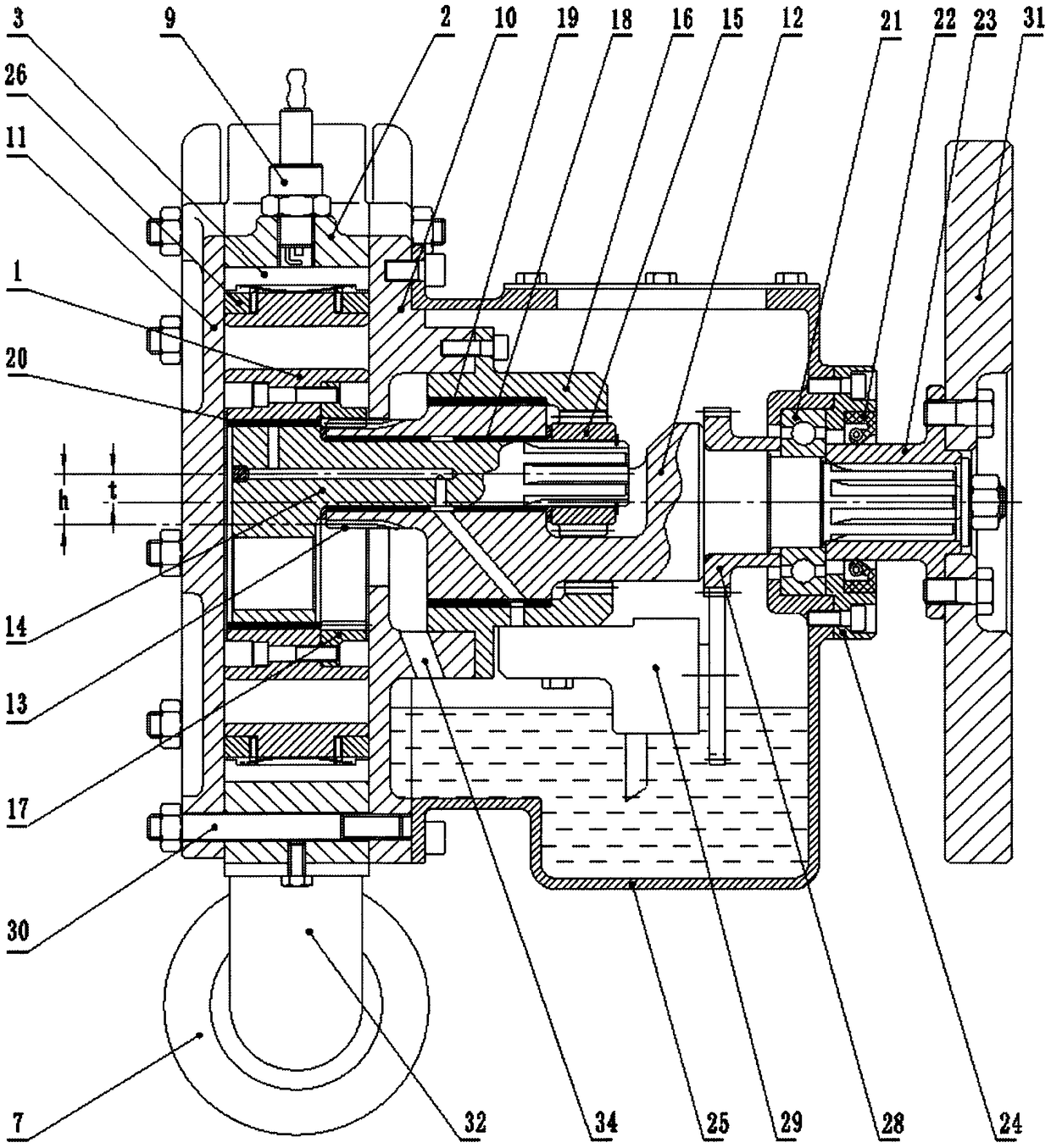

Differential locking mechanism

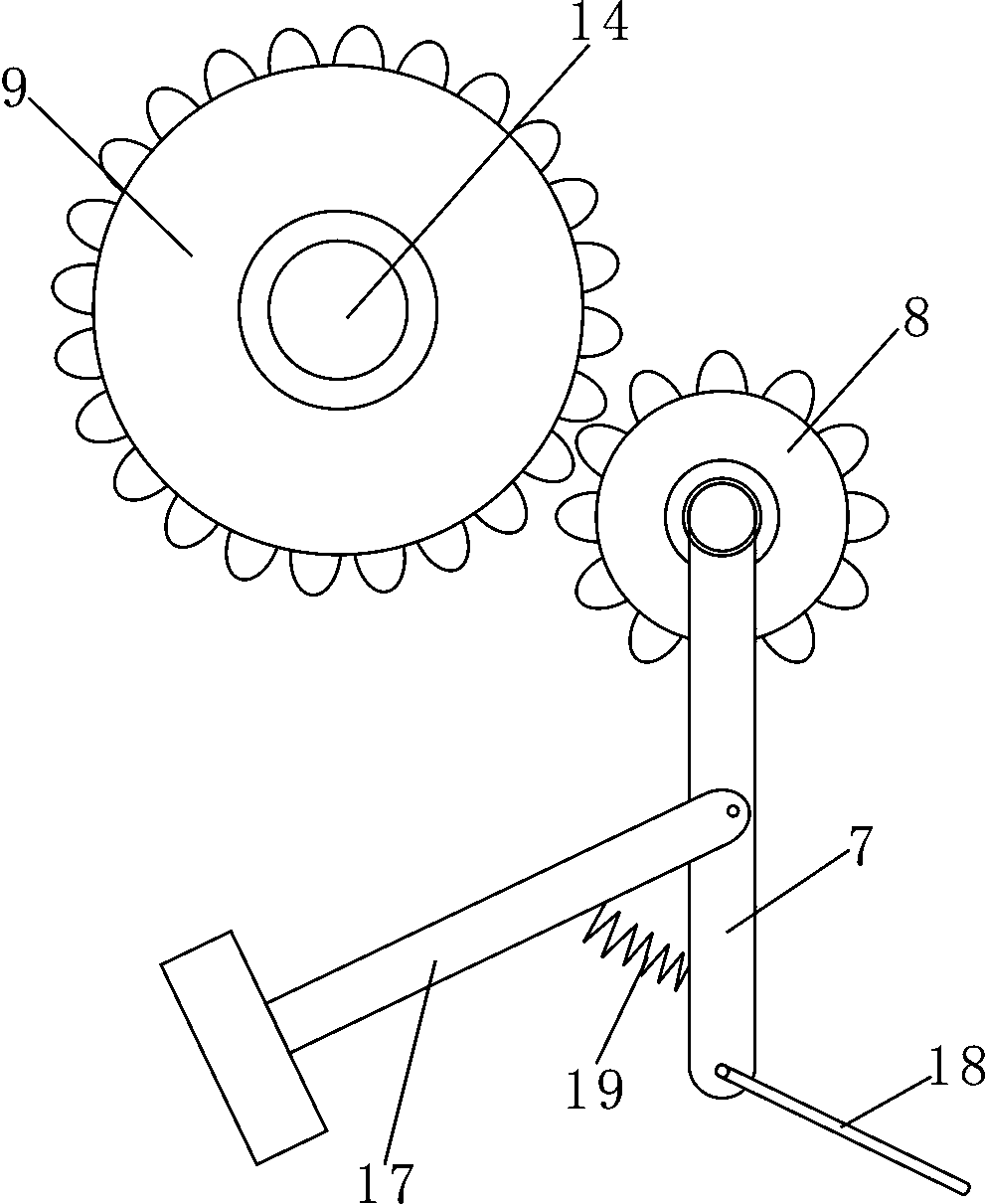

The invention provides a differential locking mechanism. The differential locking mechanism comprises a differential mechanism and a locking mechanism. A gear A is fixedly arranged at the end, towardsthe outside of a differential mechanism shell, of a rotary shaft, a sleeve is integrally arranged at the right end of the differential mechanism shell, a semi-shaft located on the right side of the differential mechanism shell is sleeved with the sleeve, and the sleeve and the semi-shaft are movably connected. A gear B is fixedly arranged on the sleeve, the right end of the differential mechanismshell is sleeved with a barrel-shaped gear, the barrel-shaped gear and the differential mechanism shell are rotationally connected, the barrel-shaped gear and the sleeve are rotationally connected, insection is fixedly arranged at the position of an opening of the barrel-shaped gear, the barrel-shaped gear and the gear A are engaged, a gear C is fixedly arranged at the tail end of the barrel-shaped gear, the sleeve is sleeved with the gear C, and the gear C and the sleeve are rotationally connected.

Owner:郭放

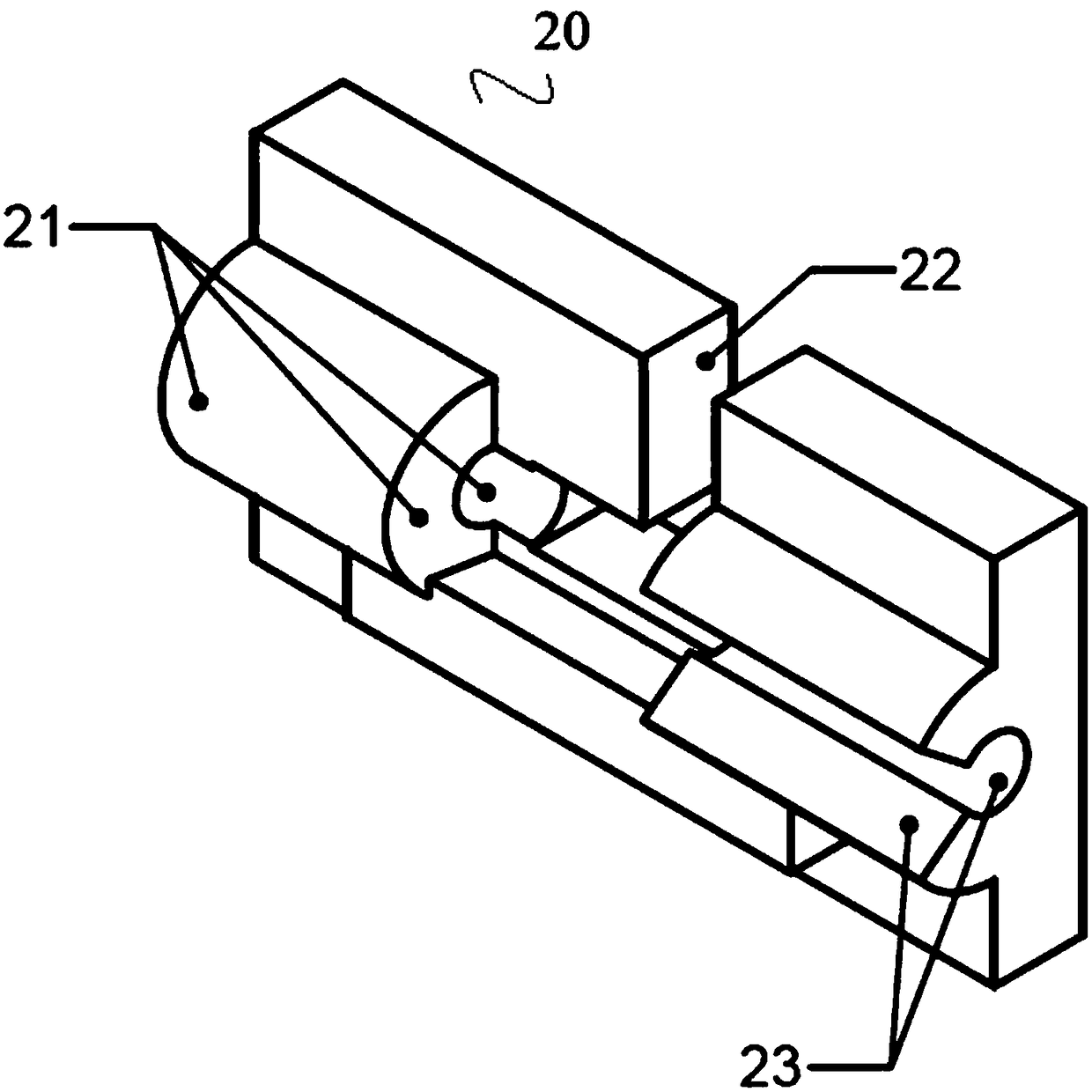

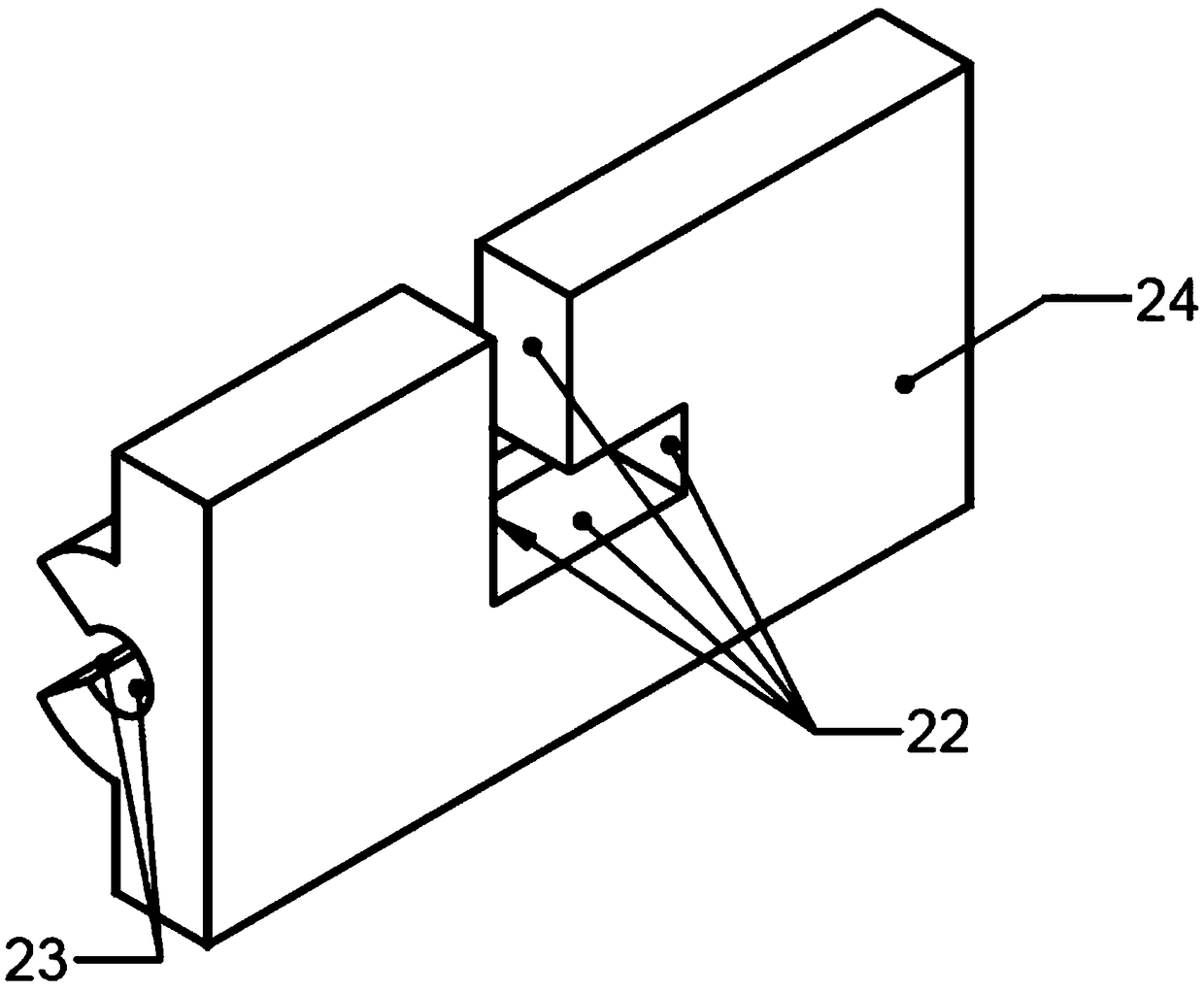

Rolling forming die for disposable hygiene product

ActiveCN103231417AImprove single service lifeExtended service lifeMetal working apparatusRubber ringEngineering

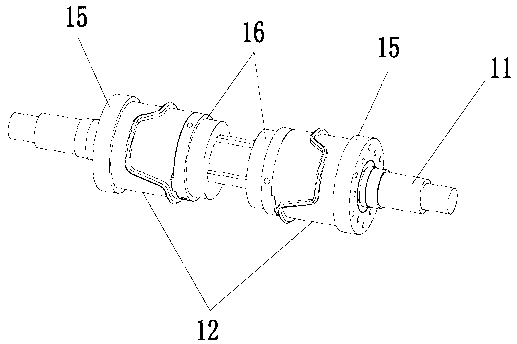

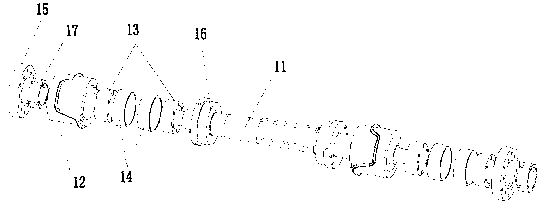

A rolling forming die for a disposable hygiene product comprises a machine frame, a first roller and a second roller, wherein the first roller and the second roller are parallelly and fixedly assembled on the machine frame, the first roller comprises a middle shaft, movable cutter dies, adjusting sleeves and protective sleeves, the movable cutter dies, the adjusting sleeves and the protective sleeves are fixed on the middle shaft, a pair of adjusting sleeves is fixed in each movable cutter die, the adjusting sleeves are in a circular truncated cone shape, a layer of rubber ring is poured on the lateral side of each adjusting sleeve, the protective sleeve is fixed at one end of the movable cutter die, and the protective sleeve is fixed on the middle shaft through an expanding sleeve. By means of the technical scheme of the rolling forming die, service life of the die for single use is prolonged, and the adjusting sleeves provided with the rubber rings are arranged in the movable cutter dies and have the buffering effect, so that abrasion on a bottom roller and the cutter dies is reduced, and simultaneously the die cost and the production cost are reduced.

