Method and system for producing hydrogen from landfill leachate

A landfill leachate and hydrogen technology, which is applied in chemical instruments and methods, contaminated groundwater/leachate treatment, water/sludge/sewage treatment, etc., can solve hydrogen waste and other problems, and achieve low operating costs and engineering investment low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] The current membrane concentrate treatment process is mainly a variety of evaporation processes, such as mechanical vapor recompression (MVR), submerged fuel; the operating cost of MVR is 80-120 yuan / m3, and frequent cleaning is required during operation, which cannot run stably ; The operating cost of submerged combustion is 140-260 yuan / m3. The system has high requirements for heat sources, and the construction and operation energy consumption costs are high. Moreover, these evaporation processes are prone to produce hazardous waste of mixed salts that are difficult to handle.

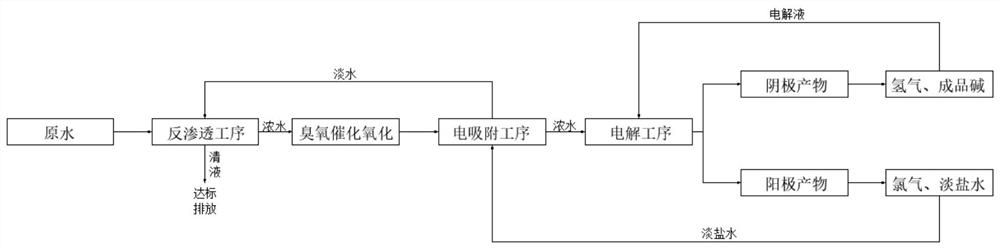

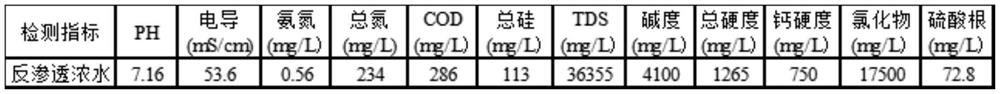

[0058] In view of the defects of the above-mentioned membrane concentrate treatment process, a method for producing hydrogen from landfill leachate is provided in this embodiment. Taking the leachate reverse osmosis membrane concentrate as an example, this method is compatible with other industrial wastewater (such as: leachate ) compared with the reverse osmosis membrane concentrate treatment ...

Embodiment 2

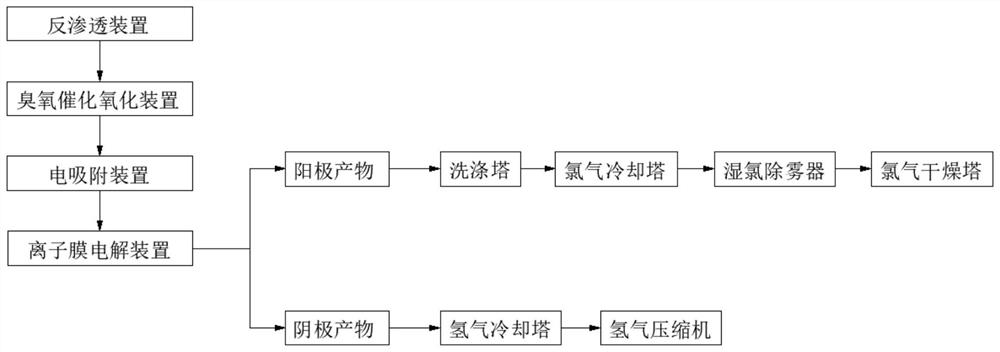

[0080] The present invention also provides a system for producing hydrogen by using landfill leachate. In this embodiment, when the system is working, the raw material used is the leachate reverse osmosis membrane concentrate. For the convenience of transportation and flexible use, the entire device of the system can be assembled and designed as skid-mounted modules. Specifically, such as figure 2 As shown, the system includes:

[0081] ① reverse osmosis device, the inlet end of the reverse osmosis device is connected to raw water;

[0082] ②Advanced ozone oxidation device, the advanced ozone oxidation device is connected to the outlet of the reverse osmosis device and receives the concentrate; under the action of the advanced ozone oxidation device, the COD of the suspended matter in wastewater after advanced ozone oxidation is controlled below 100mg / L .

[0083] ③ electro-adsorption device, the electro-adsorption device is connected with the outlet end of the ozone advan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com