Owner:泉州市振鑫机械制造有限公司

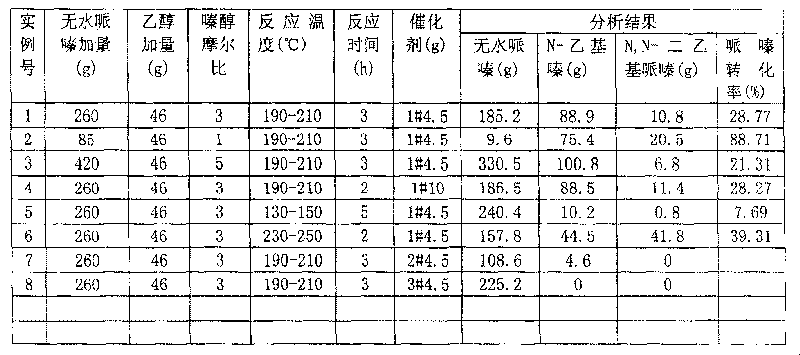

Process for synthesizing N-ethyl piperazidine

ActiveCN1962649AHigh standardThe three wastes are difficult to deal withOrganic chemistryMetal/metal-oxides/metal-hydroxide catalystsBromineChemistry

The invention discloses a synthesizing method of N-ethyl piperazine, which comprises the following steps: adopting Cu-Co-M0 / Al2O3 as catalyst with 1-70% Cu, 1-90% Co,1-30% Mo, 0.1-10% Ni, 0.05-10% Mn, 0.01-5.0% Mg, 0.01-5.0% Cr and Al2O3; setting the pressure of liquid phase at 0.1-10.0Mpa under 80-350 Deg C in the interval course with surplus piperazidine; making the molar rate of piperazidine and alcohol at 0.5-10.0 with 0.1-5.0% catalytic cracking quantity.

Owner:ZHEJIANG XINHUA CHEM +1

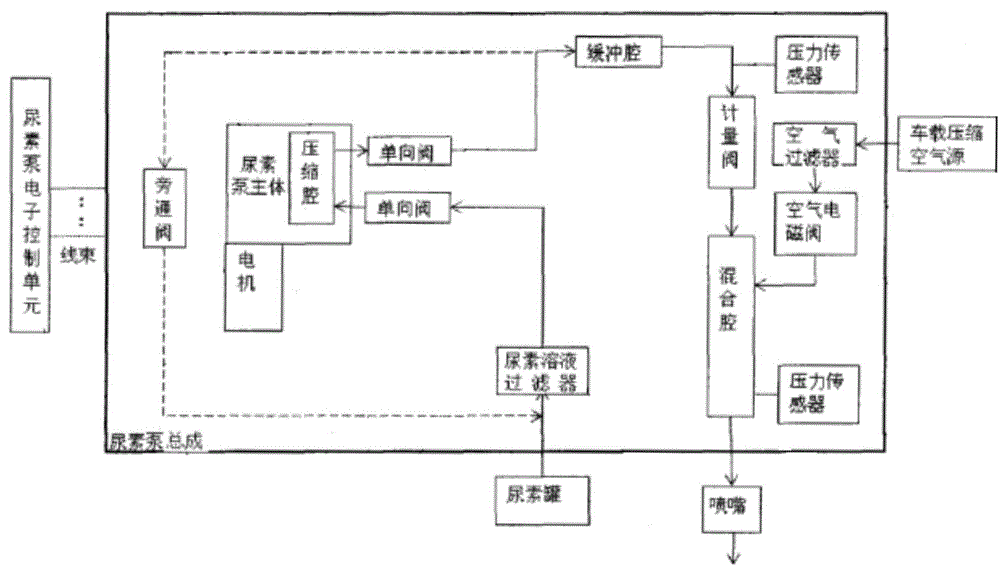

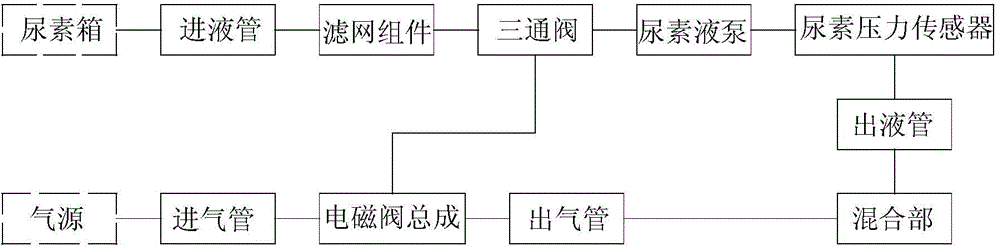

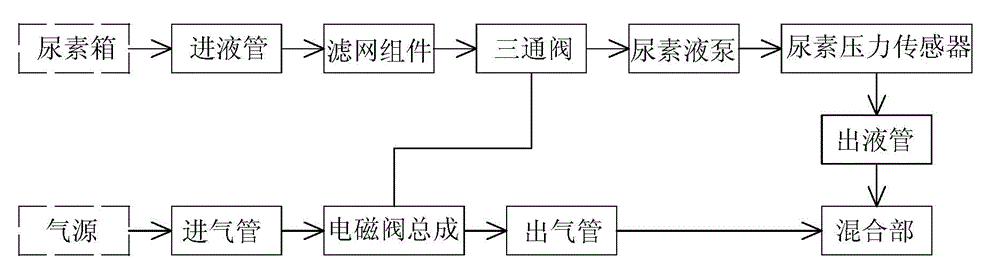

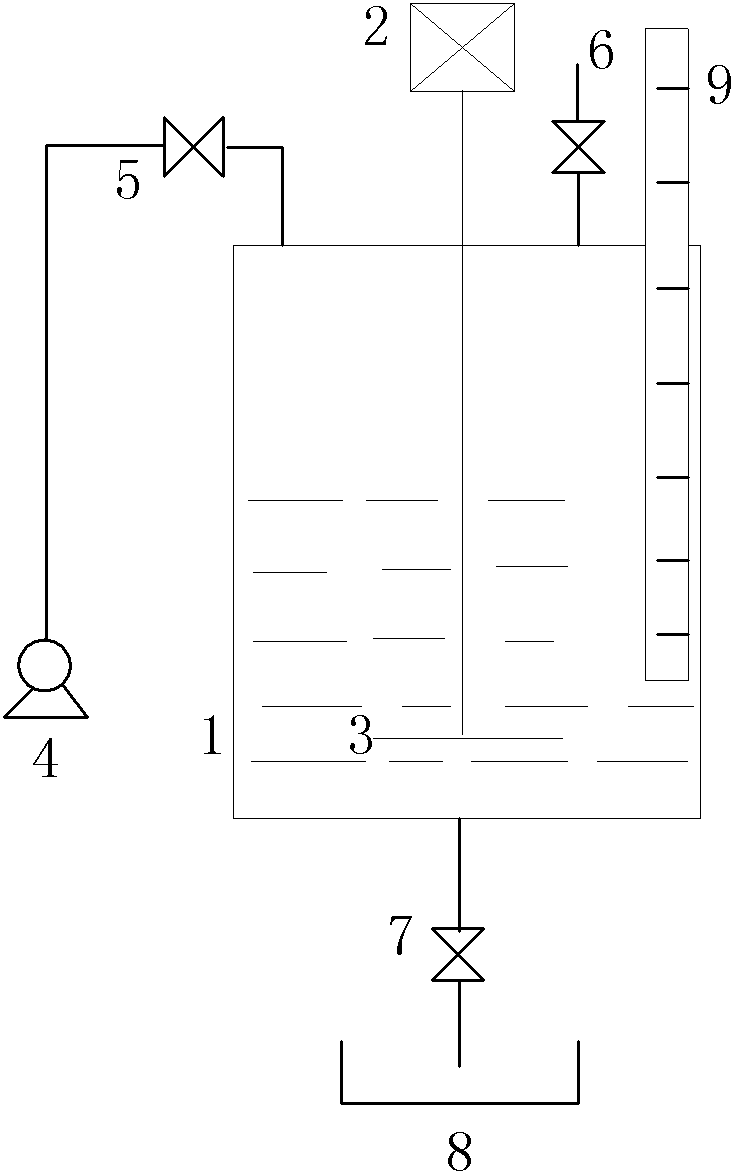

Urea pump and urea system containing same

ActiveCN104819039AAchieve backflush (Realize functionExhaust apparatusSilencing apparatusChemistryUrea

The invention discloses a urea pump and a urea system containing same. The urea pump comprises a urea branch and a gas branch; the urea branch comprises a liquid feeding part, a liquid outlet part, a urea liquid pump and a first switch device, wherein the liquid inlet part is used for providing a urea solution inlet, a liquid outlet part is used for providing a urea solution outlet, the urea liquid pump is used for providing power for feeding urea solution to the liquid outlet part from the liquid inlet part, and the first switch device is used for realizing the selective communication between the liquid inlet part and the liquid outlet part; the gas branch comprises an air inlet part, an air outlet part and a second switch device, wherein the air inlet part is used for providing a gas inlet, the air outlet part is used for providing a gas outlet, and the second switch device is used for realizing the selective communication between the air inlet part and the air outlet part; the first switch device is connected with the second switch device so that the urea branch is selectively communicated with the gas branch. According to the urea pump provided by the invention, the function of a traditional urea pump can be realized, and the function of back flushing urea can be realized.

Owner:DONGGUAN ZHENGYANG ELECTRONICS MECHANICAL CO LTD

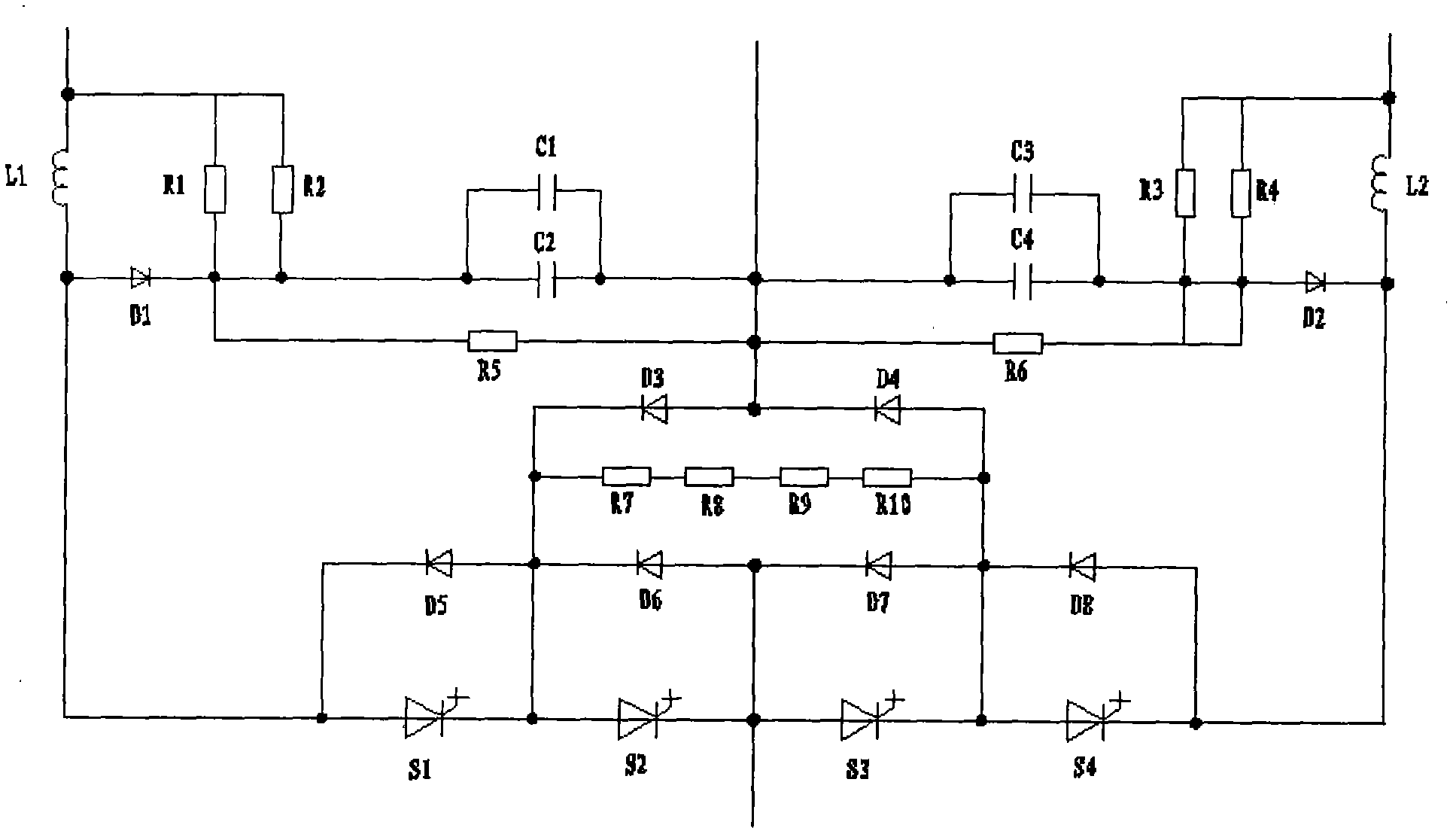

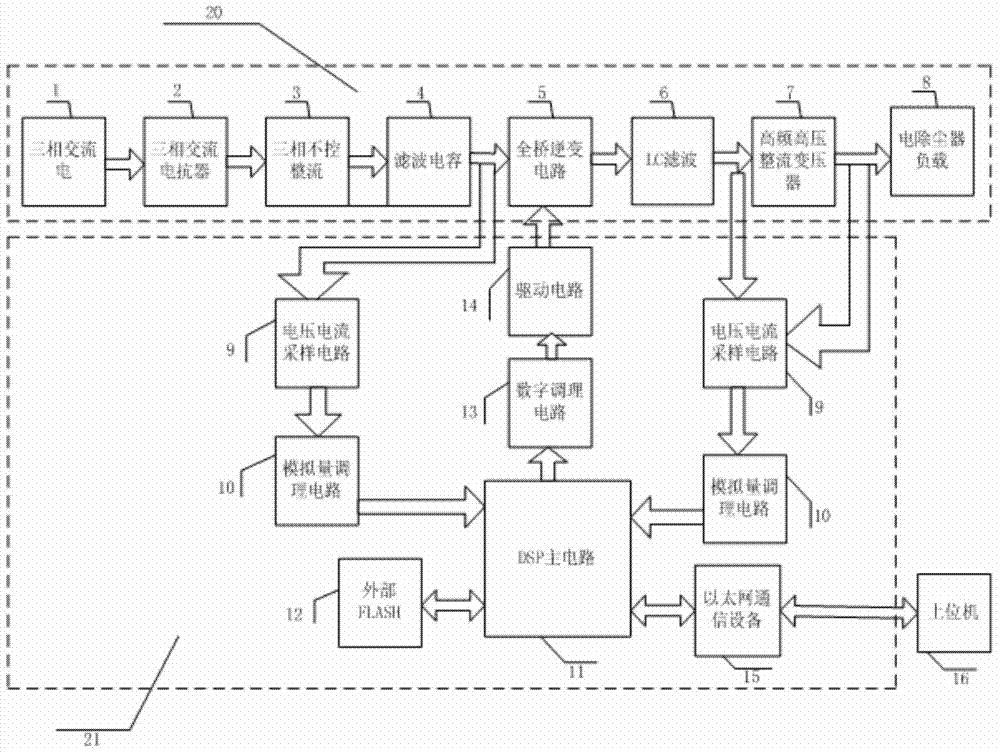

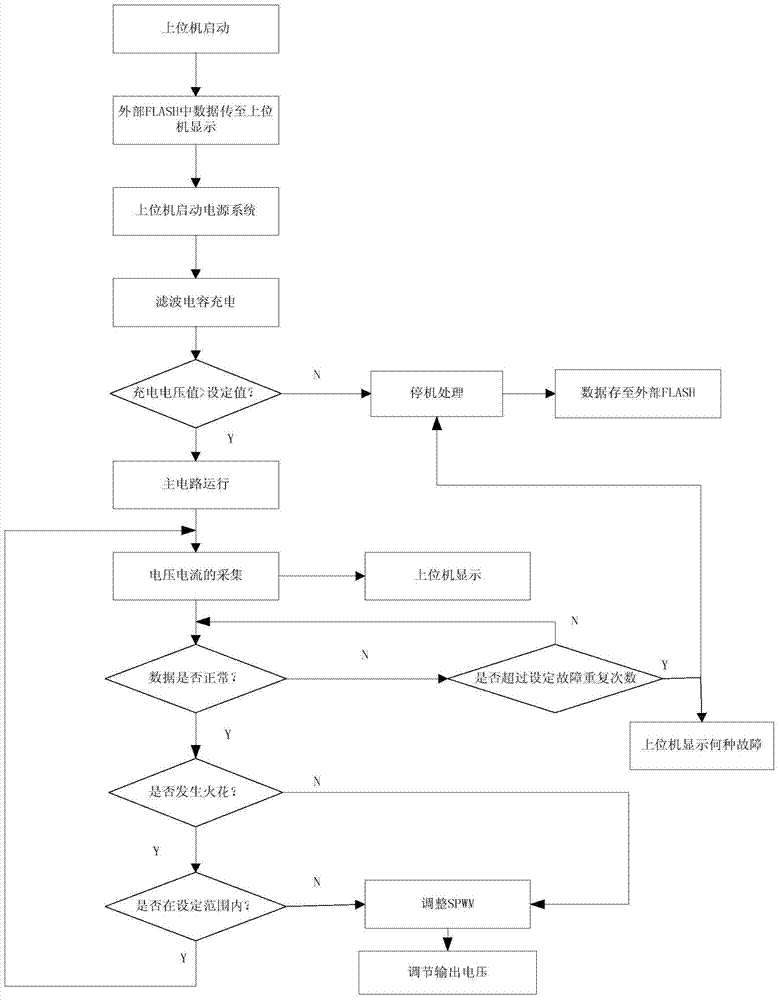

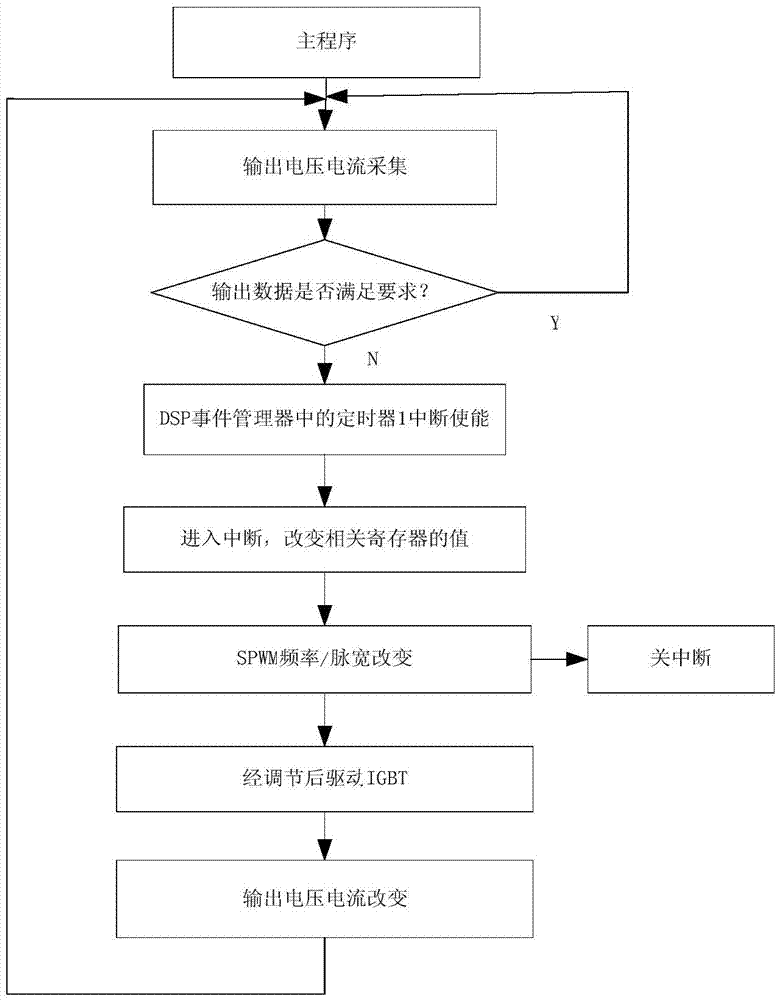

High-frequency and high-voltage electrostatic precipitation power supply

InactiveCN103611632AReduce shockMaterial requirements are highElectric supply techniquesFull bridge inverterElectrostatic precipitator

The invention discloses a high-frequency and high-voltage electrostatic precipitation power supply which comprises a main circuit and a control circuit of the power supply system, as well as an upper computer, wherein the main circuit of the power supply system comprises a three-phase alternating current reactor, a three-phase uncontrolled rectifier, a filter capacitor, a full-bridge inverter circuit, an LC filter and a high-frequency and high-voltage rectifier transformer; the control circuit of the power supply system comprises a voltage and current sampling circuit, an analog quantity conditioning circuit, a digital conditioning circuit, a drive circuit, a DSP (Digital Signal Processor) main circuit, an Ethernet communication facility; a collected voltage or current is sent to the DSP main circuit after being conditioned by the analog quantity conditioning circuit, on the one hand, the DSP chip is used for handling and controlling the operation of the control system according to collected data, on the other hand the DSP chip generates an SPWM (Sinusoidal Pulse Width Modulation) wave which is processed by the digital conditioning circuit and the drive circuit so as to control the turn-on and turn-off of the full-bridge inverter circuit. A voltage wave, which is output after the SPWM wave is used for controlling the full-bridge inversion, is filtered by the LC to form a sine wave which has less harmonic components and causes less impact on the high-frequency rectifier transformer.

Owner:JIANGSU UNIV OF SCI & TECH

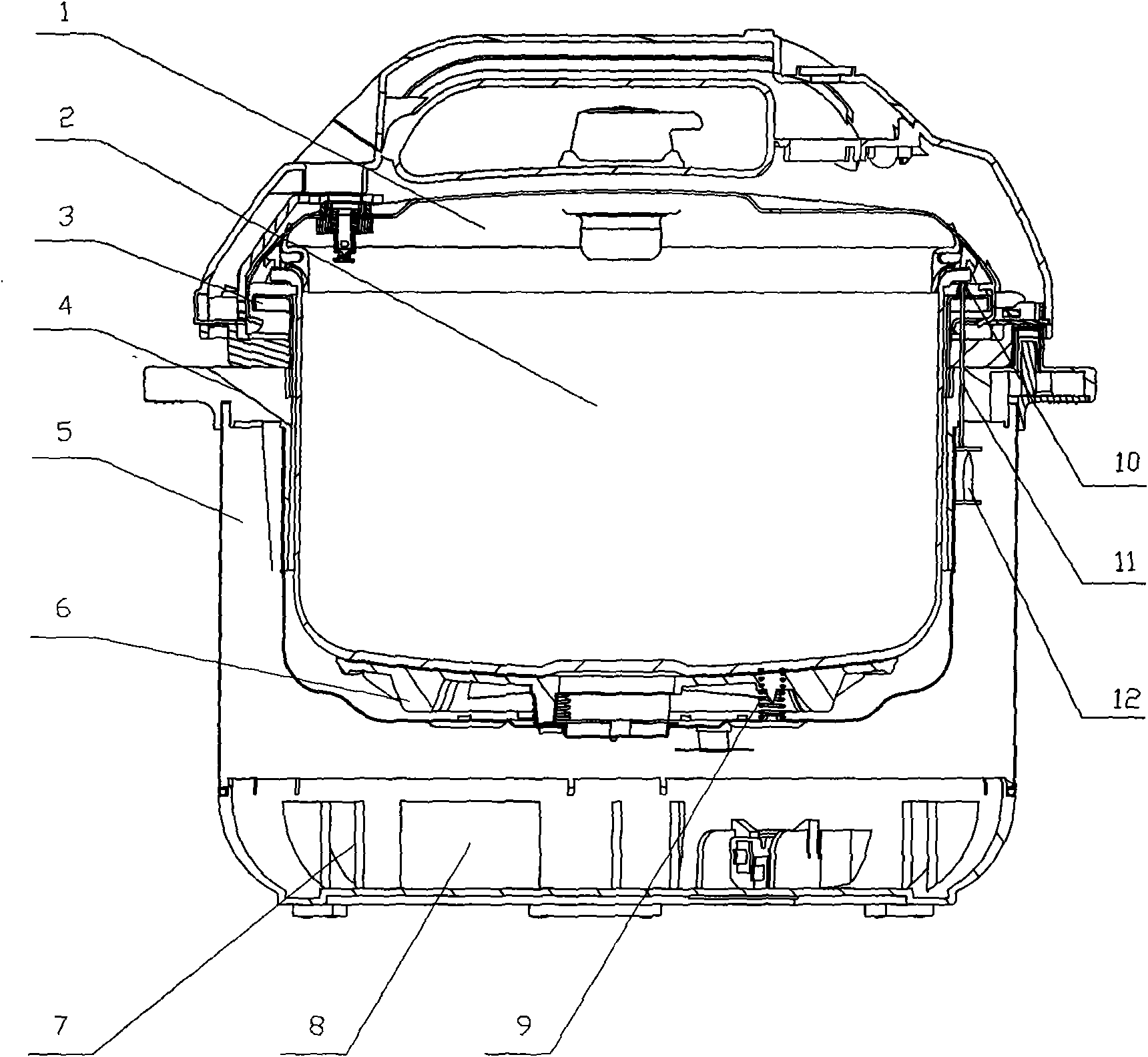

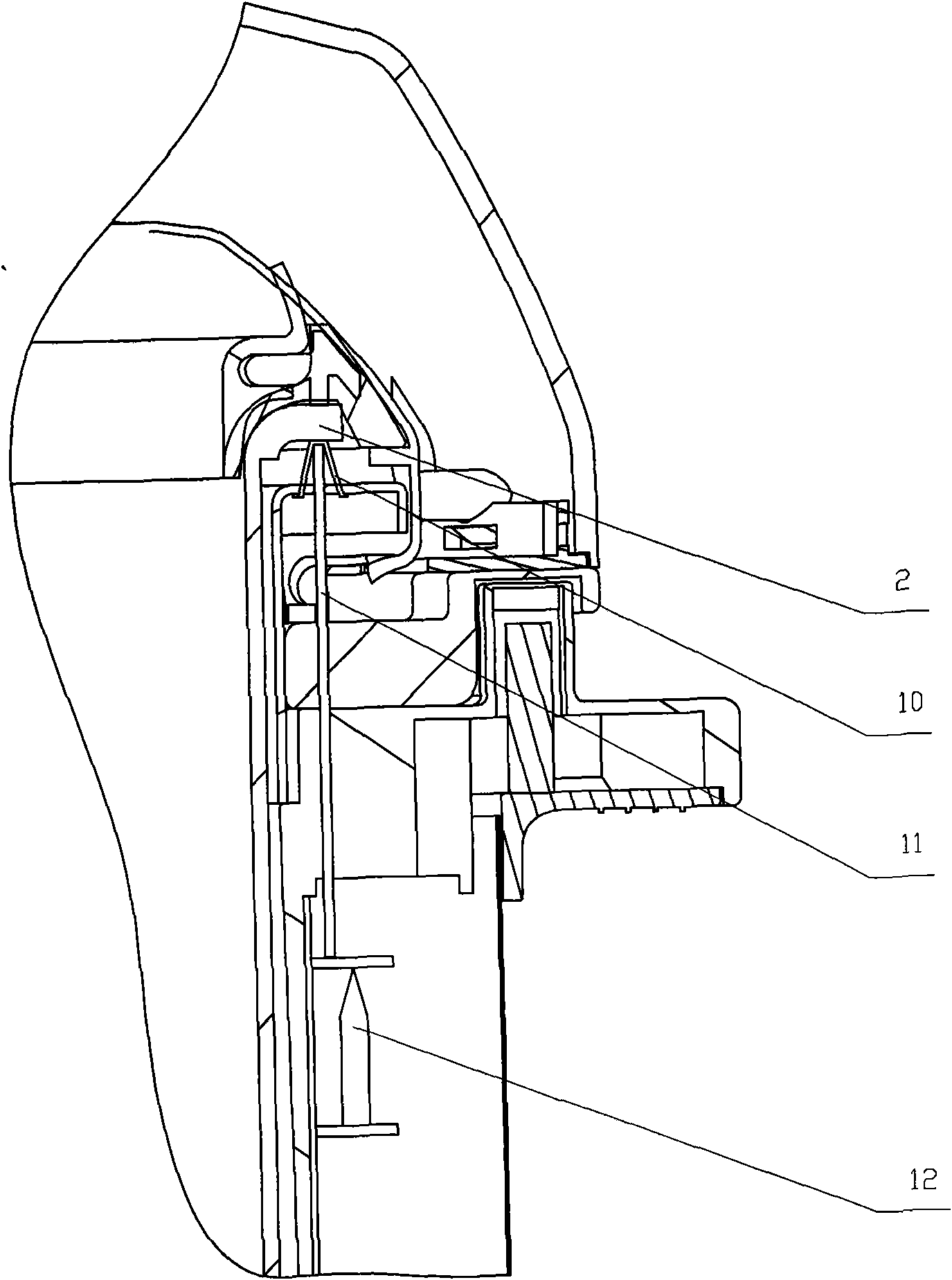

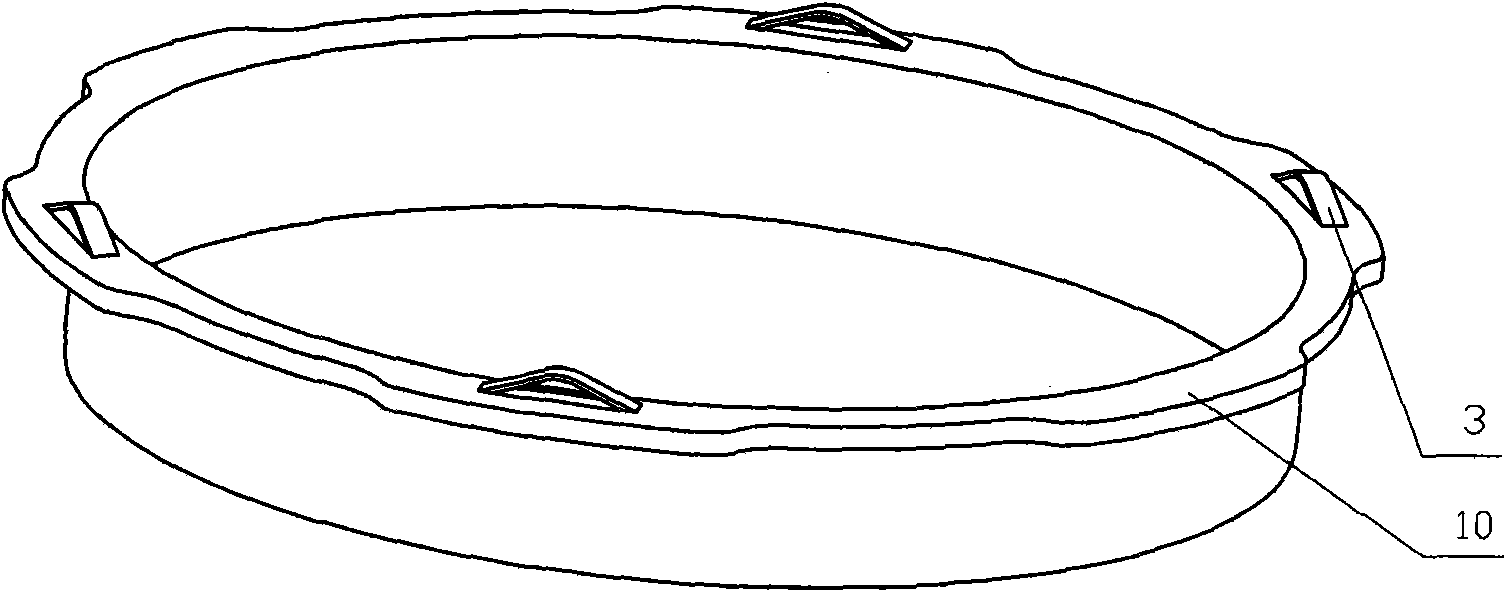

Pressure control structure of pressure cooking appliance

The invention provides a pressure control structure of a pressure cooking appliance, belonging to the technical field of pressure cooking appliances. The structure comprises a pot cover, an external pot, an internal pot, a detecting and collecting part for detecting the displacement amount, and an electric control device for controlling the electric heater according to the information of the detecting and collecting part, the structure is characterized in that the pot cover is buckled to the internal pot through pot teeth; an elastic member is arranged between the pot tooth surface of the opening part of the external pot and the combination surface of the opening part of the internal pot; a displacement linking device is arranged below the elastic member or the internal pot; the detecting and collecting part is located on the lateral part or the bottom of the external pot; the displacement information of the elastic member or the pot body is transmitted to the electric control device by the detecting and collecting part. For the prior art, requirement on the material of the elastic pot teeth is high and cost is increased; in the invention, the pot opening surface is equipped with the elastic member so as to control the pressure correctly, and the strength of the buckling part of the original pot tooth is not change; besides, by using the elastic member as the support part of the internal pot, the bottom of the external pot does not need to bear pressure, the manufacturing cost is reduced, and the processing difficulty is obviously reduced.

Owner:ZHEJIANG SHAOXING SUPOR DOMESTIC ELECTRICAL APPLIANCE CO LTD

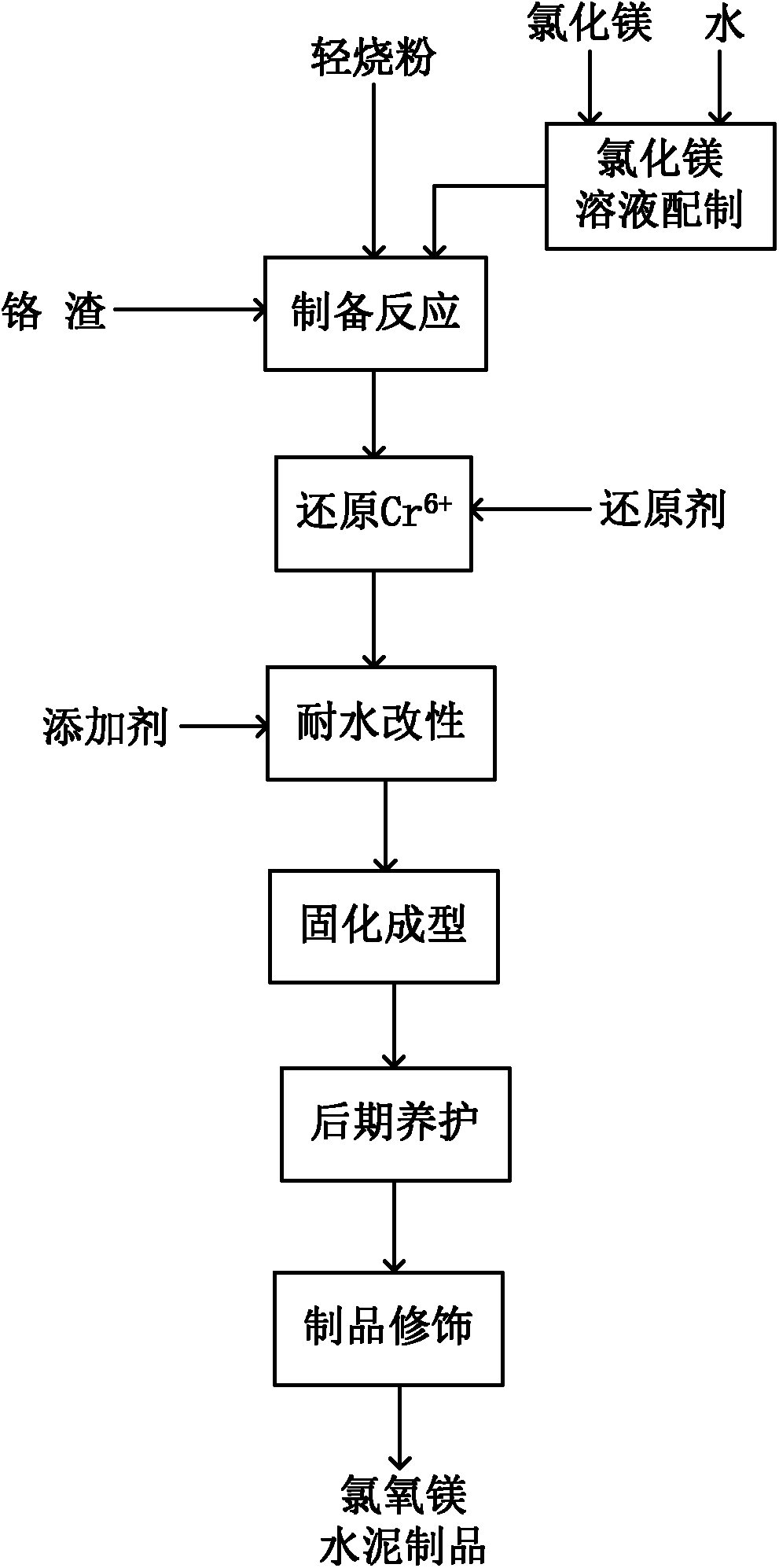

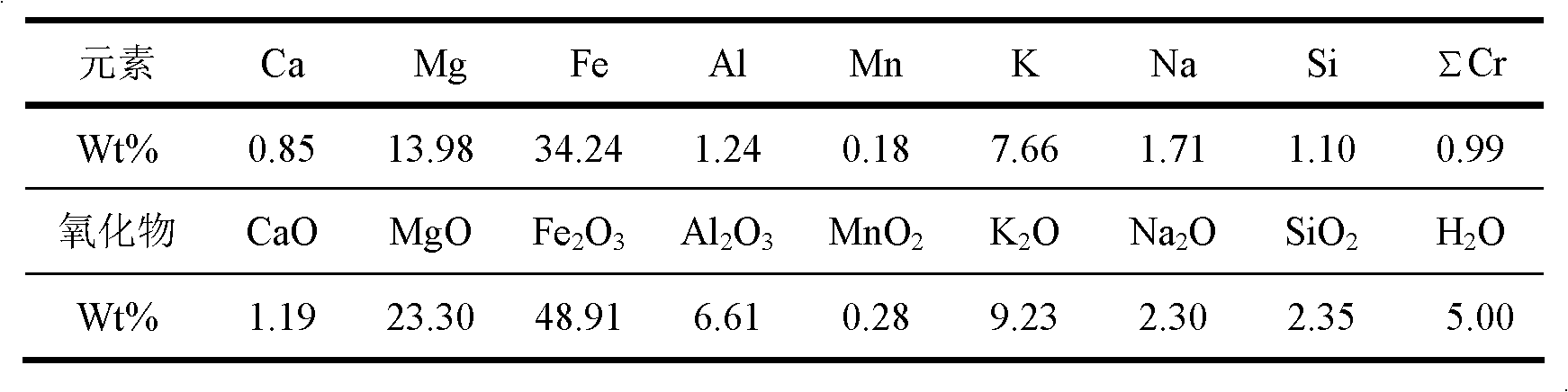

Method for preparing magnesium-oxy-chloride cement by utilizing chromium slag produced through salt sub-melting technology

The invention provides a method for preparing magnesium-oxy-chloride cement by utilizing chromium slag produced through a salt sub-melting technology. The method is characterized in that based on the characteristic that the chromium slag produced through the salt sub-melting technology is rich in magnesium oxide, the chromium slag can be used for replacing a part of magnesite light burning powder, thereby reducing the preparation cost of the magnesium-oxy-chloride cement; toxic hexavalent chromium in the chromium slag is reduced by utilizing ferrous iron, thereby eliminating the potential safety hazard; chromium slag produced through the salt sub-melting technology is rich in iron and can generate ferric hydroxide gel when used for preparing the magnesium-oxy-chloride cement, so that the compactness of products can be improved and then the wear resistance and the strength of the products can be further increased; and a modifier is added so as to improve the properties of the products, obtain a good water-resisting effect and eliminate the defects that the products are rimed and halogenated easily. During the preparation of the magnesium-oxy-chloride cement by utilizing the chromium slag produced through the salt sub-melting technology, neither strong acid nor strong base is involved, the method is carried out at normal temperature and normal pressure, the requirements on equipment materials are not high, the utilization rate of raw materials is high, the technological process is simple, and the method is a novel method for preparing the magnesium-oxy-chloride cement and recycling the chromium slag.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

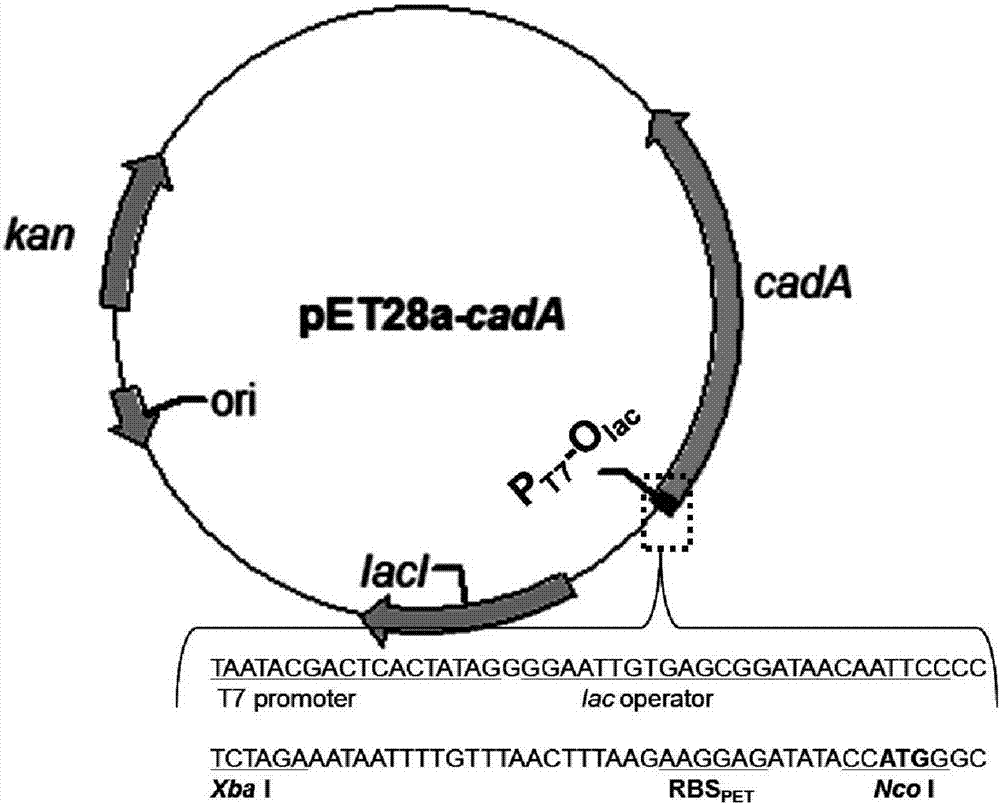

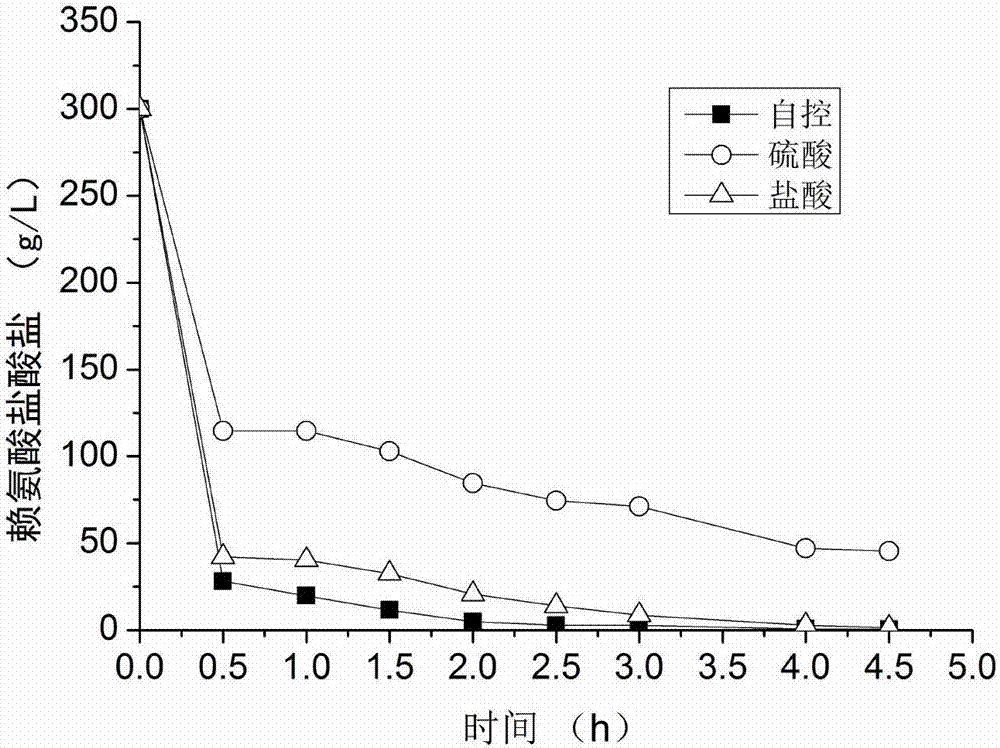

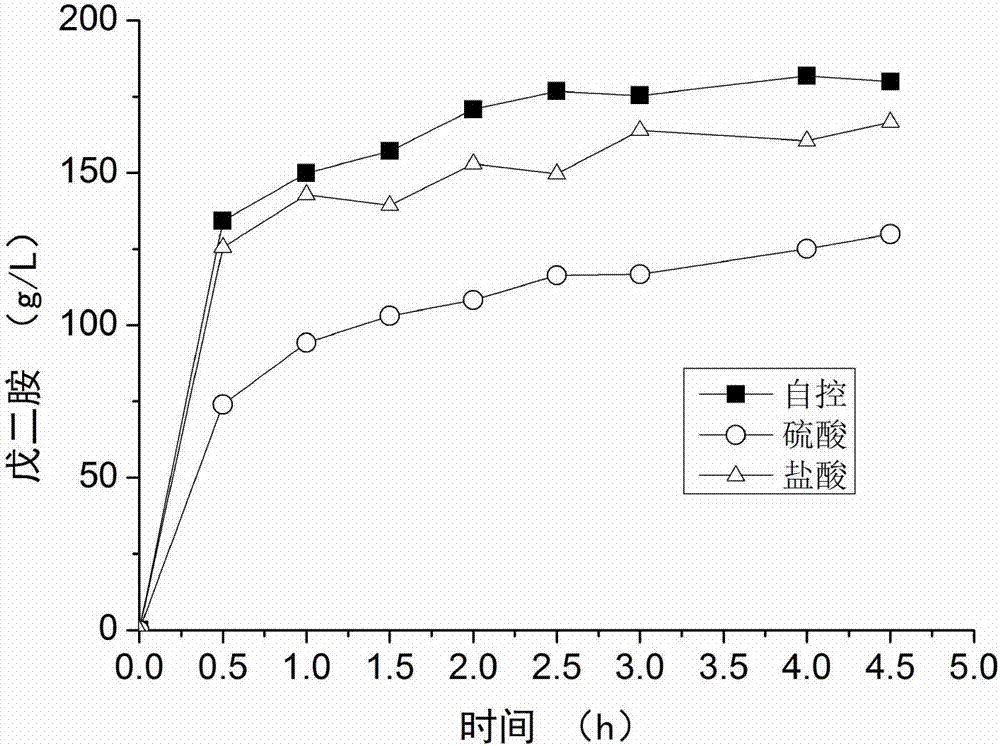

Method for whole-cell catalysis production of pentanediamine through self-control of pH by virtue of byproduct carbon dioxide

InactiveCN107338275AHigh activitySolve problems in actual industrial production applicationsMicroorganism based processesFermentationOperabilityProcessing cost

The invention provides a method for whole-cell catalysis production of 1,5-pentanediamine through self-control of pH by virtue of a byproduct carbon dioxide. Whole-cell catalysis production of the pentanediamine is controlled by the method in which pH of whole-cell catalysis liquid is subjected to self-regulation by virtue of the catalysis byproduct CO2 and non-aeration is adopted. With the application of the pH self-control and non-aeration method provided by the invention, the catalysis production of the pentanediamine can be implemented efficiently, and in addition, adjuvant cost and waste gas processing cost in the production of the pentanediamine can be reduced, a process controlling procedure can be simplified, equipment investment can be reduced and the operability of a production process can be improved. The technique (the method) provided by the invention is practically applicable to large-scale industrial production of the 1,5-pentanediamine; and the technique is quite high in practicability and applicability.

Owner:HEILONGJIANG EPPEN NEW MATERIALS LTD

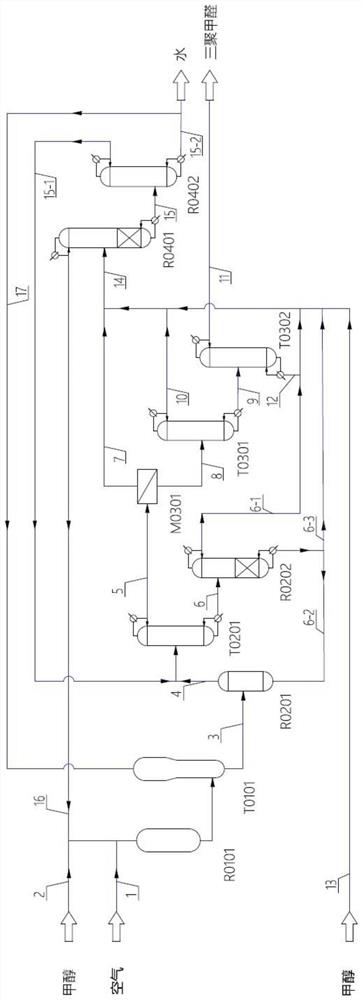

Process for preparing trioxymethylene by taking methanol as raw material

ActiveCN111808067AReduce production rateLarge energy recoveryOrganic chemistryCatalytic transformationPolyoxymethylene

The invention discloses a process for preparing trioxymethylene by taking methanol as a raw material. The process comprises the following steps of: preparing concentrated formaldehyde with the concentration of over 50 percent by taking methanol, and methanol and methylal produced by catalytic conversion in a recovery section as raw materials; synthesizing the concentrated formaldehyde into trioxymethylene under the catalytic action of a solid acid, subjecting a formaldehyde aqueous solution containing trioxymethylene to rectification and membrane coupling process for purifying, and separatingimpurities out to obtain pure trioxymethylene. According to the process disclosed by the invention, the generation amount of dilute aldehyde is reduced, the separation energy consumption is reduced, the impurity content of trioxymethylene is reduced, the utilization rate of raw materials is increased through catalytic conversion and circulation of dilute aldehyde and byproducts, and long-period stable operation of trioxymethylene production can be realized.

Owner:CHINA CHEM TECH RES INST +1

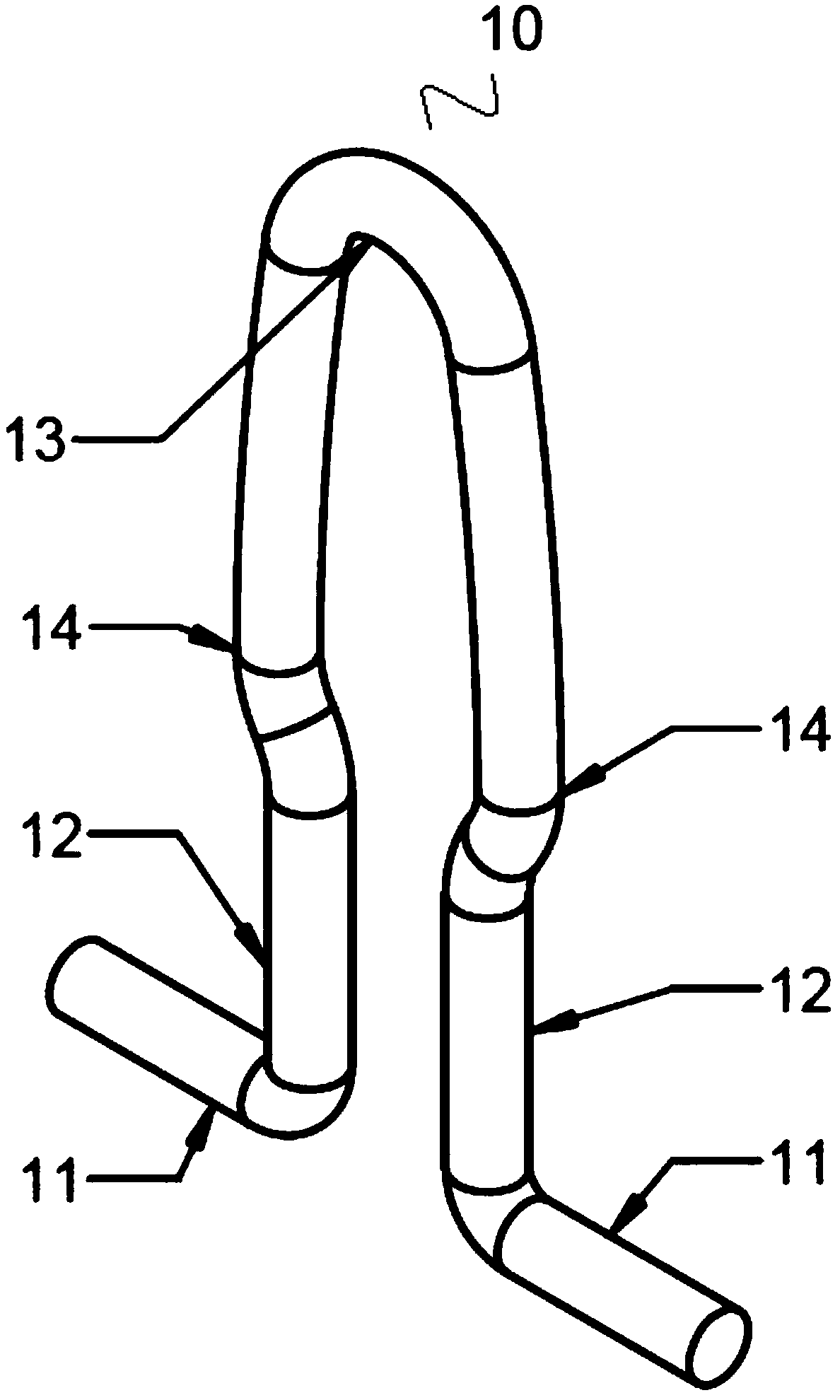

Preparation method for heat exchange tube used for extracting temperature of sewage

InactiveCN102240898AImprove heat transfer efficiencyUniform densityNon-electric welding apparatusWork in processRoll forming

The invention relates to a preparation method for a heat exchange tube used for extracting temperature of sewage. The preparation method is characterized by comprising the following steps: (1) loading a stainless steel coiled plate utilized as a raw material by using an uncoiling machine; (2) guiding the plate from the uncoiling machine to enter into a plate leveling machine and leveling the plate; (3) carrying out roll forming the plate from the plate leveling machine six times and then forming; (4) guiding the plate, which is subjected to roll forming, to enter into a cutting machine, and then cutting the plate according to a technical demand; (5) performing the forming combination prior to roll-welding on a semi-finished product of the heat exchange tube, which is formed in the step (4), by a spot-welding machine according to the technical demand; (6) performing rolling grinding welding on the welding part of the heat exchange tube from the step (5) by a roll grinding welding machine according to the technical demand; and (7) utilizing a reshaping machine to reshape the heat exchange tube which is formed after being welded in the step (6). The heat exchange tube prepared by using the preparation method has the thickness of 1.5-2 millimeters and has the characteristics that the tube wall is thin, the heat exchange effect is good, the welding can be limitlessly prolonged according to an onsite condition, the thickness of welding spots is uniform, and the mounting and maintaining are convenient.

Owner:杨铁君

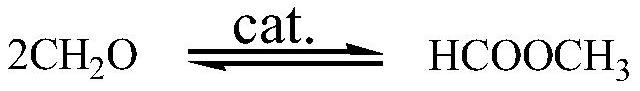

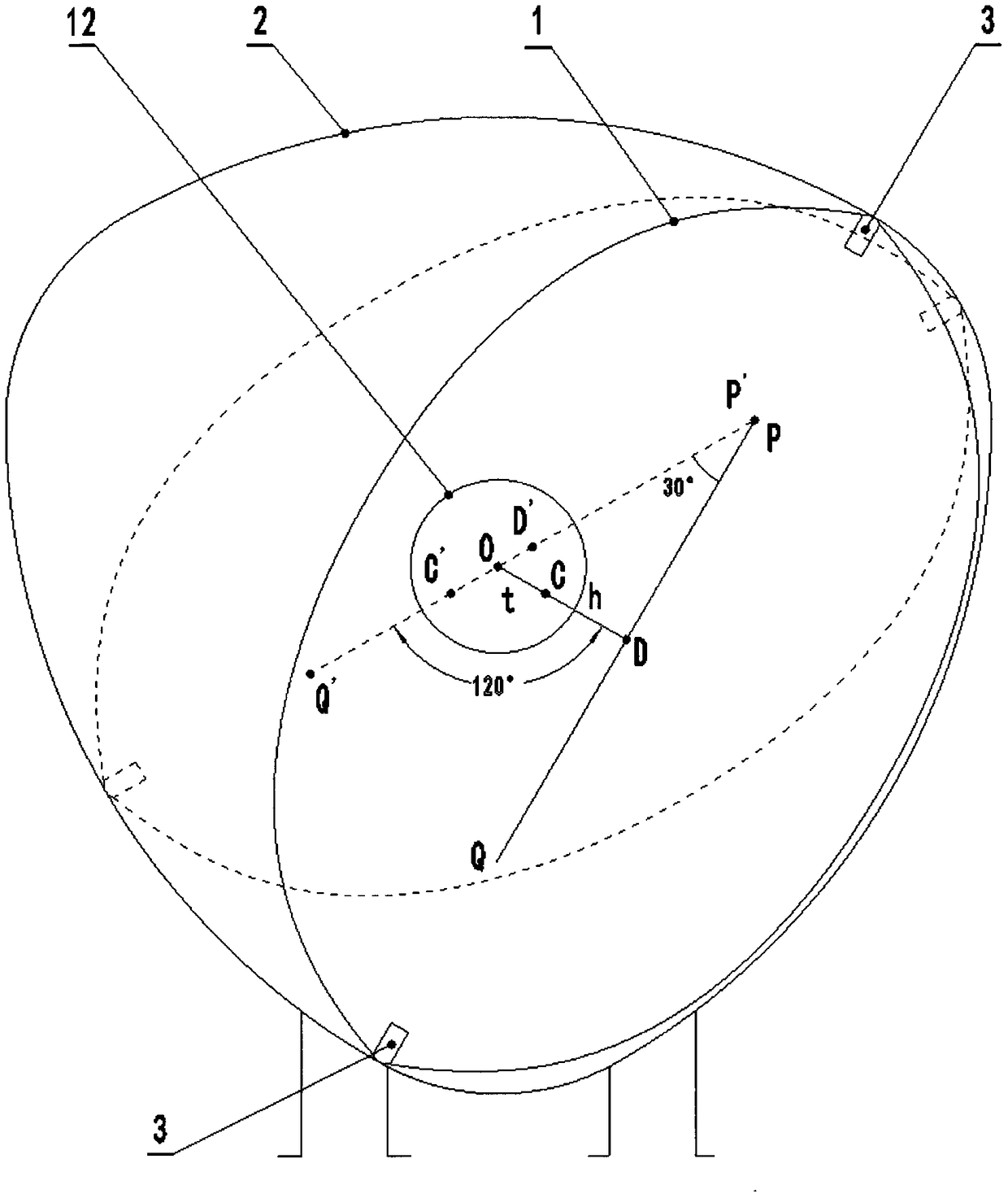

Three-stroke inner-cooling rotor engine

PendingCN108571381AReduce power lossImprove efficiencyInternal combustion piston enginesSpecific gravityPiston

The invention relates to a three-stroke inner-cooling rotor engine, and in particular relates to a three-stroke inner cooling rotary piston internal combustion engine. The three-stroke inner cooling rotary piston internal combustion engine is composed of parts: an air cylinder, a piston, a main shaft, a planetary crankshaft, a planetary gear pair, a piston gear pair, an electric turbocharger, an oil atomizer, sparking plugs and the like. When the main shaft rotates, the elliptical piston is driven to carry out planetary rotary wheel rotation in the triangular air cylinder under transmission ata special speed ratio of the planetary crankshaft and two inner gear pairs to finish working circle of the internal combustion engine. The piston can divide the air cylinder into two air cylinder volumes. When one air cylinder volume finishes one working cycle of the internal combustion engine, the other air cylinder volume finishes an air cooling process in the primary air cylinder. The three-stroke inner-cooling rotor engine is free of complicated gas distributing mechanisms, is simple in structure, small in size, large in power proportion and good in torque smoothness, overcomes the defectof cylinder cracks, and is suitable for being used as an air cooling internal combustion power device.

Owner:王安惠

Method for refining acetylene

ActiveCN104230629AOperating temperature and pressure are easy to operate and controlMild conditions for absorption and regenerationAbsorption purification/separationSolventZero emission

The invention provides a method for refining acetylene, wherein a solvent is used for refining and removing impurities. The method is characterized in that the solvent is selected from one or more of liquid paraffin with the boiling range of 185-250 DEG C, distillate oil at vacuum side stream with the boiling range of 320-400 DEG C, distillate oil at second atmospheric side stream with the boiling range of 200-260 DEG C and distillate oil at first atmospheric side stream with the boiling range of 170-230 DEG C. The method provided by the invention is free from three-waste emission, and the DMY (dihydromyricetin) solvent in a solvent method can be recycled, so that the solvent is zero emission. The purity of recovered advanced alkyne is high and reaches over 99%, and the alkyne can be used as a fuel. The purity of acetylene purified is high, the content of impurities is lower than 0.05 %, and the loss of acetylene is low and is less than 0.5%.

Owner:SINOPEC SICHUAN VINYLON FACTORY +1

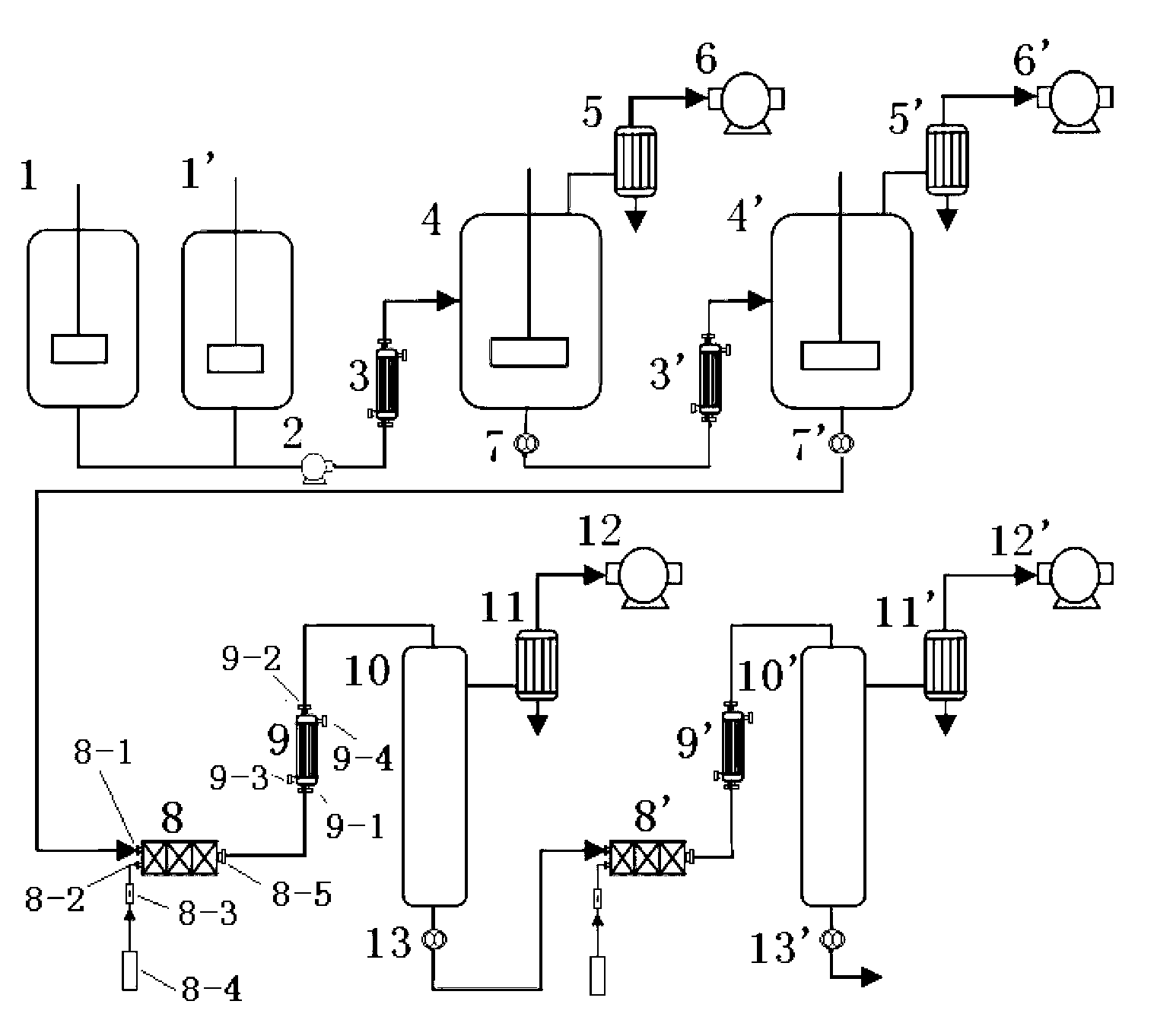

A system for continuously preparing polyoxymethylene dimethyl ether with methanol as the initial reaction raw material

ActiveCN104003855BSimple processSimplify investmentOrganic chemistryOrganic compound preparationOligomerSewage

The invention discloses a system for continuously preparing polymethoxy dimethyl ether by using methanol as an initial reaction raw material, which mainly comprises a formaldehyde preparation unit, a methylal preparation unit and a polymethoxy dimethyl ether preparation unit, wherein the formaldehyde preparation unit is mainly used for oxidizing the raw material methanol into a formaldehyde solution under the action of a catalyst; the methylal preparation unit is used for reacting part of the formaldehyde solution with methanol under the action of a solid acidic resin catalyst to prepare methylal; and the polymethoxy dimethyl ether preparation unit is used for respectively carrying out condensation reaction on the methanol and methylal with the formaldehyde solution under the action of an ionic liquid catalyst to prepare the polymethoxy dimethyl ether, and separating and purifying the reaction product to obtain the polymethoxy dimethyl ether product. Compared with the trioxymethylene or oligomer formaldehyde route, the system has the advantages of simple process and low energy consumption, is simple to operate, implements recovery treatment of sewage on the premise of cyclic recovering the intermediate product, and thus, is very suitable for large-scale industrial production.

Owner:上海中信国安化工科技研发有限公司

Heat radiator perforation anchor fixing device

InactiveCN108419360AFirmly assembledReduce manufacturing costPrinted circuit aspectsCircuit thermal arrangementsTransverse grooveLocking mechanism

The invention discloses a heat radiator perforation anchor fixing device, which comprises a heat radiator, a PCB board and a heat radiator locking mechanism. The heat radiator comprises a plurality ofheat radiating fins, an upper surface and a lower bottom surface, the heat radiating fins are all fixed to the upper surface, and at least one U-shaped groove and a plurality of transverse grooves are formed between adjacent heat radiating fins. The PCB board comprises a board upper surface, board slot holes and a board lower bottom surface, and each board slot hole comprises a board slot hole short side and a board slot hole long side. The locking mechanism comprises claw anchors, anchor brackets and a Z-shaped spring, each anchor bracket comprises an anchor bracket hole, an anchor bracket opening, an anchor bracket V groove and an anchor bracket top surface, the Z-shaped spring comprises a spring middle portion, spring shoulder portions and spring hooks, the claw anchors penetrate the board slot holes upwards from the board lower bottom surface, the spring hooks fasten tops of the claw anchors, and the Z-shaped spring fix the heat radiator to a heat source. The fixing device has advantages that difficulty in 'mounting leg' assembly is greatly lowered, and reliability in assembly, low part machining requirement and low cost are realized.

Owner:AAVID SHANGHAI SYST

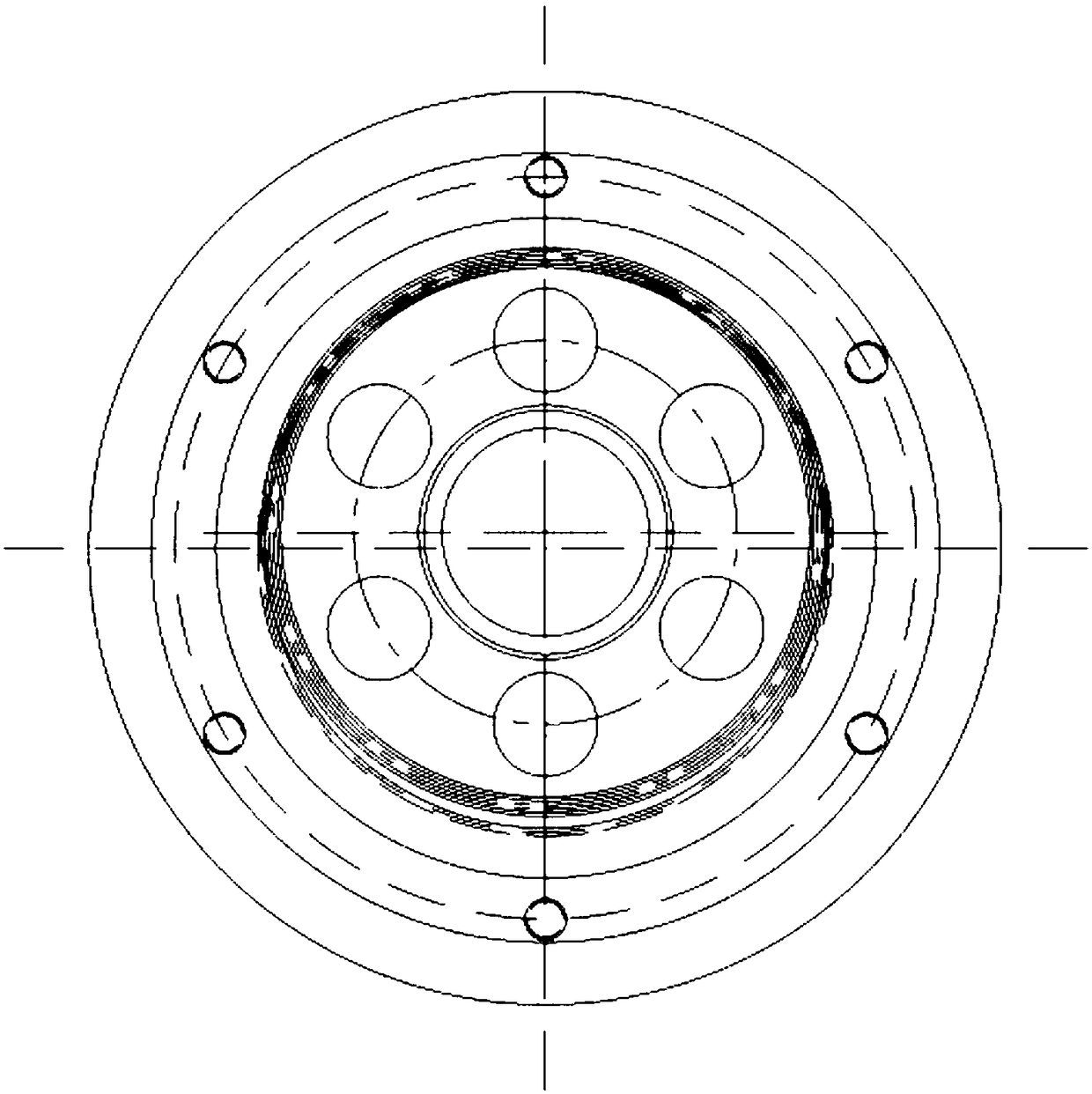

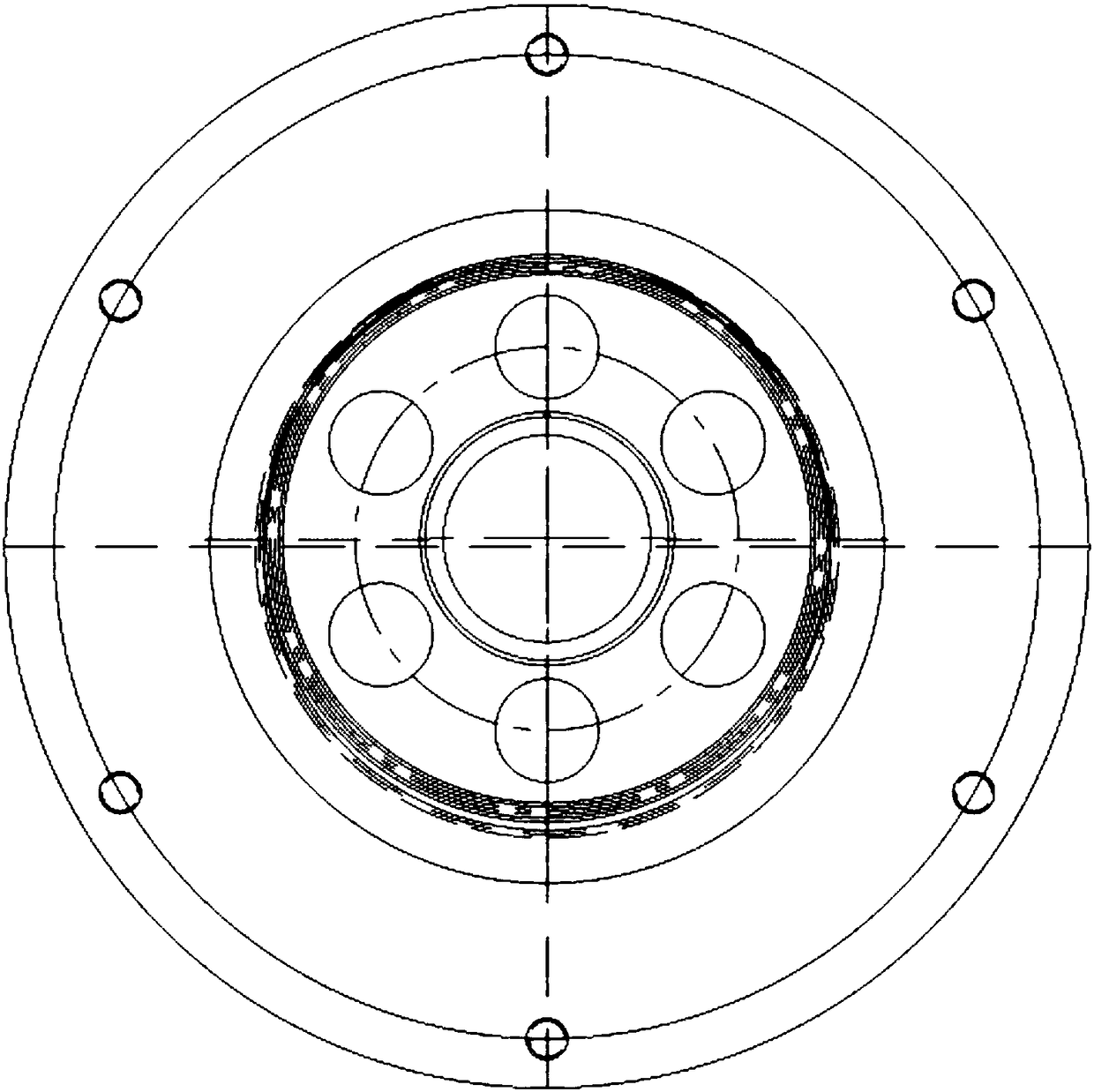

Speed reducer of novel industrial robot

InactiveCN108119615AMaterial requirements are highHigh precision requirementsToothed gearingsMechanical energy handlingMechanical engineeringCrankshaft

The invention provides a speed reducer of a novel industrial robot. The speed reducer includes a motor and a mounting plate for mounting the motor. A fixed inner gear ring is mounted on the mounting plate, a rotating disc is mounted between the fixed inner gear ring and the mounting plate, an annular roller path is arranged between the rotating disc and the fixed inner gear ring and between the rotating disc and the mounting plate respectively, a roll ball is mounted in the annular roller path, the rotating disc is provided with inner teeth, and a driving gear matched with the inner teeth is mounted on an output shaft of the motor. A pressing plate is fixed on the fixed inner gear ring, a movable inner gear ring is mounted between the fixed inner gear ring and the pressing plate, an annular roller path is disposed between the movable inner gear ring and the fixed inner gear ring and between the movable inner gear ring and the pressing plate respectively, and a roll ball is mounted in the annular roller path. A crankshaft is fixed at the center of the rotating disc, a bearing is mounted on the crankshaft, a dual gear is mounted on the bearing, and an external gear of the dual gear is meshed with the movable inner gear ring.

Owner:CHANGSHA ZHIWEI ELECTRONICS TECH CO LTD

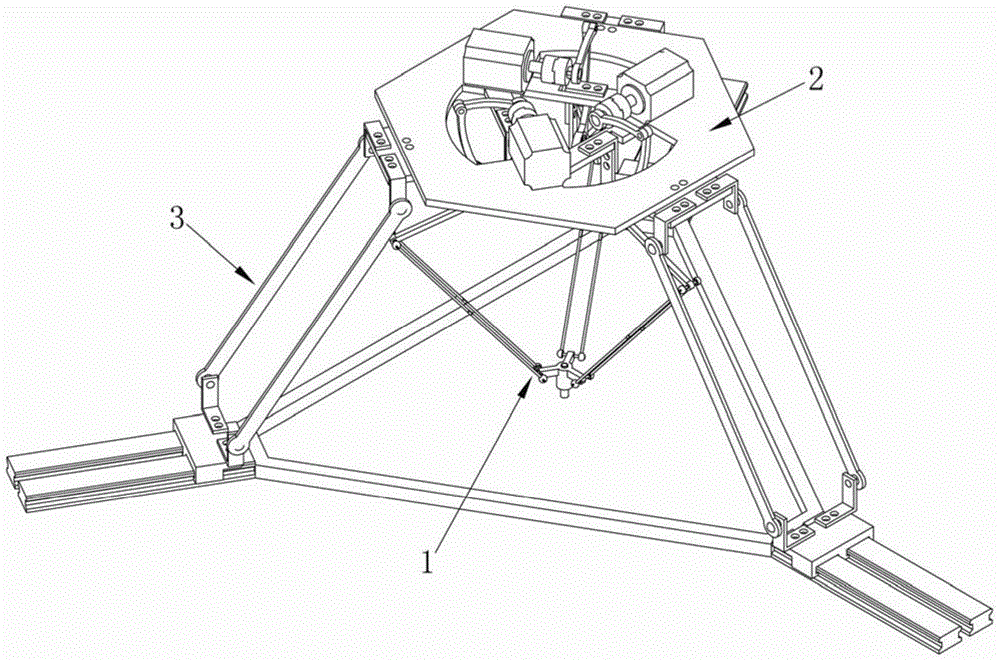

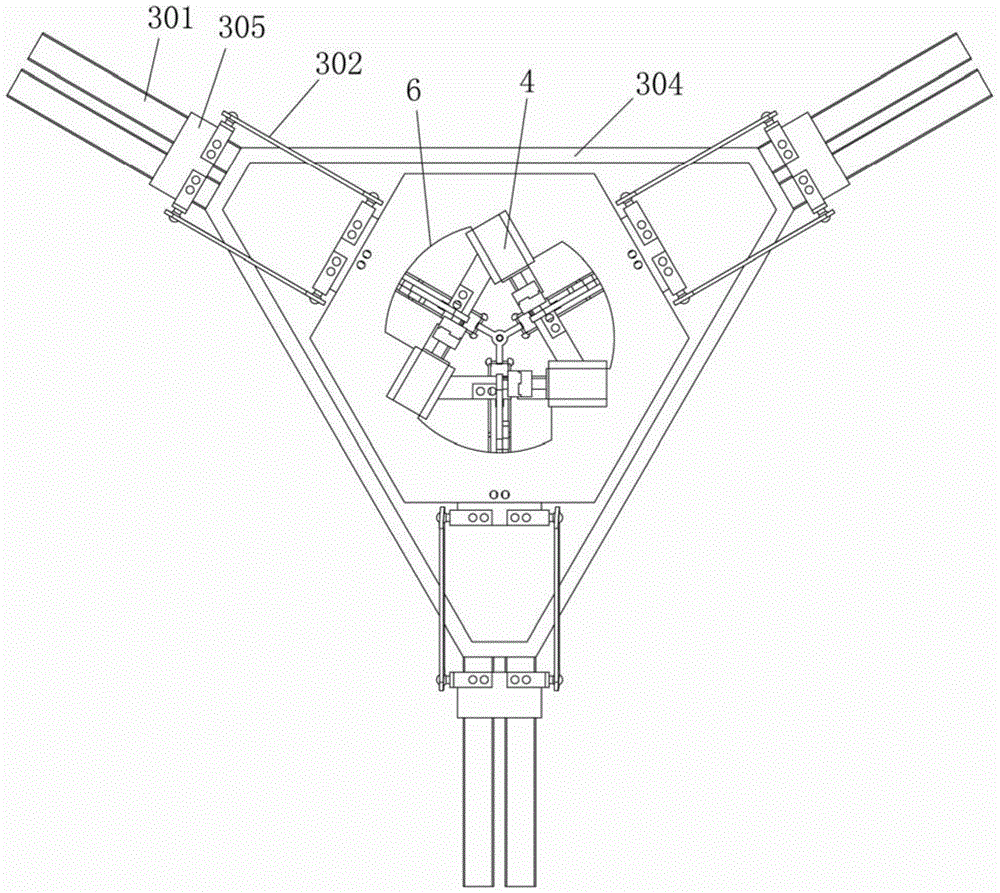

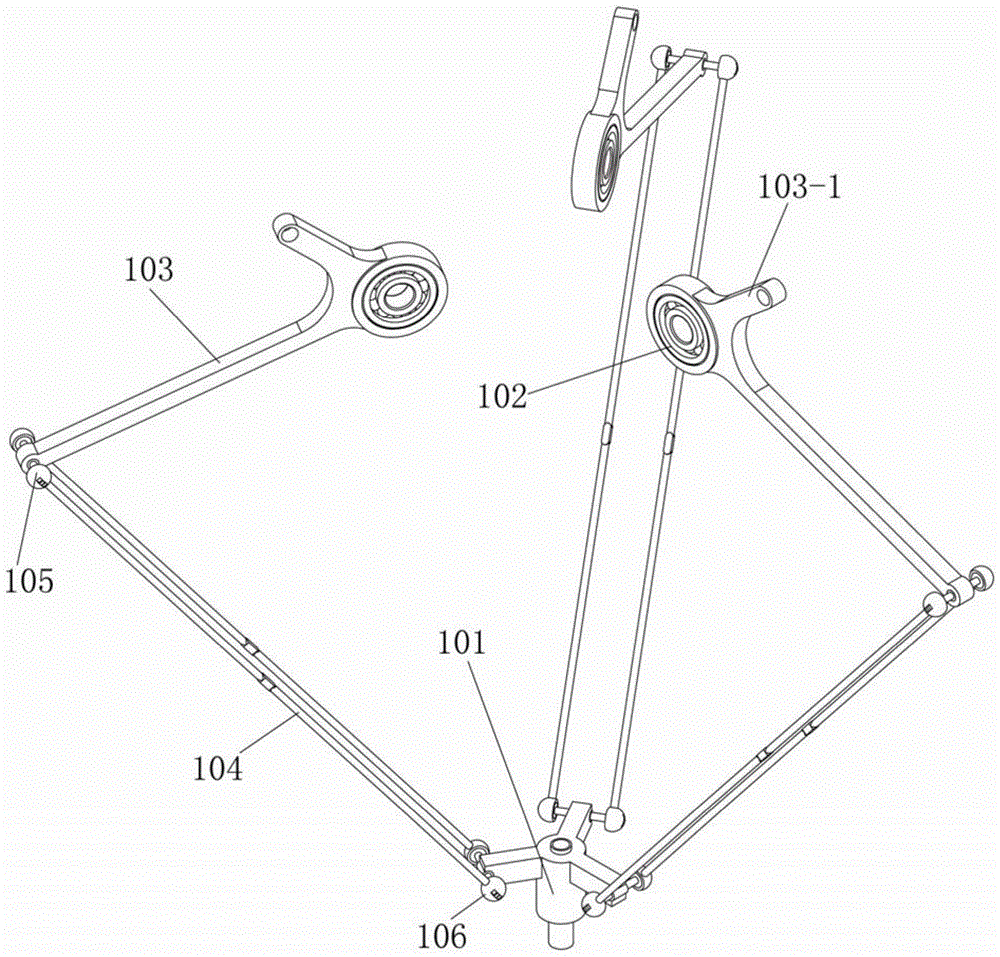

A parallel manipulator with delta structure capable of precise three-dimensional movement

InactiveCN104149096BLarge range of motionImprove the lack of narrow range of motionManipulatorInsertion stentRange of motion

The invention discloses a delta structure parallel manipulator capable of precise three-dimensional movement, comprising a delta-type parallel manipulator body based on a 3-RUU kinematic chain, a carrying main platform, and a main platform support based on a 3-PUU kinematic chain, wherein the The Delta type parallel mechanical mobile phone body is installed on the carrying main platform, and is driven by the servo motor on the carrying main platform through the transmission four-bar mechanism; the carrying main platform is supported by the main platform bracket based on the 3-PUU kinematic chain, and has The space has three degrees of freedom in translation, which can be lifted up and down and moved in a plane. The present invention is based on the 3‑PUU and 3‑RUU kinematic chains at the same time, which can enable the carrying main platform to obtain a spatial range of motion, not only can be raised and lowered, but also can be moved in a plane, and then the end of the second-stage moving platform (Delta type parallel robot body) can be executed. Components) have a larger accessible workspace and flexible workspace.

Owner:SOUTH CHINA UNIV OF TECH

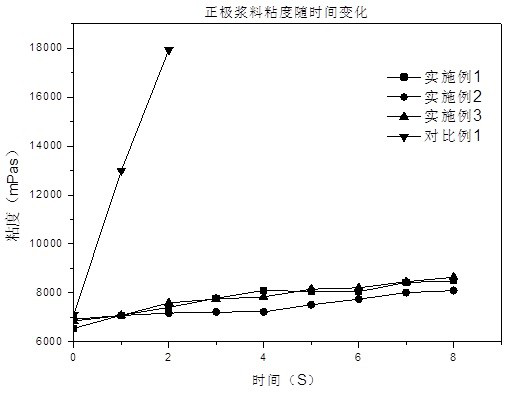

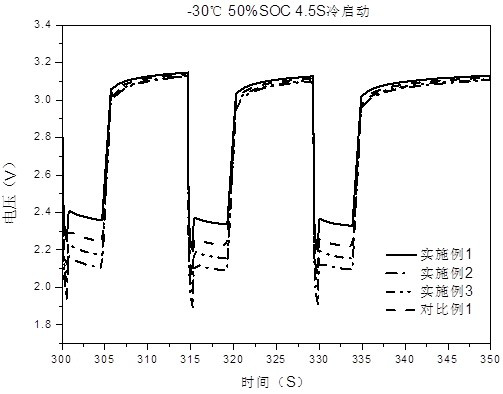

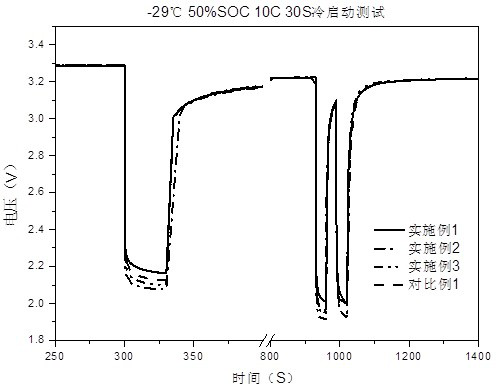

Preparation method of positive electrode slurry suitable for 12V start-stop power supply

InactiveCN113036068APromote depolymerizationMaterial requirements are highElectrode manufacturing processesSecondary cellsLithium iron phosphateElectrical battery

The invention relates to a preparation method of positive electrode slurry suitable for a 12V start-stop power supply, belongs to the technical field of automobile start-stop battery systems, and mainly solves the problems that small-particle-size particles are difficult to disperse and the dispersion time is long when the nanoscale lithium iron phosphate positive electrode slurry is prepared at present. The method is mainly characterized by comprising the following steps: premixing a positive active material, a conductive agent and a binder by using a three-shaft stirrer; adding part of the solvent for wetting; adding part of the solvent for pre-kneading; kneading in a three-shaft stirrer; adding the residual solvent, and diluting to proper viscosity; and vacuumizing and defoaming to obtain the lithium iron phosphate slurry suitable for coating. A high-viscosity kneading process is adopted, a solvent is gradually added into solid powder, the dispersion effect is improved by utilizing the action force that materials are continuously extruded, stretched, folded, sheared and the like under the high solid content, and the preparation method is mainly used for preparing the 12V start-stop power supply positive electrode slurry.

Owner:CAMEL GRP NEW ENERGY BATTERY CO LTD

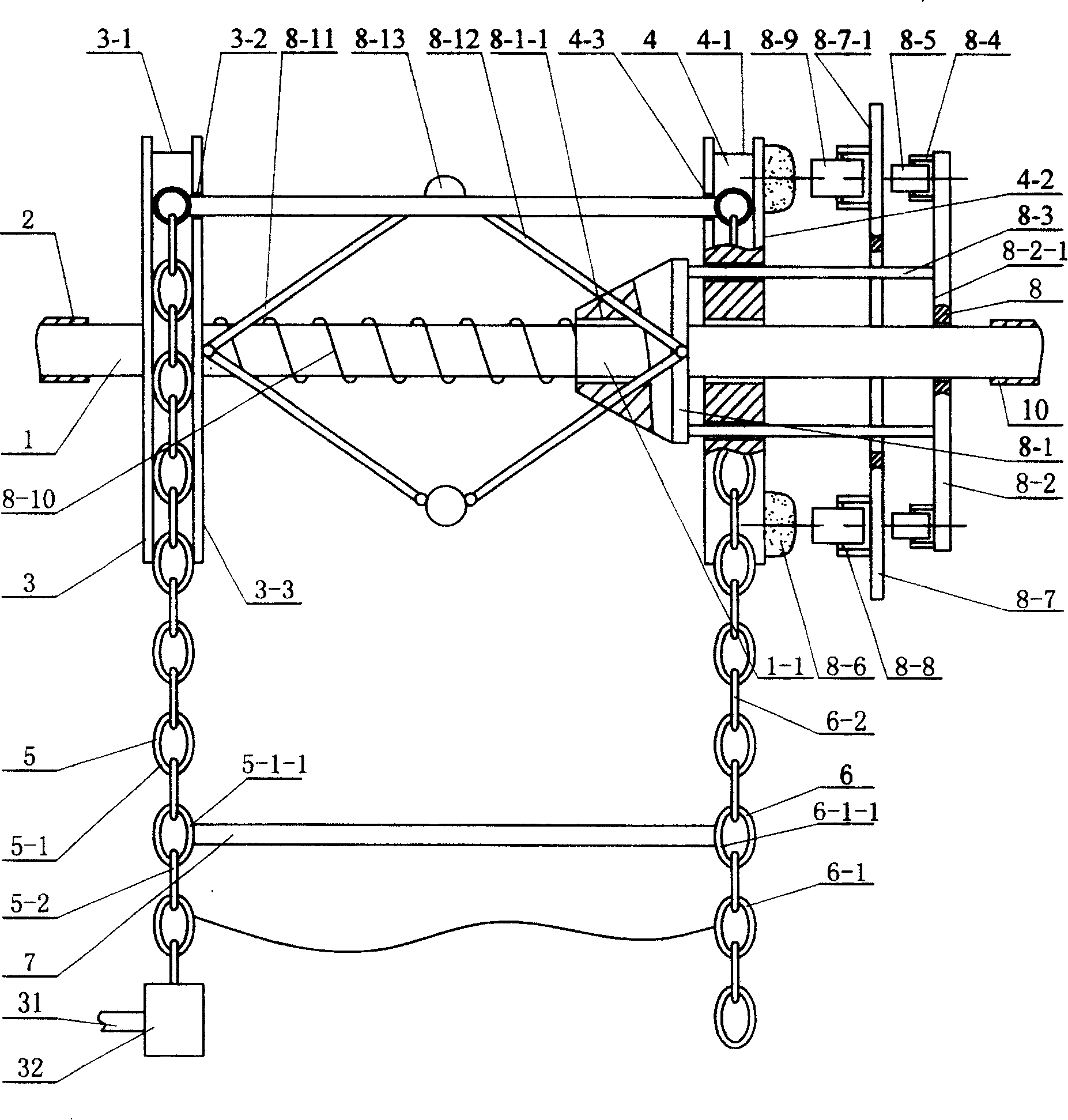

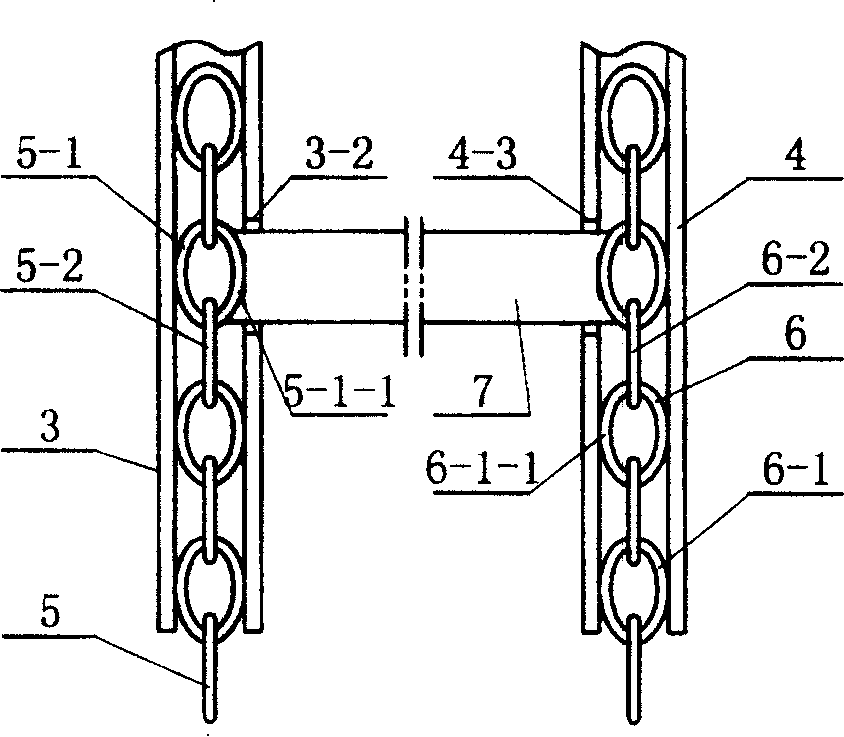

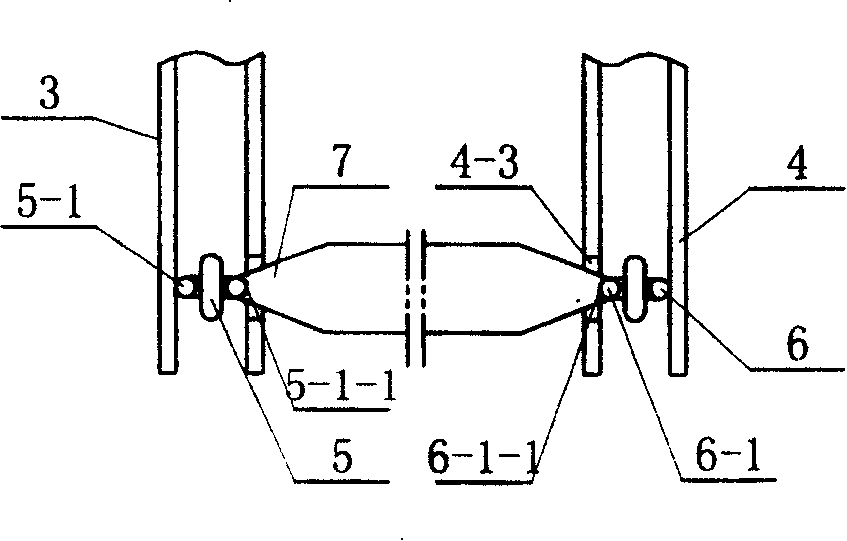

High building life saving device

Owner:高家榕

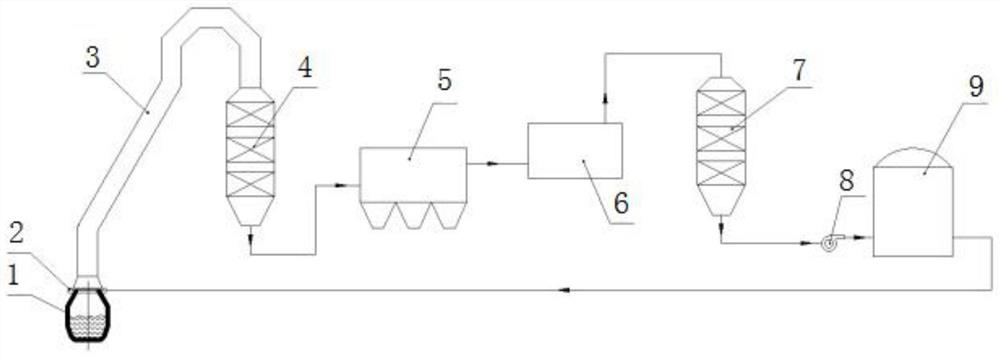

Converter flue gas carbon dioxide recovery system and process

PendingCN114196797ASolve bulkyMaterial requirements are highCarbon compoundsEnergy inputSmoke hoodEnvironmental geology

The invention relates to the field of ferrous metallurgy production, in particular to a converter flue gas carbon dioxide recovery system and process. The carbon dioxide recovery system comprises a first waste heat recovery device, a purification device, a chemical looping combustion device, a second waste heat recovery device and a carbon dioxide storage tank which are sequentially connected through pipelines, and an evaporation cooling flue used for cooling is connected between the first waste heat recovery device and a flue gas outlet of the converter. A furnace mouth smoke hood is further arranged between the smoke outlet of the converter and the evaporative cooling flue, a draught fan is further arranged on the pipeline between the second waste heat recovery device and the carbon dioxide storage tank, and a gas sealing protection device is arranged at the smoke outlet of the converter, so that air suction can be restrained, and low-nitrogen or nitrogen-free smoke is obtained. The converter flue gas is cooled for multiple times before entering the chemical looping combustion device, and the flue gas waste heat is recycled, so that the high requirement on the combustion device caused by overhigh flue gas temperature can be avoided, and meanwhile, the potential safety hazard of oxidation-reduction reaction at high temperature is avoided.

Owner:WISDRI ENG & RES INC LTD

Differential locking mechanism

The invention discloses a differential locking mechanism. The differential locking mechanism comprises a differential and a locking structure. A gear C is fixedly arranged at the end, positioned outside a differential shell, of a planet gear shaft; a sleeve is fixedly arranged at one end of the differential shell; a gear D is arranged on the side, near the differential shell, of the sleeve in a sleeving manner; the gear D is rotationally connected with the sleeve; one end of the gear D is fixedly connected with a gear E; the gear E is rotationally connected with the sleeve; a longitudinal tooth groove is formed in the end, far from the differential shell, of the sleeve; a tooth sleeve is arranged on the tooth groove in a sleeving manner, is engaged with the tooth groove, and can move in the longitudinal direction of the tooth groove; teeth are arranged at one end of the tooth sleeve, and can be engaged with the gear E; an annular groove is arranged outside the tooth sleeve; and a poking fork is movably connected into the groove.

Owner:郭放

Technique for preparing derived fuel from high-moisture domestic waste and municipal sludge

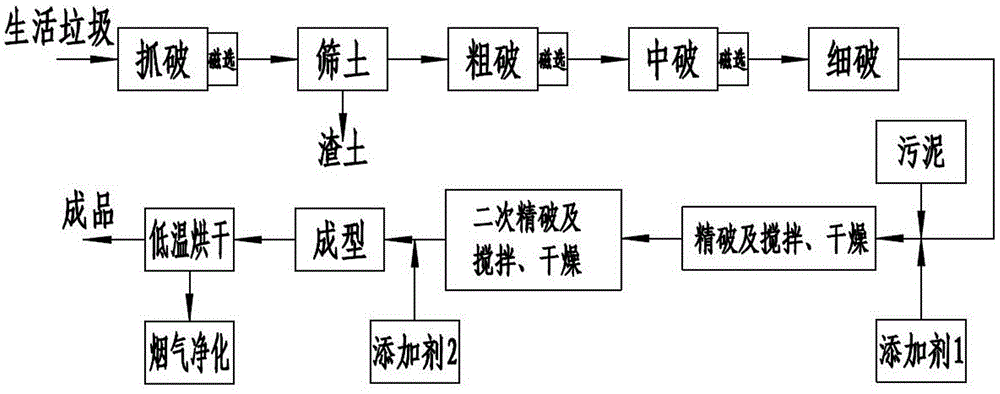

ActiveCN103436321BMaterial requirements are highEffective protectionBiofuelsSolid fuelsMolding machineSludge

The invention discloses an efficient technical process for preparing derived fuel from high-moisture domestic waste and municipal sludge. The technique comprises the following steps: by using domestic waste and municipal sludge as main components, progressively and gradually crushing the domestic waste without manual separation or previously dehydrating and drying the domestic waste and sludge, sequentially adding a certain proportion of additives, carrying out crushing, stirring and drying twice on the mixture by a fine crushing-stirring-molding integrated machine to sufficiently pulverize the domestic waste, and thoroughly mixing the sludge with the domestic waste and additives to carry out modification treatment; and carrying out extrusion molding on the sludge by a molding machine by using the viscosity of the sludge, and finally delivering to a low-temperature drier to carry out baking. The invention achieves the goals of energy saving and zero discharge in the production process.

Owner:桂林聚能环保科技有限责任公司

Technique for preparing derived fuel from municipal sludge and biomass

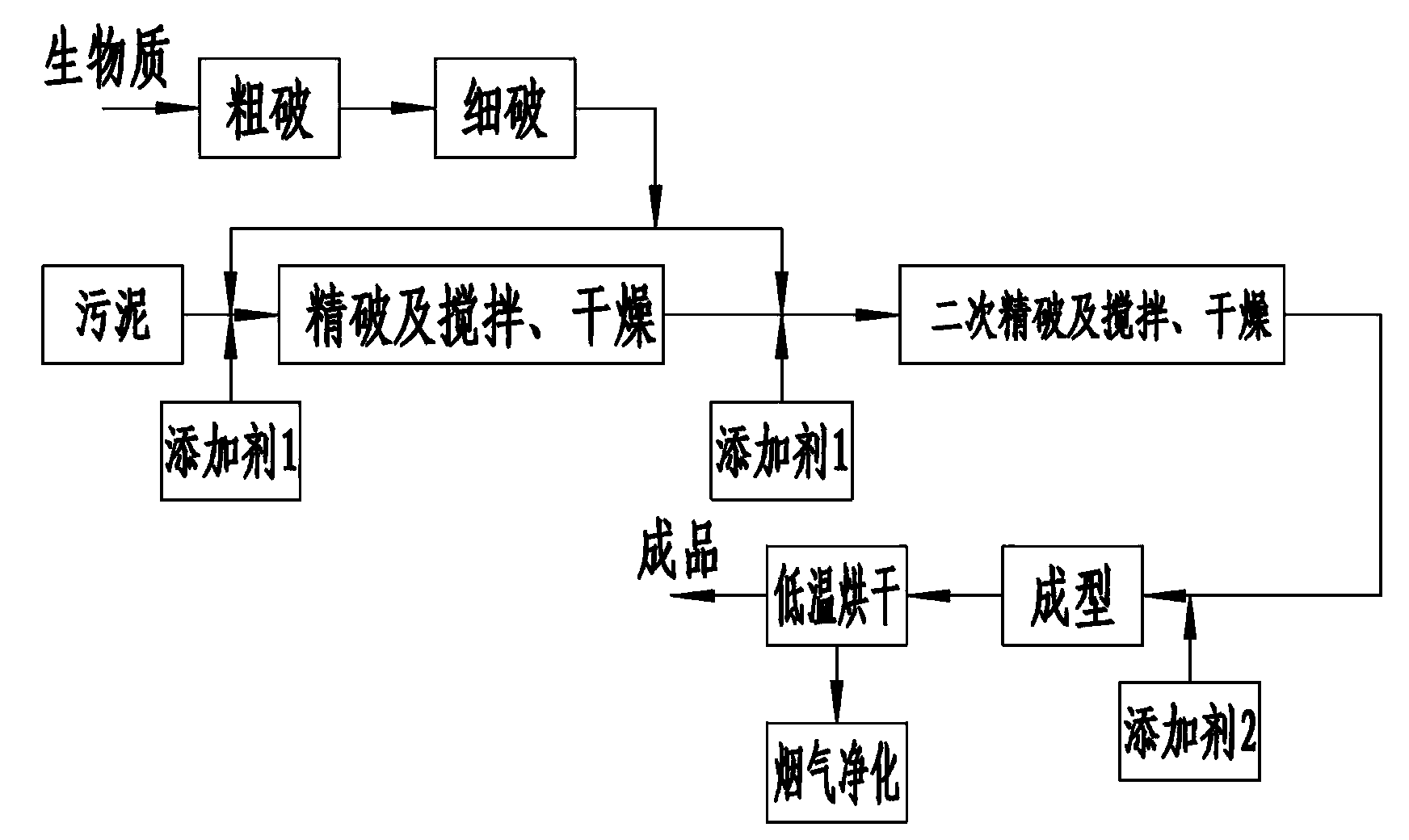

ActiveCN103436318AMaterial requirements are highEffective protectionBiofuelsSolid fuelsMolding machineSludge

The invention discloses a technique for preparing derived fuel from municipal sludge and biomass, which is an energy-saving and efficient industrialized preparation technique. The technique comprises the following steps: previously baking or dehydrating the main component municipal sludge, proportionally adding biomass and additives, carrying out crushing, stirring and drying twice on the mixture by a fine crushing-stirring-molding integrated machine to sufficiently pulverize the biomass, and thoroughly mixing the sludge with the biomass and additives to perform modification treatment; and carrying out extrusion molding on the sludge by a molding machine by using the viscosity of the sludge, and finally delivering to a low-temperature drier to carry out baking. The invention achieves the goals of energy saving and zero discharge in the production process.

Owner:桂林聚能环保科技有限责任公司

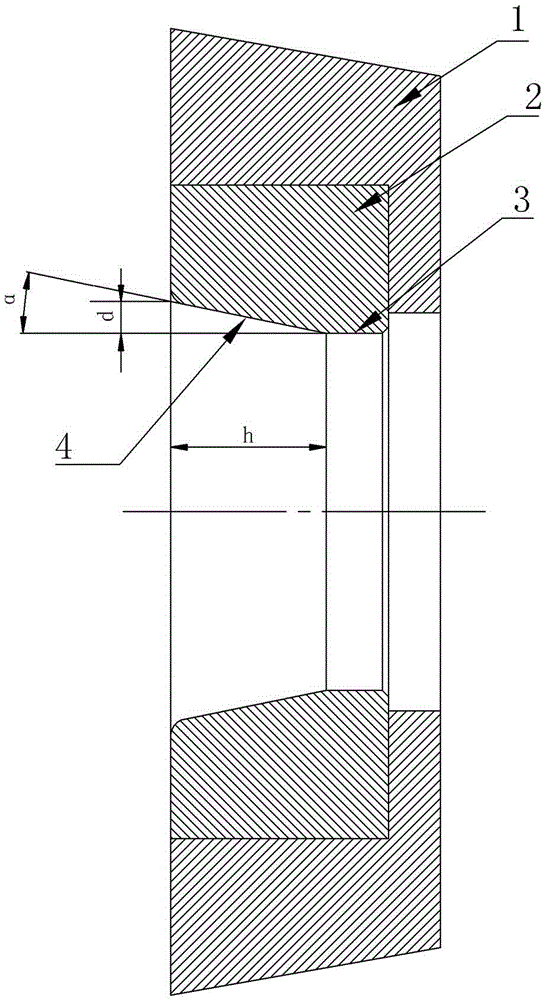

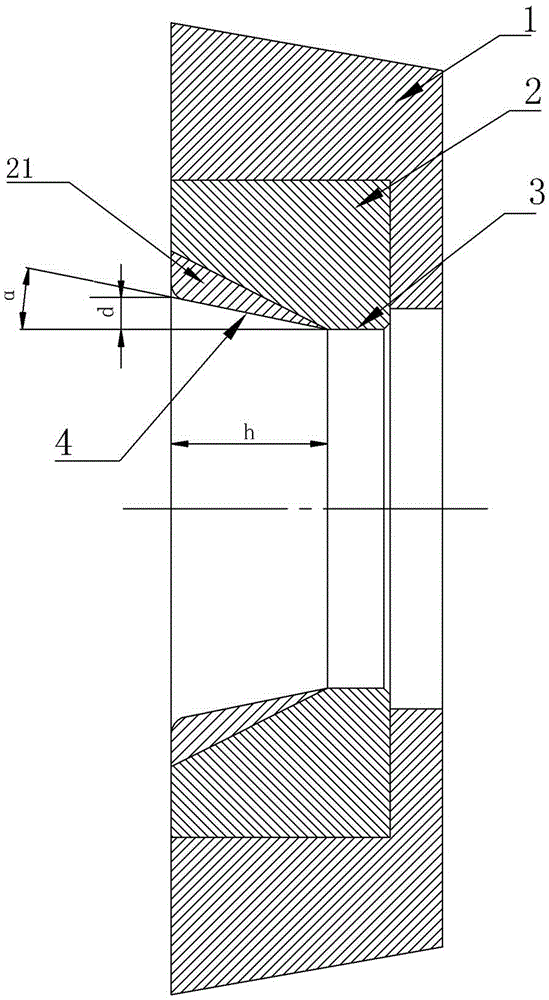

Tube drawing mold

InactiveCN105251791ACorrected Wall ThicknessUniform wall thicknessDrawing mandrelsDrawing diesTube drawingMaterials science

The invention discloses a tube drawing mold. The tube drawing mold comprises an outer mold body and an inner mold body. The outer mold body comprises a mold sleeve and a mold core, the mold core is installed in the mold sleeve, and the mold sleeve is installed in a mold base of a tube drawing machine. An inner hole of the mold core comprises a horn opening section and a sizing belt section for determining the outer diameter of a finished tube. An angle a of the horn opening section is calculated according to the outer diameter of a blank tube, the outer diameter of the finished tube and the height of the horn opening section, and the computational formula is tan a=d / h, wherein d is a half of the value obtained by subtracting the outer diameter of the finished tube from the outer diameter of the blank tube, h is the height of the horn opening section, and the angle a can be changed within the range from -2 degrees to 4 degrees. The mold core is composed of a core body and a core, the core body is installed in the mold sleeve, and the core is installed in the core body. When the steel tube is drawn through the tube drawing mold, the tube drawing mold has the beneficial effects that the product quality can be improved, the product yield can be increased, energy, time and cost can be saved, and the cost can be reduced.

Owner:HENGYANG HONGYUAN PIPE IND CO LTD

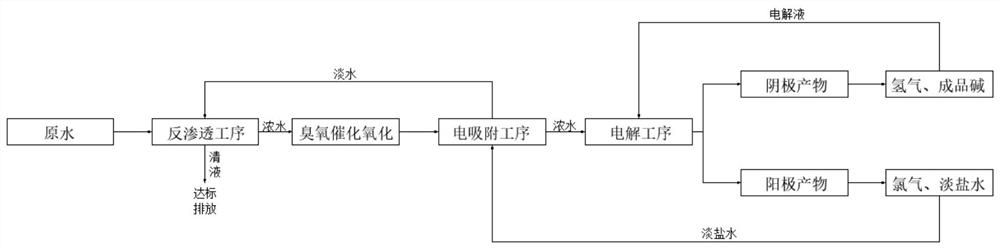

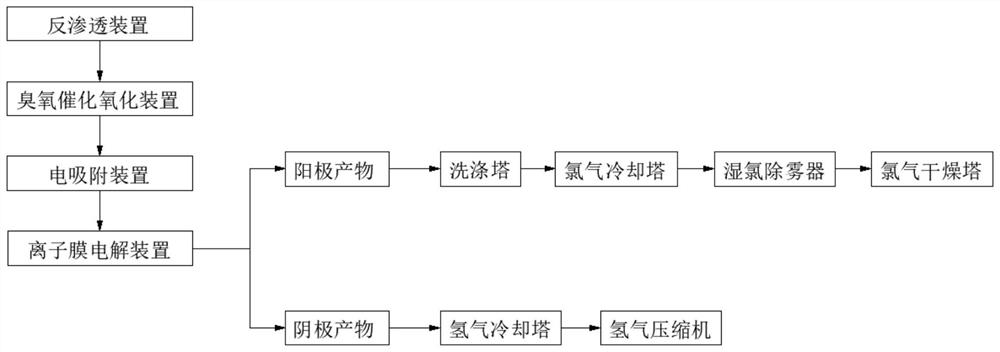

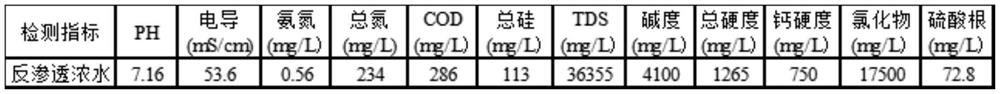

Method and system for producing hydrogen from landfill leachate

PendingCN113200633AReduce engineering investment costLow running costElectrolysis componentsWater contaminantsChemistryHydrogen production

The invention discloses a method and a system for producing hydrogen from landfill leachate, and belongs to the technical field of hydrogen production. The method comprises the steps that concentrated liquor produced in a reverse osmosis process flows into a catalytic ozonation process; clear brine generated in the ozone catalytic oxidation process is sent to the electro-adsorption process, strong brine generated in the electro-adsorption process is sent to the electrolysis process, and light brine generated in the electro-adsorption process is returned to the reverse osmosis process; light salt brine and chlorine flow out of the anode of the electrolysis process, and finished alkali and hydrogen flow out of the cathode of the electrolysis process; chlorine and hydrogen are respectively fed into the chlorine treatment process and the hydrogen treatment process to respectively generate finished chlorine and finished hydrogen which reach the standard, so that the purposes of preparing hydrogen for a fuel cell and co-producing a disinfectant by utilizing the landfill leachate membrane concentrated solution are achieved, and the problem of hydrogen waste generated by a traditional brine electrolysis technology is solved.

Owner:DONGFANG BOILER GROUP OF DONGFANG ELECTRIC CORP

Process for synthesizing N-ethyl piperazidine

ActiveCN1962649BMaterial requirements are highThe three wastes are difficult to deal withOrganic chemistryMetal/metal-oxides/metal-hydroxide catalystsAlcoholBromine

The invention discloses a synthesizing method of N-ethyl piperazine, which comprises the following steps: adopting Cu-Co-M0 / Al2O3 as catalyst with 1-70% Cu, 1-90% Co,1-30% Mo, 0.1-10% Ni, 0.05-10% Mn, 0.01-5.0% Mg, 0.01-5.0% Cr and Al2O3; setting the pressure of liquid phase at 0.1-10.0Mpa under 80-350 Deg C in the interval course with surplus piperazidine; making the molar rate of piperazidineand alcohol at 0.5-10.0 with 0.1-5.0% catalytic cracking quantity.

Owner:ZHEJIANG XINHUA CHEM +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com